Substitute alkali for dyeing of dark reactive dyes

A technology of reactive dyes and substitute alkali, which is applied in the field of dyeing and finishing, can solve the problems of insufficient color depth of fabrics, difficult to achieve the color depth of soda alkali, and low color fixing rate of substitute alkali.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

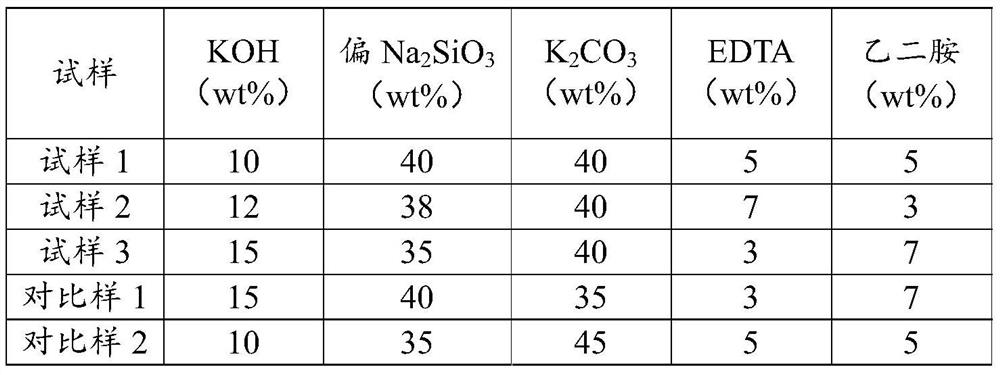

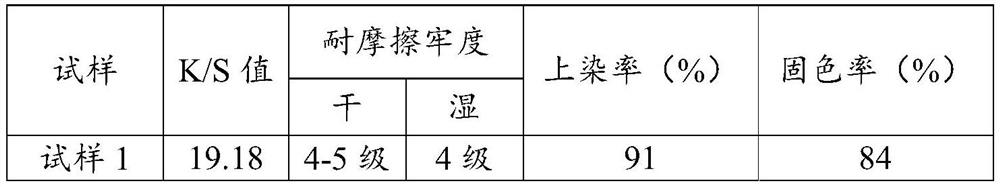

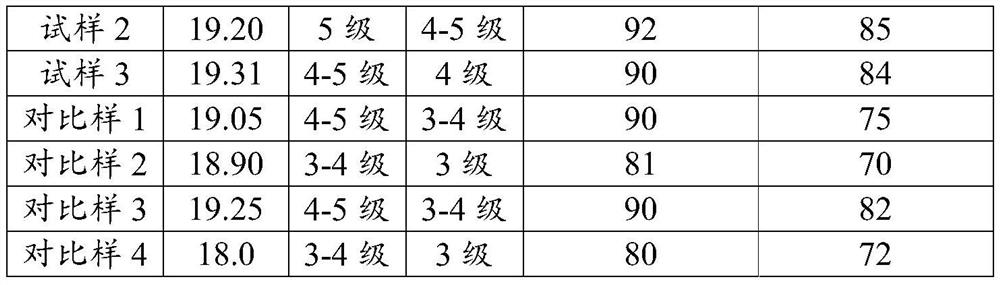

[0020] In this embodiment, red dye is taken as an example to illustrate the dyeing effect of the substituted base of the present invention on dark dyes. This embodiment provides a substituted base for dyeing dark reactive dyes, including the following components by weight percentage: KOH 10wt%~15wt %, partial Na 2 SiO 3 30wt% ~ 45wt%, K 2 CO 3 35wt% ~ 45wt%, EDTA 3wt% ~ 7wt%, ethylenediamine 3wt% ~ 7wt%; the specific sample and comparison sample formulations are shown in Table 1, and soda ash (20% owf) is used as the comparison sample 3 to fix the color. Alkali is sold as contrast sample 4, and the processing method of each sample is as follows:

[0021] Fabric dyeing formula: reactive red BH-3BS 4% owf, soda ash 20g / L, samples 1-3 and comparison samples 1 and 2 with a concentration of 3% owf, salt 40g / L, liquor ratio 1:10.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap