Engine numerical control system using stepping motor

A stepping motor and numerical control system technology, applied in the direction of machines/engines, engine components, charging systems, etc., can solve the problem of inaccurate control of engine fuel flow, poor performance of fuel flow control, poor performance of pump regulators, etc. problems, to achieve the effect of solving unsatisfactory engine performance, reducing precision problems and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

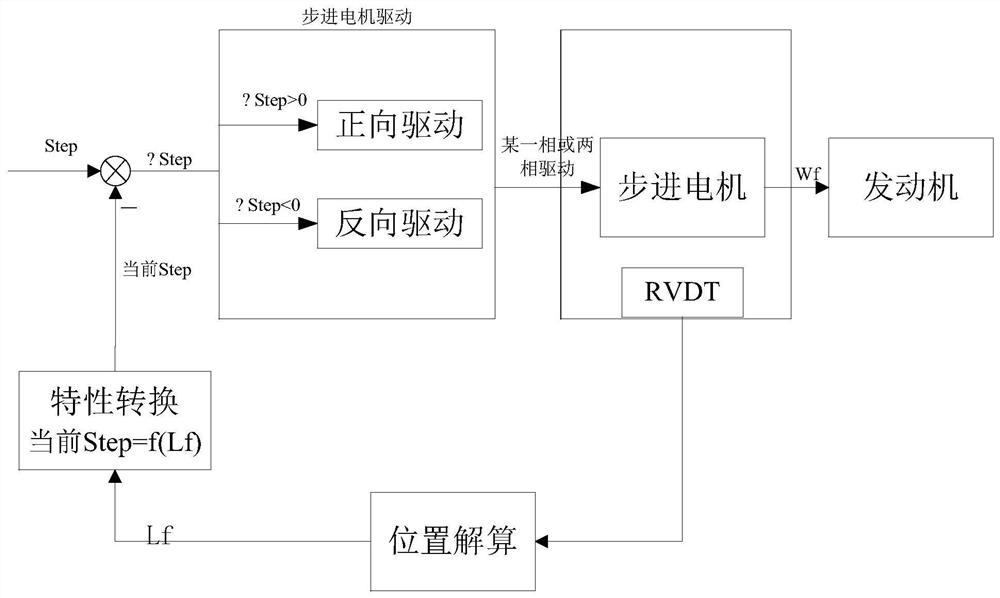

[0015] Such as figure 1 As shown: In order to effectively avoid the influence of the sampling accuracy deviation of the oil needle RDVT sensor on the control quality and improve the reliability of the engine numerical control system, the present invention includes the engine numerical control system body, the actuator of the fuel pump regulator in the engine numerical control system body Including stepper motor;

[0016] When the fuel flow is controlled by the stepper motor, the given step number Step of the stepper motor is determined by the given amount of fuel. Oil needle position Lf, and determine the current step number step of the stepper motor according to the current oil needle position Lf;

[0017] Determine the step difference between the given step number Step and the current step number Step, and correct the rotation steps of the stepping motor ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com