Electrostatic spinning emitting electrode

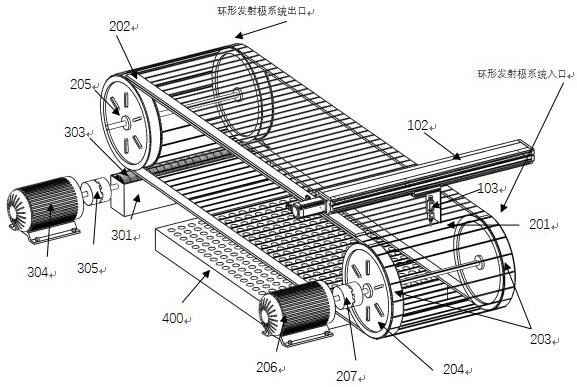

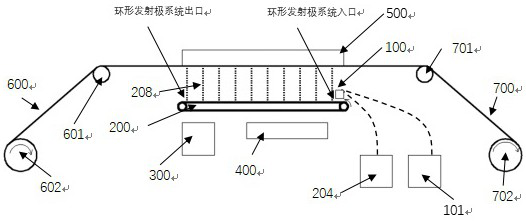

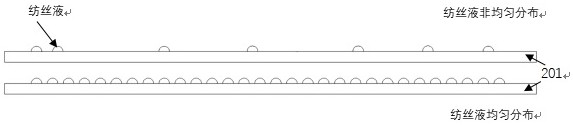

An electrospinning, emitter technology, applied in textiles and papermaking, filament/thread forming, spinneret assemblies, etc., can solve problems such as uneven distribution of spinning solution, droplet splashing, and electric field interference between jets , to avoid maintenance difficulties, avoid uneven thickness, and avoid easy blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] An electrospinning emitter described in the present invention prepares nanofiber waterproof composite fabrics. The electrospinning nanofiber waterproof composite fabric is made by compounding an electrospinning waterproof nanofiber film and a polyester fabric. Therefore, the nanofibrous membrane used needs to be uniform and have a thickness of 20 μm. In order to meet the above requirements, the nanofiber material used is PVDF.

[0034] Dissolve PVDF in DMF and prepare a 20wt% PVDF / DMF solution as a spinning solution and store it in the storage box 101 for future use.

[0035] DMF is added into the cleaning tank 301 as a cleaning solution, so that the cleaning solution is submerged in a quarter of the height of the cleaning brush head 303 .

[0036] The polyester fabric is placed between the unwinding device 600 and the winding device 700 as the base, and the base moves at a constant speed with a linear speed of 0.1 m / s.

[0037] A rectangular stainless steel strip wi...

example 2

[0052] An electrospinning emitter described in the present invention prepares a nanofiber PET composite filter material with H13 grade. The high-efficiency composite filter material is made by compounding an electrospun nanofiber membrane with high-efficiency filtration performance and a PET base material. Therefore, the nanofiber membrane used needs to be uniform, with an average fiber diameter of 200nm and a thickness of 10μm, so as to achieve the filtration performance of the H13 filtration level. In order to meet the above requirements, the nanofiber material used is PA6.

[0053] Dissolve PA6 in formic acid, configure it as a 12wt% PA6 / acetic acid solution, and store it in the liquid storage box 101 as the spinning solution for future use.

[0054] Acetic acid is added into the cleaning tank 301 as a cleaning solution, so that the cleaning solution is submerged in a quarter of the height of the cleaning brush head 303 .

[0055] Put PET as the substrate between the unwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com