Air-drop fire extinguishing bomb empennage device

A technology of fire extinguishing bombs and fins, which is applied in the field of fire extinguishing bombs, can solve the problems of high assembly skill requirements, large cumulative errors, complex assembly processes, etc., and achieve the effect of low processing cost and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the purpose and advantages of the present invention, the content of the invention will be further described below in conjunction with the accompanying drawings and examples.

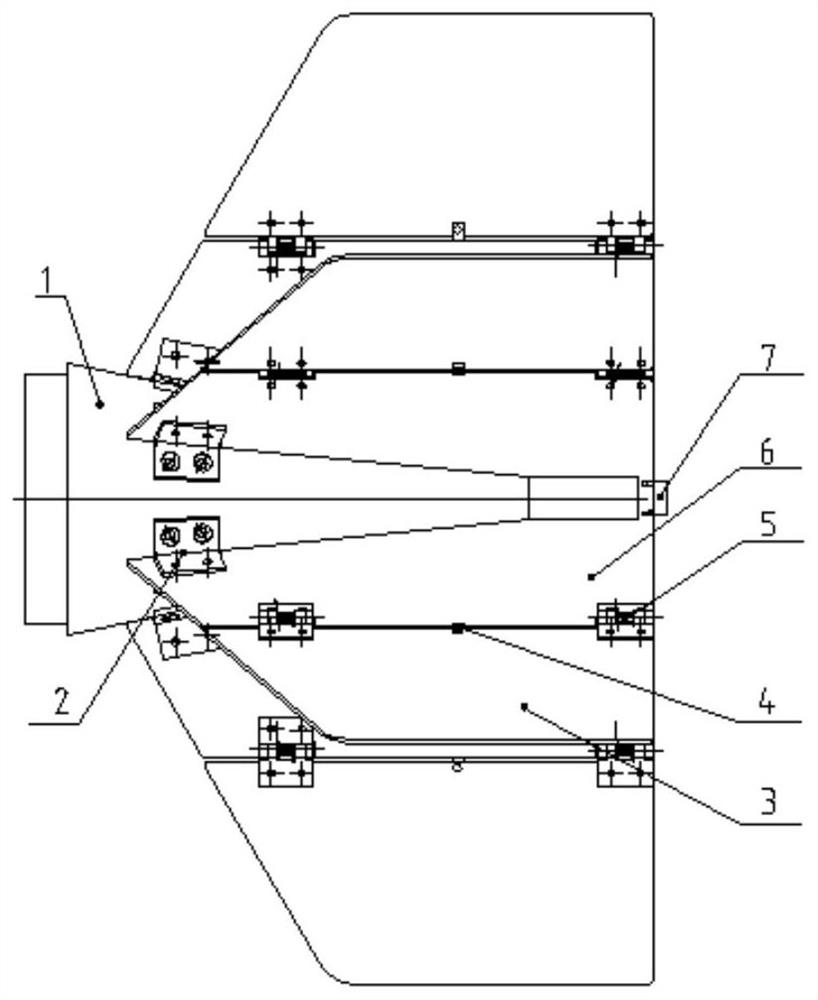

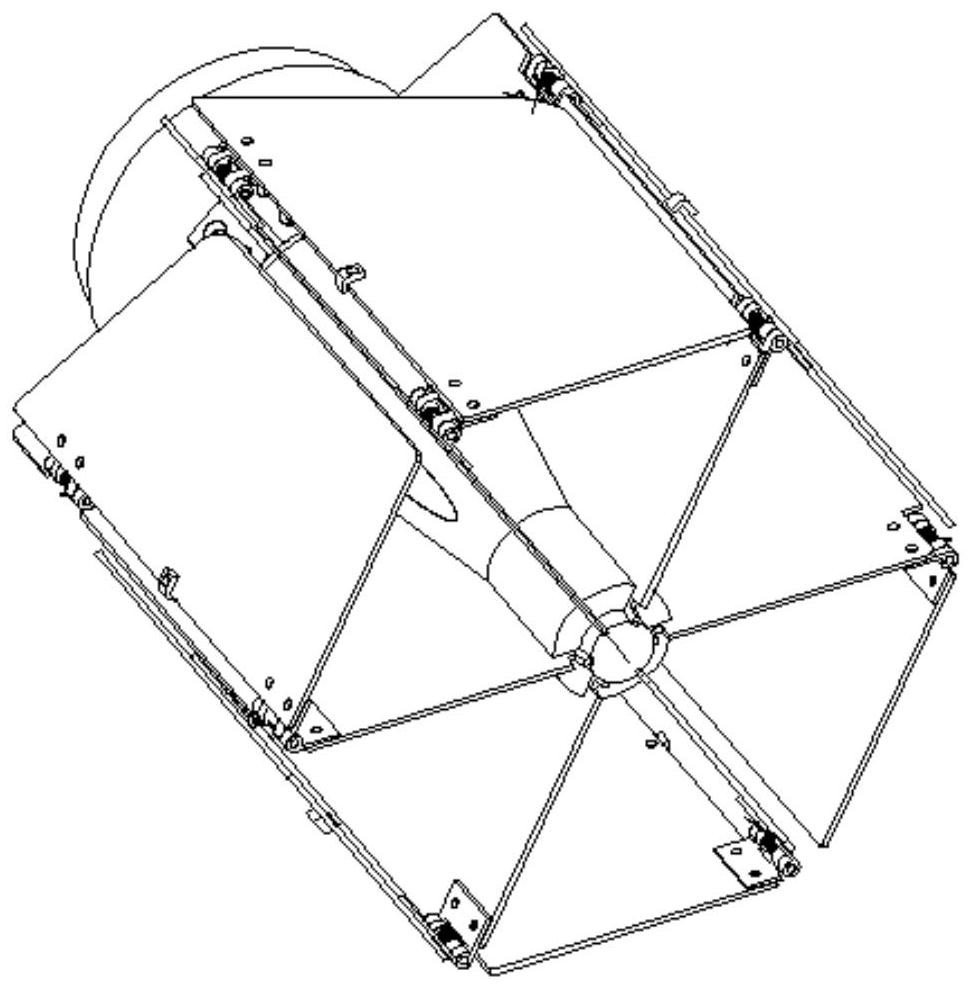

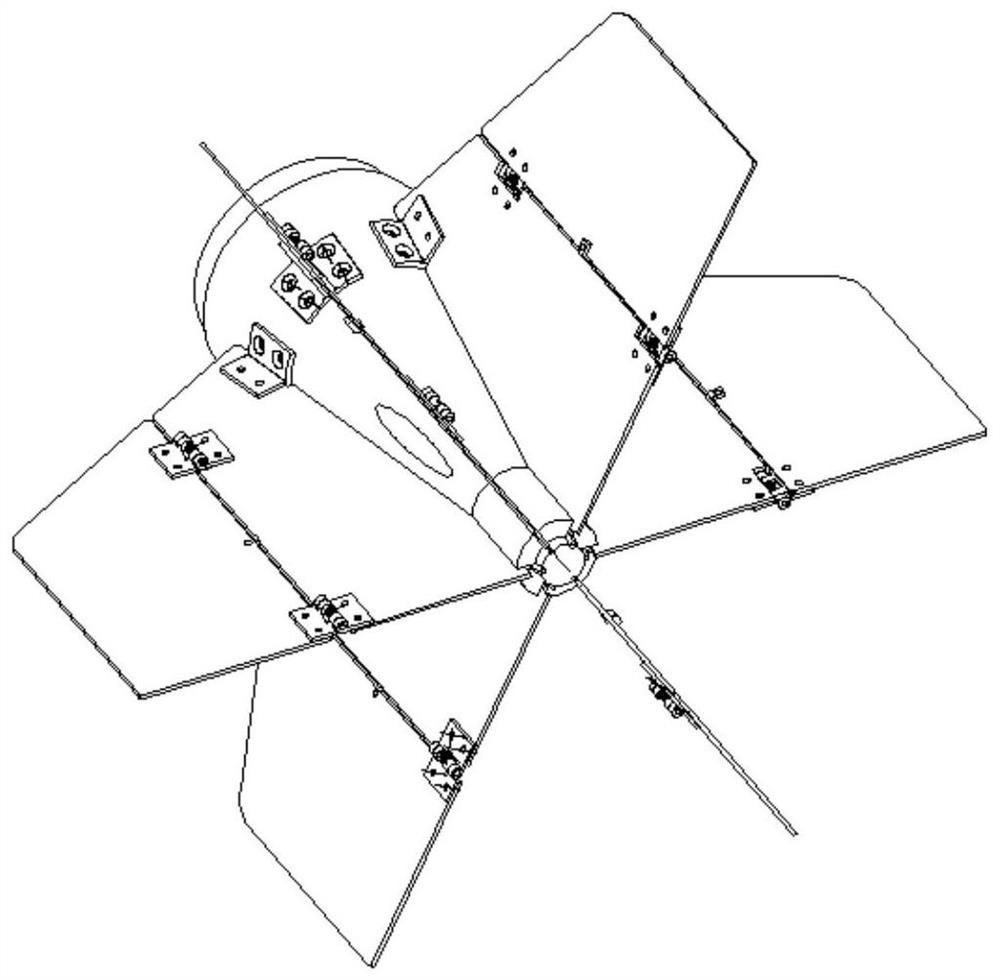

[0024] As a kind of tail device capable of stably guiding the fire extinguishing bomb to fly vertically downward in the airdrop environment, the present invention adopts a large wing surface, a large wingspan, and a folding tail structure. Such as figure 1 As shown, it includes an empennage body 1, a fixed block 2, an upper airfoil 3, a positioning spacer 4, a spring hinge 5, a lower airfoil 6, and a screw plug 7.

[0025] The 3rd and 6th sides of the upper and lower wings adopt a straight-plate airfoil structure with chamfered leading edges. , the other edges are rounded. The upper and lower airfoils 3 and 6 are all made of ordinary plates through direct punching and molding, including the mounting holes on the airfoils and the rounding around the airfoils, and no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com