Heating cloth and weaving method thereof

A heating cloth and heating wire technology, applied in the field of home textile fabrics, can solve the problems of comfort and skin-friendly influence, potential safety hazards, and poor electrothermal conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

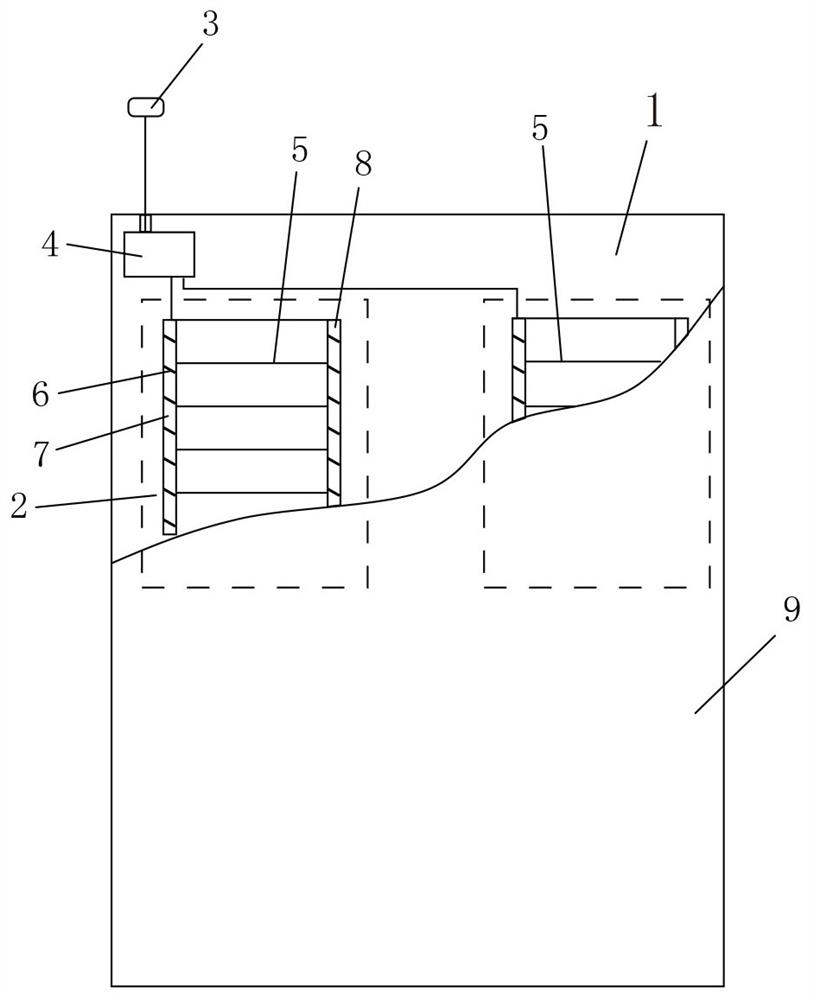

[0022] according to figure 1 , a heating cloth of the present invention, comprising a base fabric layer 1, several heating units 2, and a switch control unit 4 electrically connected to a power supply unit 3, the heating units 2 are divided into several and distributed on the base fabric layer 1 or entirely covered on the base cloth layer 1, the heating unit 2 includes interconnected flexible carbon heating wires 5, positive electrodes 7 and negative electrodes 8 respectively composed of electrode wires 6, and the flexible carbon heating wires 5 are connected to each other. Between the positive electrode 7 and the negative electrode 8, the flexible carbon heating wire 5, the electrode wire 6 and the base fabric layer 1 are interwoven with each other, and the twisting degree of the flexible carbon heating wire 5 is 200- 600 twists / m, preferably 300 twists / m, fineness <500 denier. The distribution density of the flexible carbon heating wires 5 in the base cloth layer 1 is 60-50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com