Multifunctional supporting assembly for assisting foundation pit construction and construction method of multifunctional supporting assembly

A multi-functional, foundation pit technology, which is applied to the accessories of scaffolding, infrastructure engineering, lighting device components, etc., can solve the problems of waste, inconvenient climbing and transportation of foundation pit support, and insufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

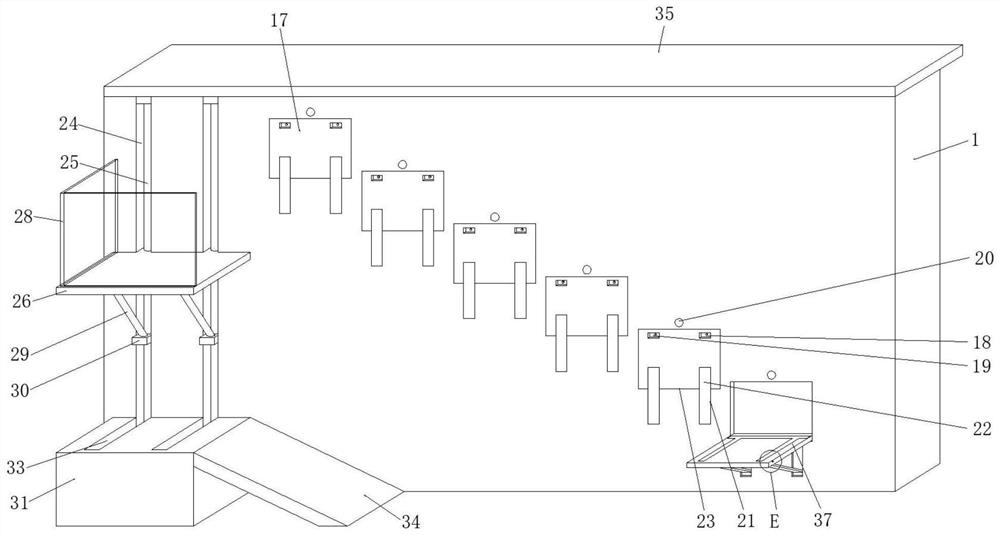

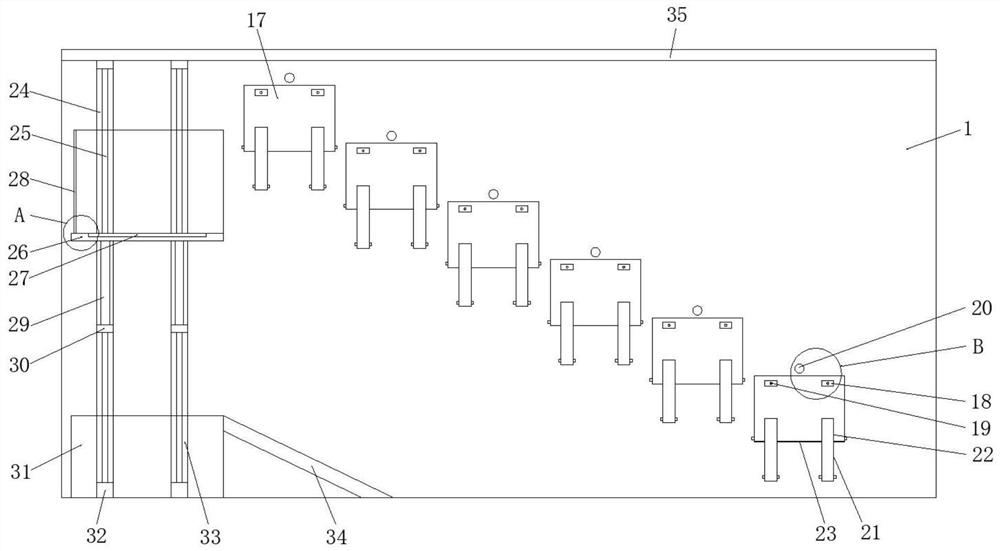

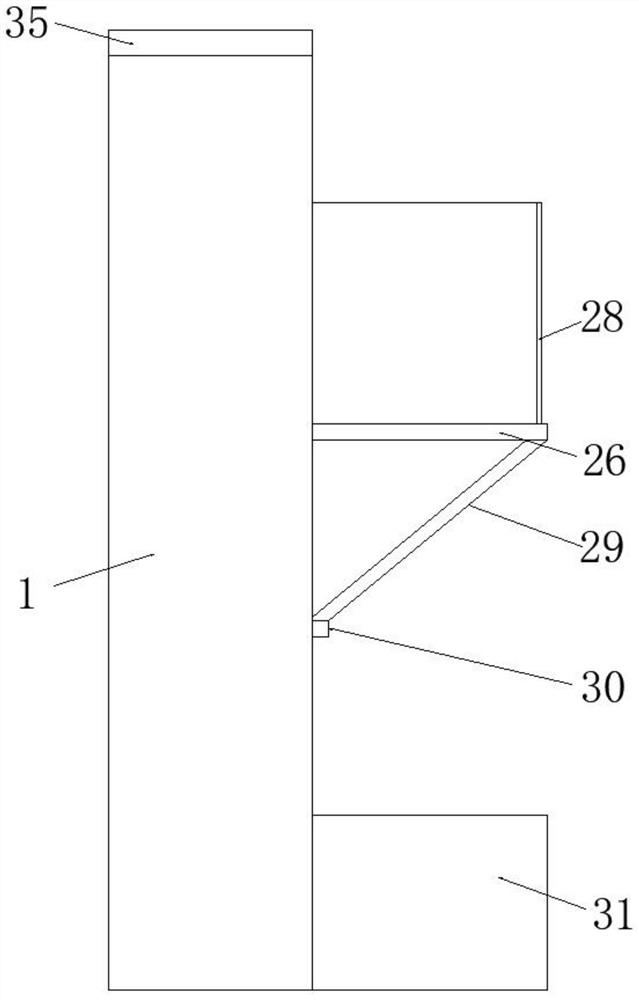

[0054] When in use, hoist the supporting support frame 1 to the edge of the foundation pit and make the side where the limit plate 5 is located be attached to the edge of the foundation pit, start the first DC motors 2 on both sides to rotate the threaded rod 4 so that the push plate 3 realizes direction The interior of the foundation pit wall is advanced and inserted into the interior of the pit wall for fixing, and then the built-in extension insert rod 9 is nailed into the depth of the foundation pit wall for reinforcement. After the fixing is completed, the upper pedal 35 is installed on the top of the support frame 1, The ladder fixed inserting rod 21 is overturned to an inclined state, and then the ladder pedal 17 is turned over to a horizontal state, and one end of the ladder fixed inserting rod 21 is inserted into the inside of the oblique bar slot 18 to fix the ladder pedal 17, and the ladder fixed inserting rod 21 is inserted into the oblique Press the sensor light sw...

Embodiment 2

[0056] When in use, hoist the supporting support frame 1 to the edge of the foundation pit and make the side where the limit plate 5 is located be attached to the edge of the foundation pit, start the first DC motors 2 on both sides to rotate the threaded rod 4 so that the push plate 3 realizes direction The interior of the foundation pit wall is advanced and inserted into the interior of the pit wall for fixing, and then the built-in extension rod 9 is nailed into the depth of the foundation pit wall for reinforcement, and the reverse hook fixing ring 15 and reverse hook 16 hook the soil to make the support support The frame 1 is nailed into the soil more stably. After fixing, the upper pedal 35 is installed on the top of the supporting support frame 1, the ladder fixing inserting rod 21 is turned over to an inclined state, and then the step pedal 17 is turned over to a horizontal state. One end of the ladder fixed inserting rod 21 is inserted into the inside of the inclined r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com