Device for improving mixing efficiency of slurry and soil of mixing pile

A mixing efficiency, cement-soil mixing pile technology, applied in soil protection, sheet pile walls, construction, etc., can solve the problems of inability to spray grout, failure to achieve uniform mixing of grout and reinforced soil, blockage, etc., to ensure spraying. The effect of pulp uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

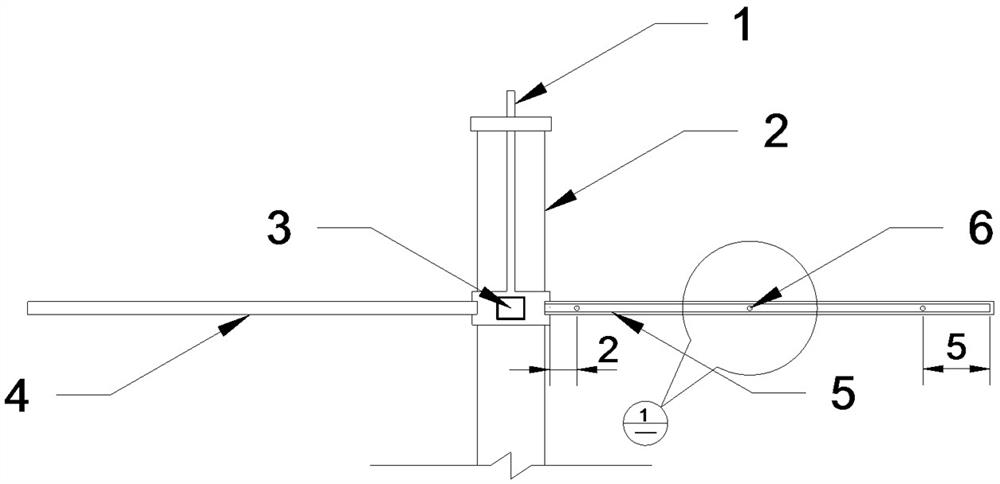

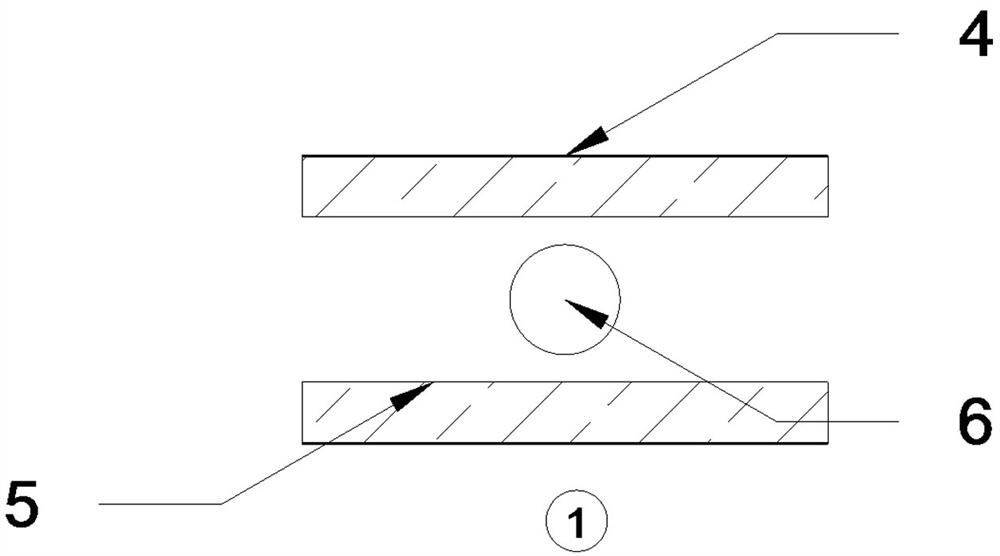

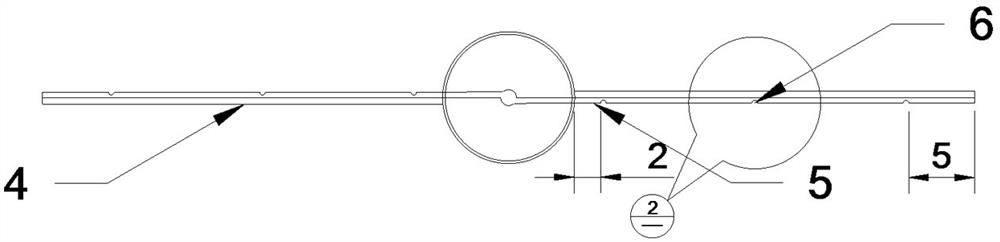

[0033] Embodiment one, with reference to figure 1 : A device for improving the uniformity of cement-soil mixing pile slurry in soft soil reinforcement, including a slurry delivery pipe 1, a stirring shaft 2, a pressure sensor 3, a stirring blade 4, a spray pipe 5, a spray hole 6, and an elastic stop Back to valve 7.

[0034] When the mixer reaches the designated pile position, the center of the mixing head is aligned with the designed pile position. The mixer sinks while stirring, and the sinking speed is controlled by the motor. When the mixer sinks to a certain depth, the slurry is mixed according to the mix ratio determined by the design pile strength requirements. The amount of slurry is determined by the spraying in the construction process. The number of times is determined, and the slurry is poured into the collecting hopper before grouting. After the mixer sinks to the design depth, turn on the mud pump to inject the slurry into the foundation for soft soil reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com