Five-axis linkage series-parallel machine tool structure

A five-axis linkage and hybrid technology, applied in manipulators, program-controlled manipulators, metal processing machinery parts, etc., can solve the problems of small driving force, slow response speed, small acceleration, etc., and achieve large motion acceleration, fast response speed, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

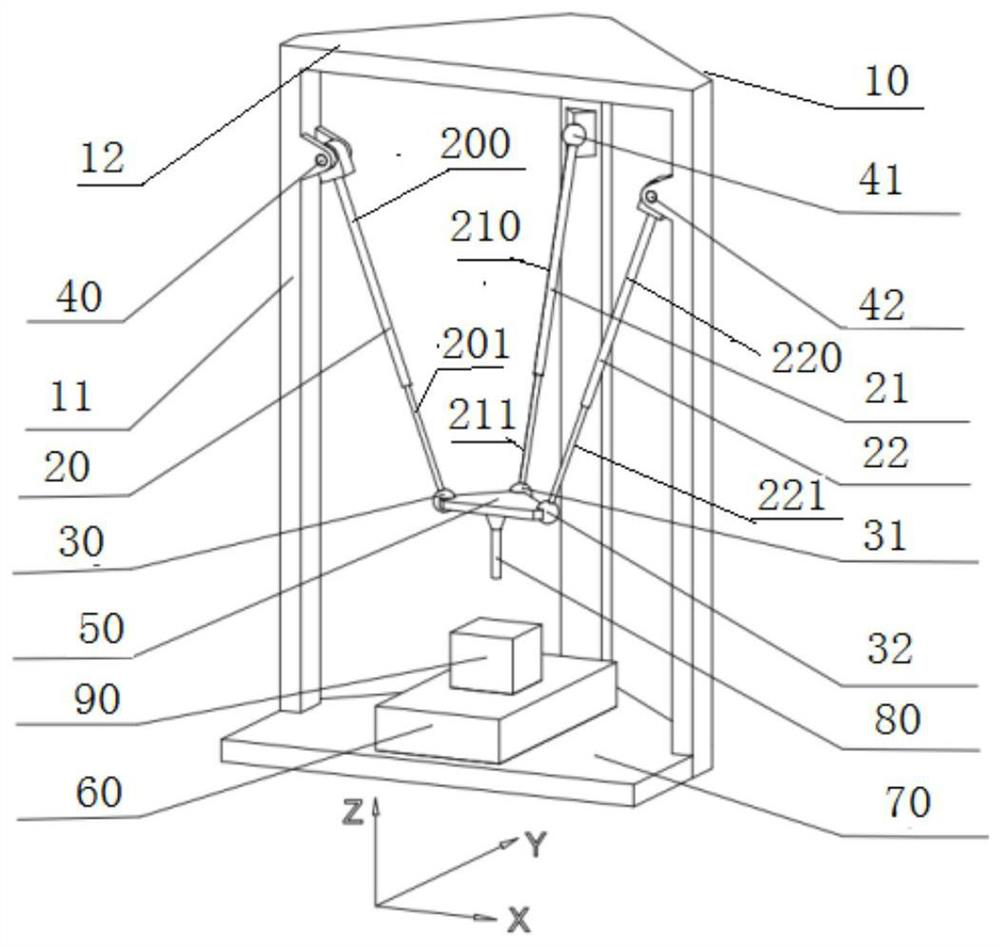

[0026] see figure 1 As shown, the five-axis linkage hybrid machine tool structure of the present invention includes a work frame 10 including three columns 11 and a triangular positioning top 12, branch chain I20, branch chain II21, branch chain III22, rotating part I30, rotating part II31, rotating part III32, rotating pair I40, rotating part IV41 and rotating pair III42, the moving platform 50 whose size is smaller than the positioning top 12 of the working frame 10 and whose shape is also triangular, and the workbench 60, the bed 70 and the cutting tool 80; The three columns 11 of the work stand 10 are all perpendicular to the positioning top 12 and the bed 70, and their tops are respectively connected to the positioning top 12 at a corner of the triangular positioning top 12, and the bottom ends are respectively connected to the bed 70; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com