Method for preparing liquid metal strain sensor and liquid metal strain sensor

A technology of strain sensor and liquid metal, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problem of sensor failure and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

[0027] The core of the present invention is to use the liquid-solid conversion characteristics of liquid metal, and to prepare a high-sensitivity liquid metal strain sensor combining soft and hard through the multiple curing process of two different elastic modulus silica gels. The strain sensor prepared by this method can ensure high Sensitivity can reach more than 150% strain without fracture.

[0028] A method for preparing a liquid metal strain sensor, specifically comprising the following processes:

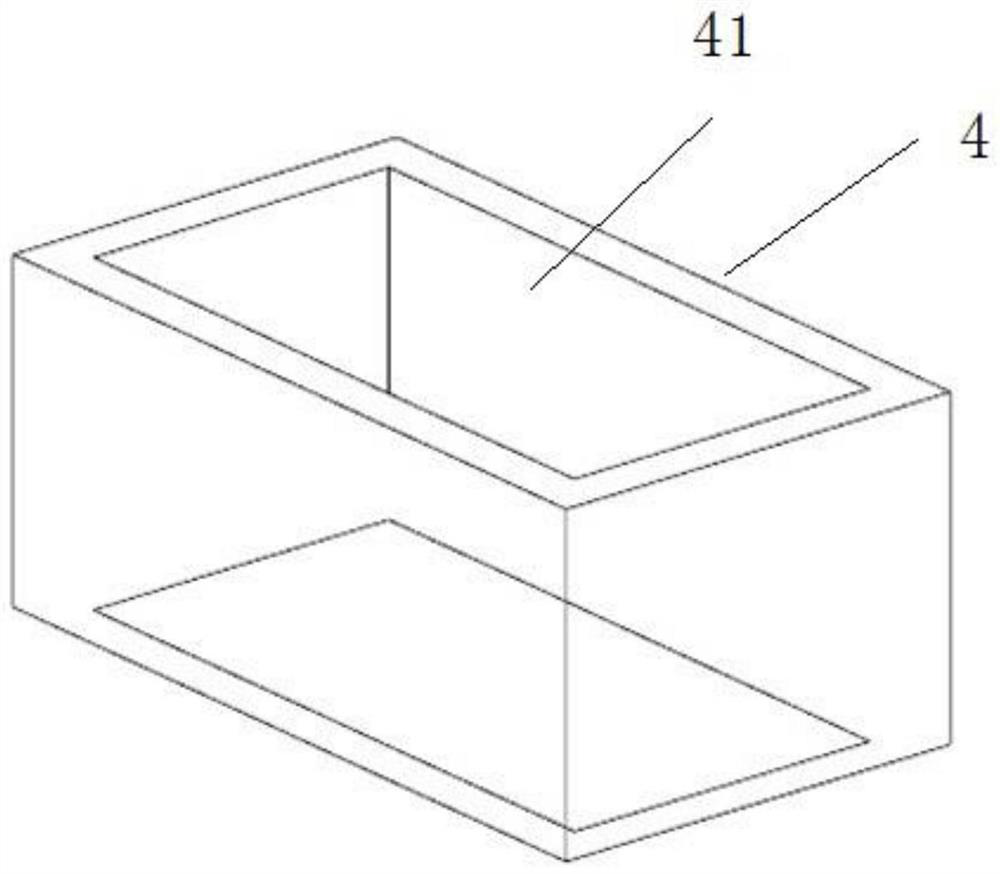

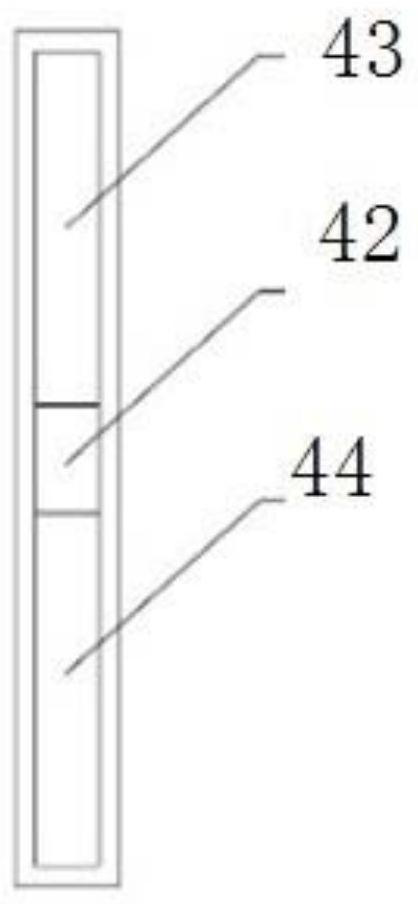

[0029] 1. Using mold method (mold such as figure 2 Shown) The modulus of elasticity of the prepared Shenzhen Hongye silica gel is 2.77×10 6 The E635 material of Pa is an embedded body 2 with a size of 2×2×4 mm. A liquid metal wire 1 is used to wind the embedded body 2. The liquid metal wire 1 is divided into a winding part 11 and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com