PVC pipe cutting mechanism

A PVC pipe and cutting mechanism technology, applied in the direction of tubular goods, metal processing, other household appliances, etc., can solve the problems of poor contact of slip rings, stuck ring gear transmission, etc., and achieve the effect of reducing failure rate and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

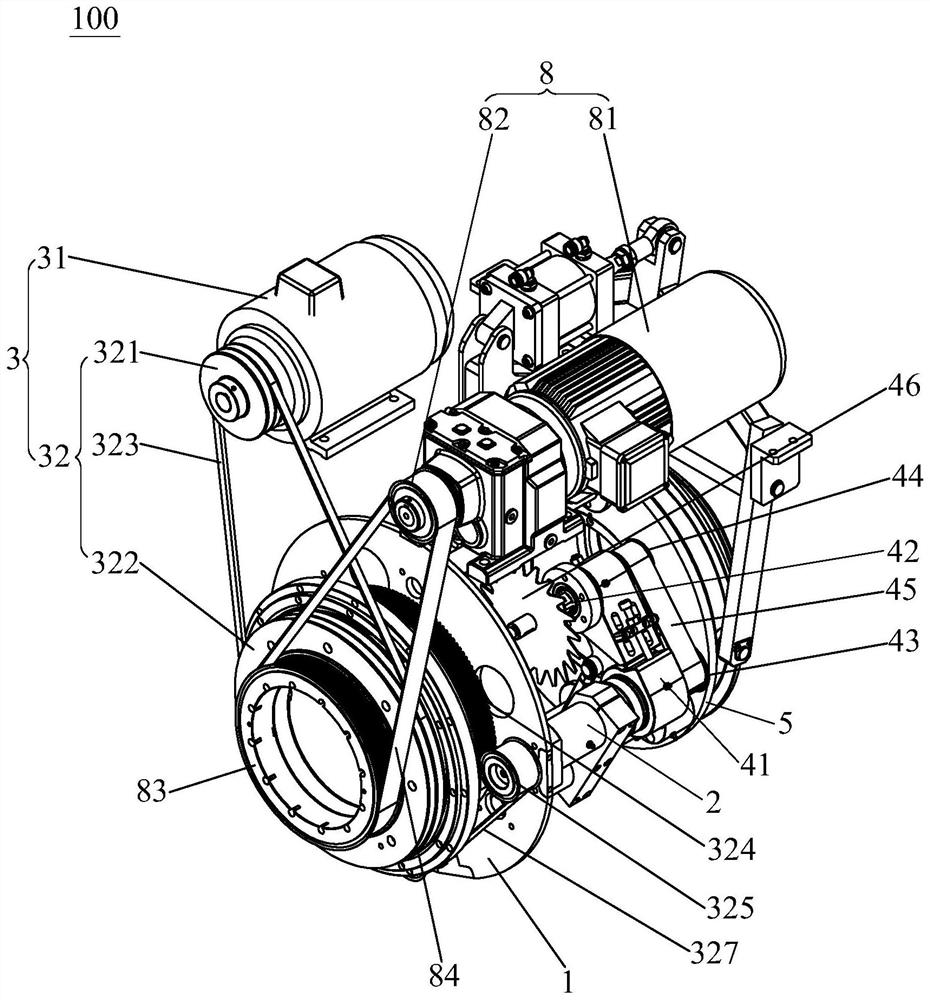

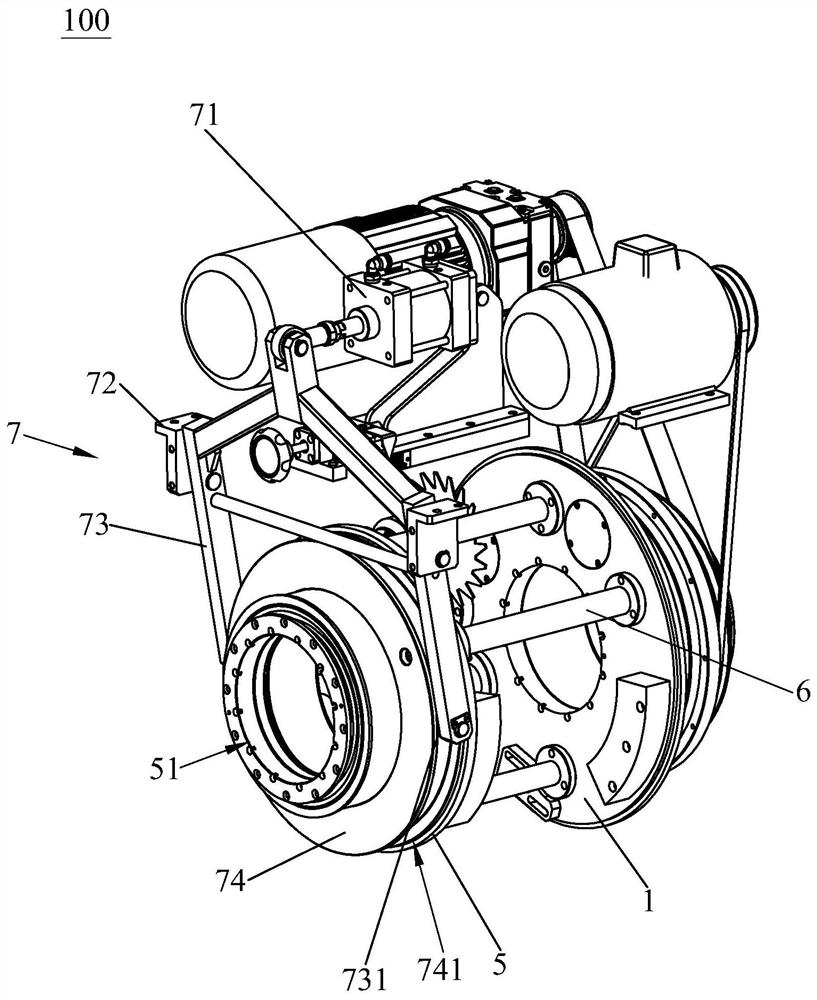

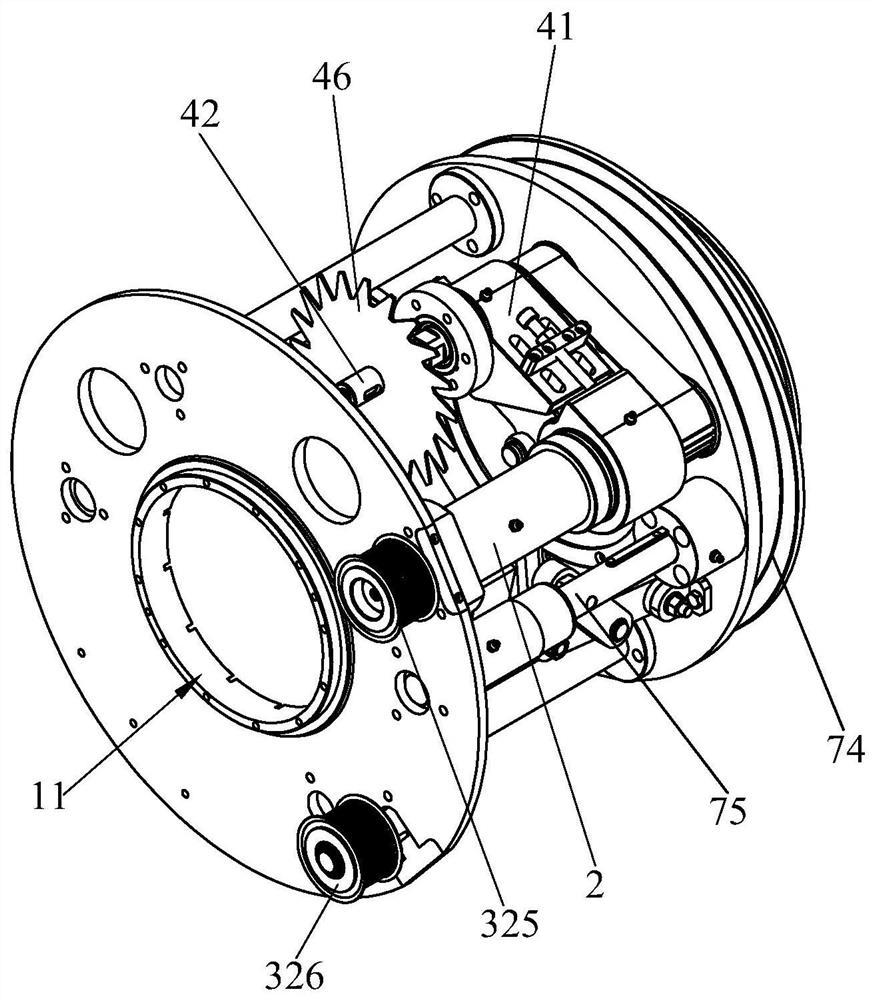

[0021] see Figure 1 to Figure 3 , the PVC pipe cutting mechanism 100 of the present invention includes a first turntable 1, a first rotating shaft 2, an autorotation drive mechanism 3, a swing arm 41, a second rotating shaft 42, a first autorotation synchronous wheel 43, a saw blade synchronous wheel 44, and a saw blade synchronous Part 45, saw blade 46, second turntable 5, fixing member 6, feed drive mechanism 7 and revolution drive mechanism 8, the first rotating shaft 2 is rotatably installed on the first turntable 1, the rotation drive mechanism 3 and the first The rotating shaft 2 is connected and can drive the first rotating shaft 2 to rotate; one end of the swing arm 41 is rotatably sleeved on the first rotating shaft 2, and the second rotating shaft 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com