Solid rocket engine ignition device wire fixing combined mechanism

A technology for ignition devices and solid rockets, which is applied in the direction of rocket motor devices, machines/engines, jet propulsion devices, etc., can solve the problems that the environmental adaptability and reliability of ignition devices cannot be guaranteed, and the development and production of unfavorable missile models can be solved, so as to achieve improvement Environmental adaptability and working reliability, avoiding wire fatigue and aging, and eliminating the effects of damage modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In these drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

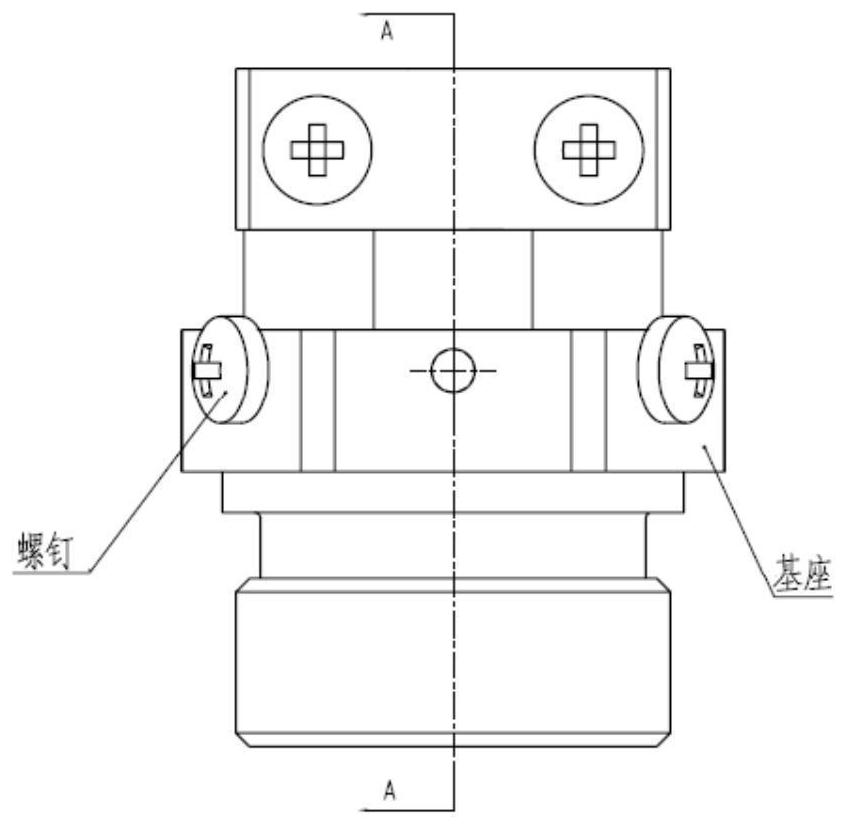

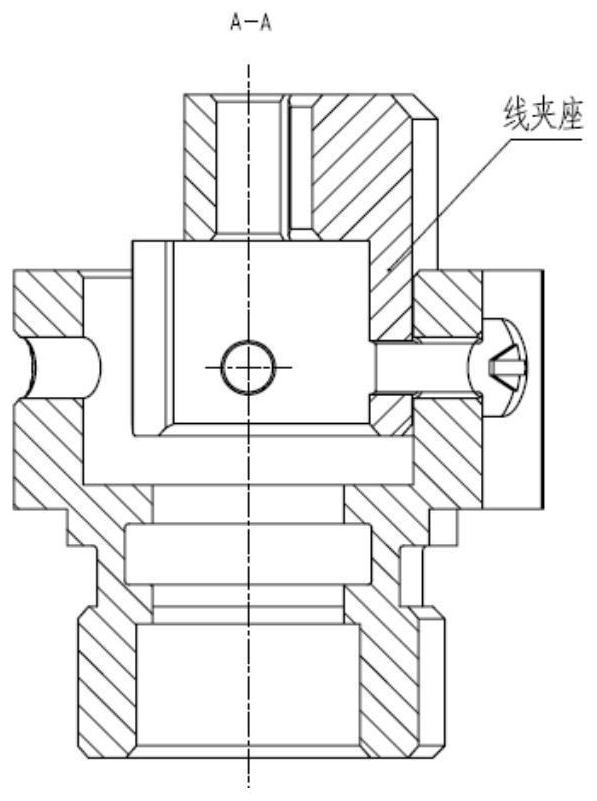

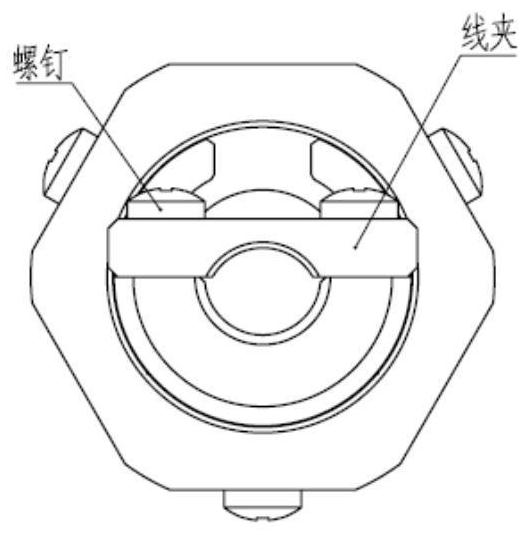

[0032] figure 1 It is a schematic diagram of a solid rocket motor ignition device wire fixing combination mechanism of the present invention. The fixing wire combination mechanism has been applied in the development of a certain type of solid rocket motor, including: a base, a wire clamp seat, a wire clamp and a screw.

[0033] The base is made of TC4 titanium alloy metal material; the clamp seat and the clamp are both mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com