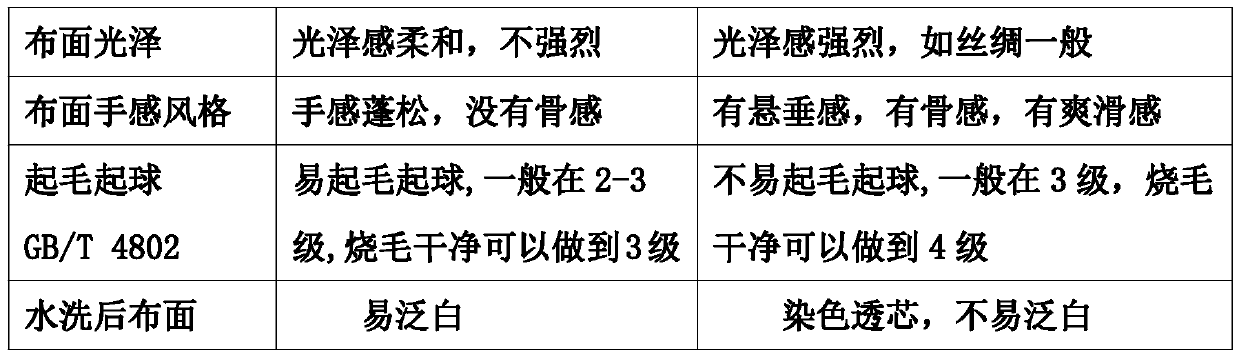

Production process of pure viscose fabric

A production process and fabric technology, applied in the direction of fabric surface trimming, wear-resistant fibers, heating/cooling fabrics, etc., can solve the problems of easy to scratch the skin, easy to wrinkle and wrinkle of pure viscose fabrics, and achieve improvement Easy to wrinkle and pilling, improve the effect of easy wrinkling and pilling, not easy to wrinkle and pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1. The production process of pure viscose fabric comprises the following steps:

[0019] The first step, adopting potassium hydroxide solution to carry out mercerizing treatment to the bleached cloth of viscose fabric, obtains A product;

[0020] In the second step, overflow dyeing is done on product A to obtain product B;

[0021] The third step is to rearrange product B to obtain product C;

[0022] In the fourth step, product C is pre-shrunk to obtain a finished product.

[0023] The potassium hydroxide solution has a concentration of 200-210 g / l.

[0024] The temperature of the potassium hydroxide solution is 20-40°C.

[0025] The specific process of mercerizing is as follows: firstly use the potassium hydroxide solution in the washing machine to process the bleached cloth of the viscose fabric to obtain the a1 product; product; do ventilation treatment on product a2 for 3 minutes.

[0026] During the ventilation treatment, keep the radial tension of t...

Embodiment 2

[0032] Example 2. The production process of pure viscose fabric comprises the following steps:

[0033] The first step, adopting potassium hydroxide solution to carry out mercerizing treatment to the bleached cloth of viscose fabric, obtains A product;

[0034] In the second step, overflow dyeing is done on product A to obtain product B;

[0035] The third step is to rearrange product B to obtain product C;

[0036] In the fourth step, product C is pre-shrunk to obtain a finished product.

[0037] The potassium hydroxide solution has a concentration of 200 g / l.

[0038] The temperature of the potassium hydroxide solution was 20°C.

[0039] The specific process of mercerizing is as follows: firstly use the potassium hydroxide solution in the washing machine to process the bleached cloth of the viscose fabric to obtain the a1 product; product; do ventilation treatment on product a2 for 3 minutes.

[0040] During the ventilation treatment, keep the radial tension of the a2 ...

Embodiment 3

[0049] Example 3. The production process of pure viscose fabric comprises the following steps:

[0050] The first step, adopting potassium hydroxide solution to carry out mercerizing treatment to the bleached cloth of viscose fabric, obtains A product;

[0051] In the second step, overflow dyeing is done on product A to obtain product B;

[0052] The third step is to rearrange product B to obtain product C;

[0053] In the fourth step, product C is pre-shrunk to obtain a finished product.

[0054] The potassium hydroxide solution has a concentration of 205 g / l.

[0055] The temperature of the potassium hydroxide solution was 30°C.

[0056] The specific process of mercerizing is as follows: firstly use the potassium hydroxide solution in the washing machine to process the bleached cloth of the viscose fabric to obtain the a1 product; product; do ventilation treatment on product a2 for 3 minutes.

[0057] During the ventilation treatment, keep the radial tension of the a2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com