Ternary environment-friendly mixed refrigerant, preparation method thereof and refrigerating system

A mixed refrigerant and refrigeration system technology, applied in chemical instruments and methods, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of poor environmental performance and low GWP of refrigerants, and achieve reduction of irreversible heat transfer losses, good Environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

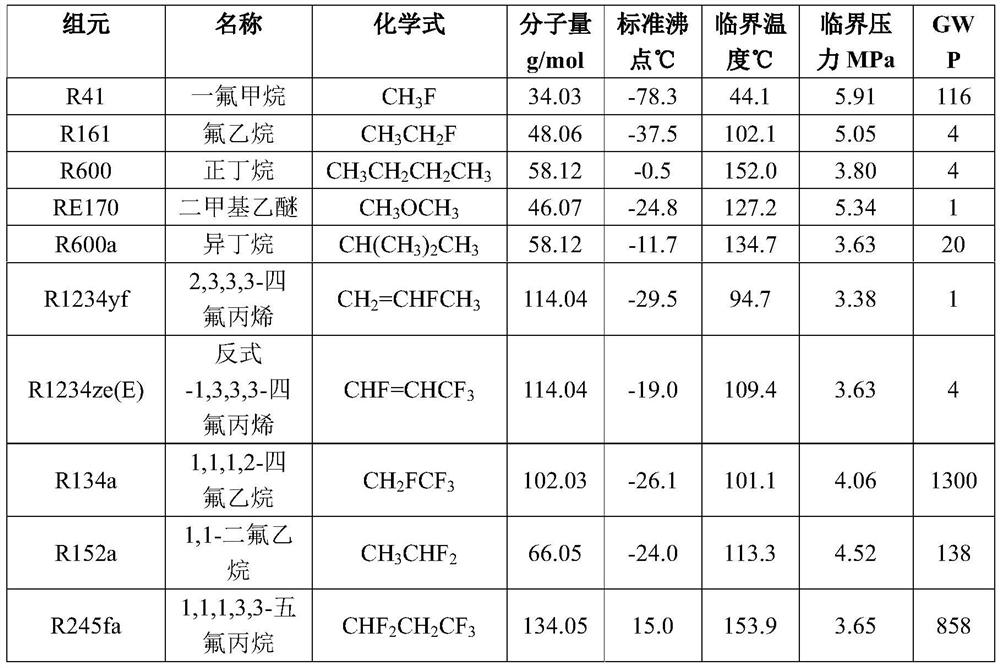

Method used

Image

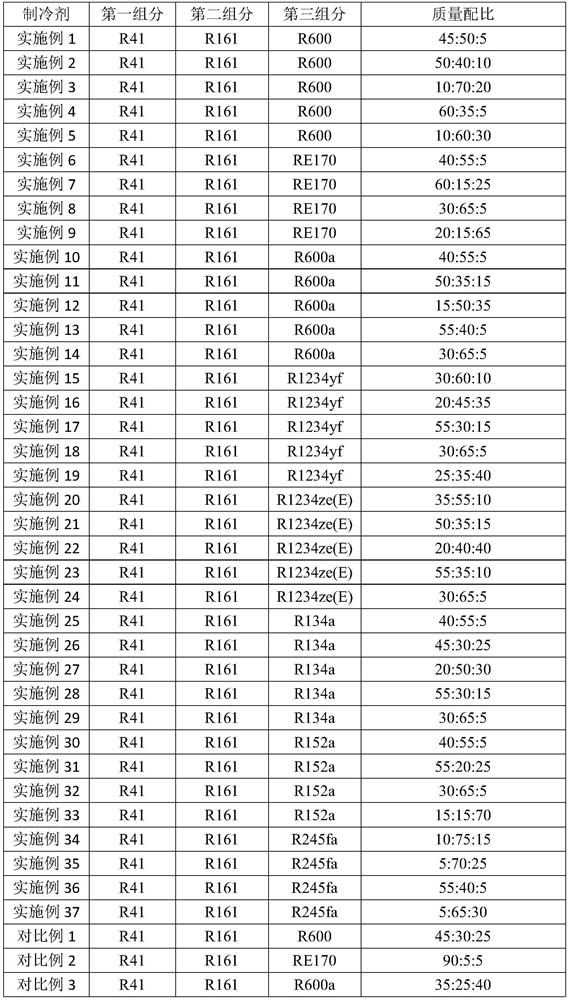

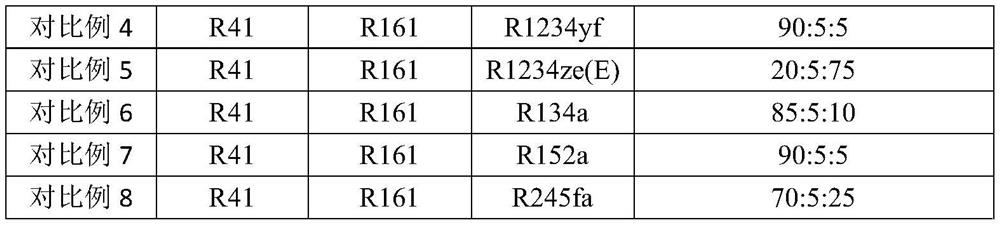

Examples

Embodiment 1

[0026] The three components of monofluoromethane (R41), fluoroethane (R161) and n-butane (R600) are physically mixed in a liquid phase at room temperature in a mass ratio of 45:50:5 to obtain a three-component environmental protection For the mixed refrigerant, the sum of the mass percentages of monofluoromethane (R41), fluoroethane (R161) and n-butane (R600) is 100%.

Embodiment 2

[0028] The three components of monofluoromethane (R41), fluoroethane (R161) and n-butane (R600) are physically mixed in a liquid phase at room temperature at a mass ratio of 50:40:10 to obtain a three-component environmental protection For the mixed refrigerant, the sum of the mass percentages of monofluoromethane (R41), fluoroethane (R161) and n-butane (R600) is 100%.

Embodiment 3

[0030] The three components of monofluoromethane (R41), fluoroethane (R161) and n-butane (R600) are physically mixed in a liquid phase at room temperature at a mass ratio of 10:70:20 to obtain a three-component environmental protection For the mixed refrigerant, the sum of the mass percentages of monofluoromethane (R41), fluoroethane (R161) and n-butane (R600) is 100%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap