High efficiency cavitation air flotation precipitation machine

A vortex and high-efficiency technology, which is applied in the field of high-efficiency concave vortex air flotation sedimentation machines, can solve the problems of inability to carry out large-scale and wide application, the stability of effluent water cannot be guaranteed, and the water quality requirements of influent water, etc., so as to save equipment, The effect of ingenious design and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

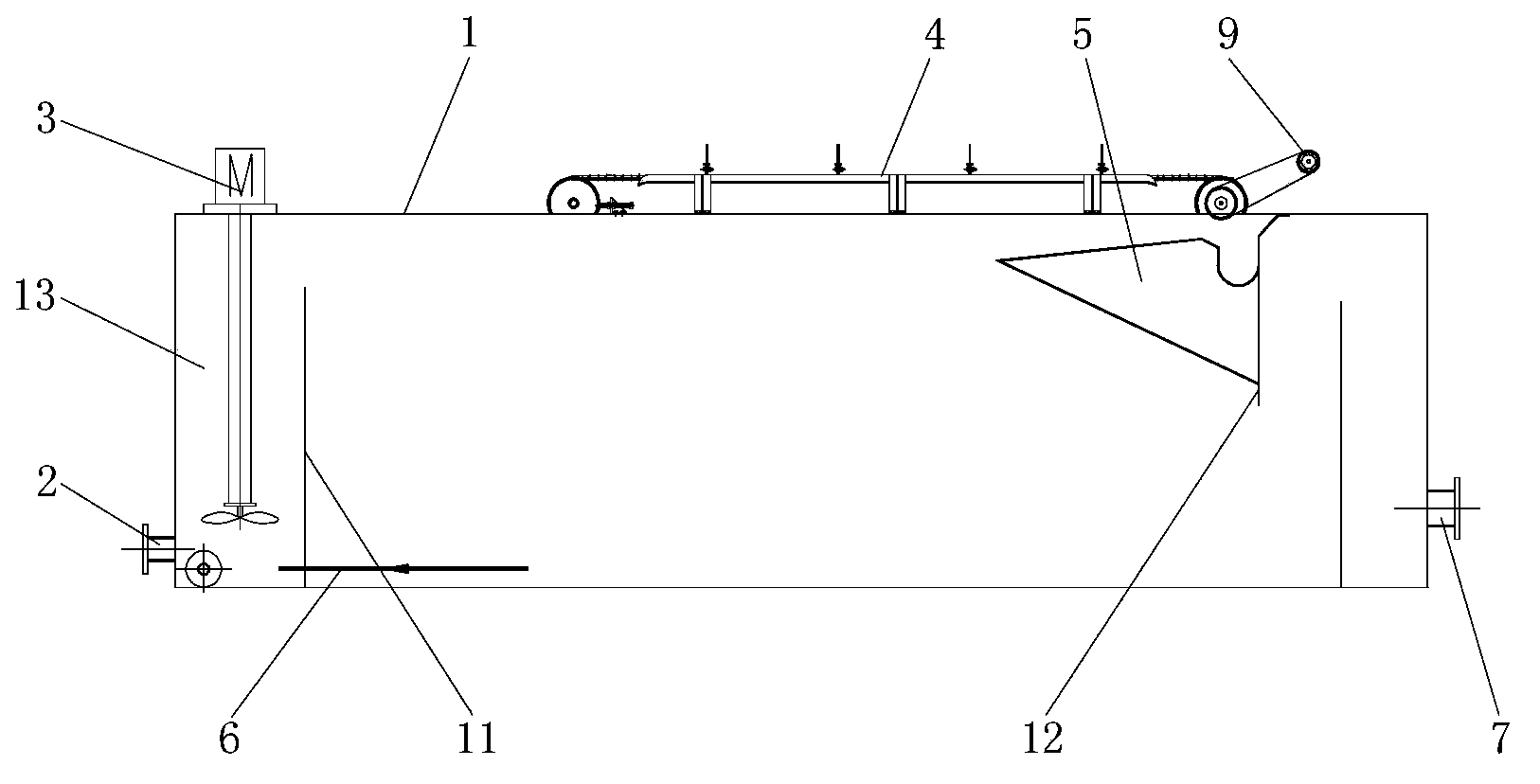

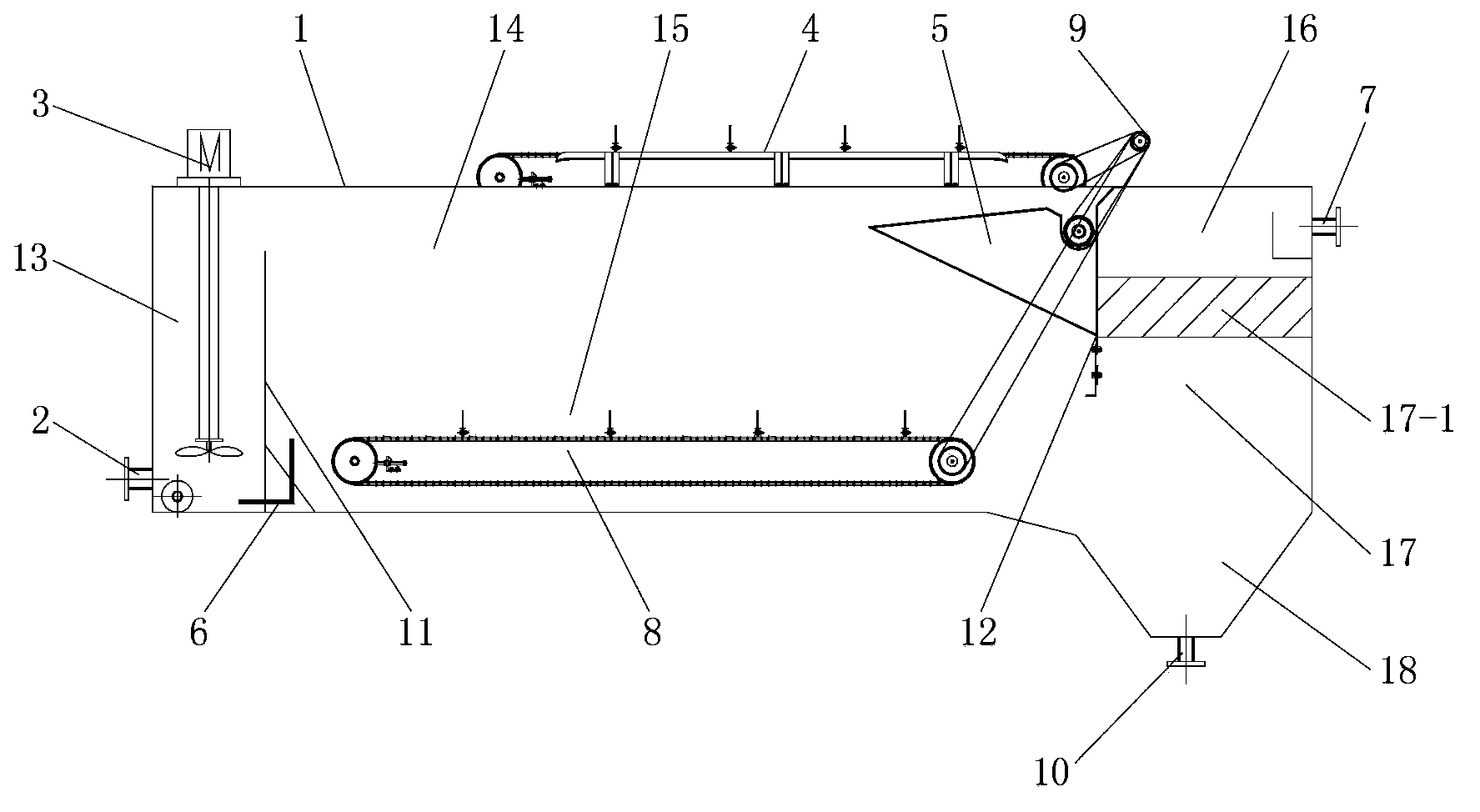

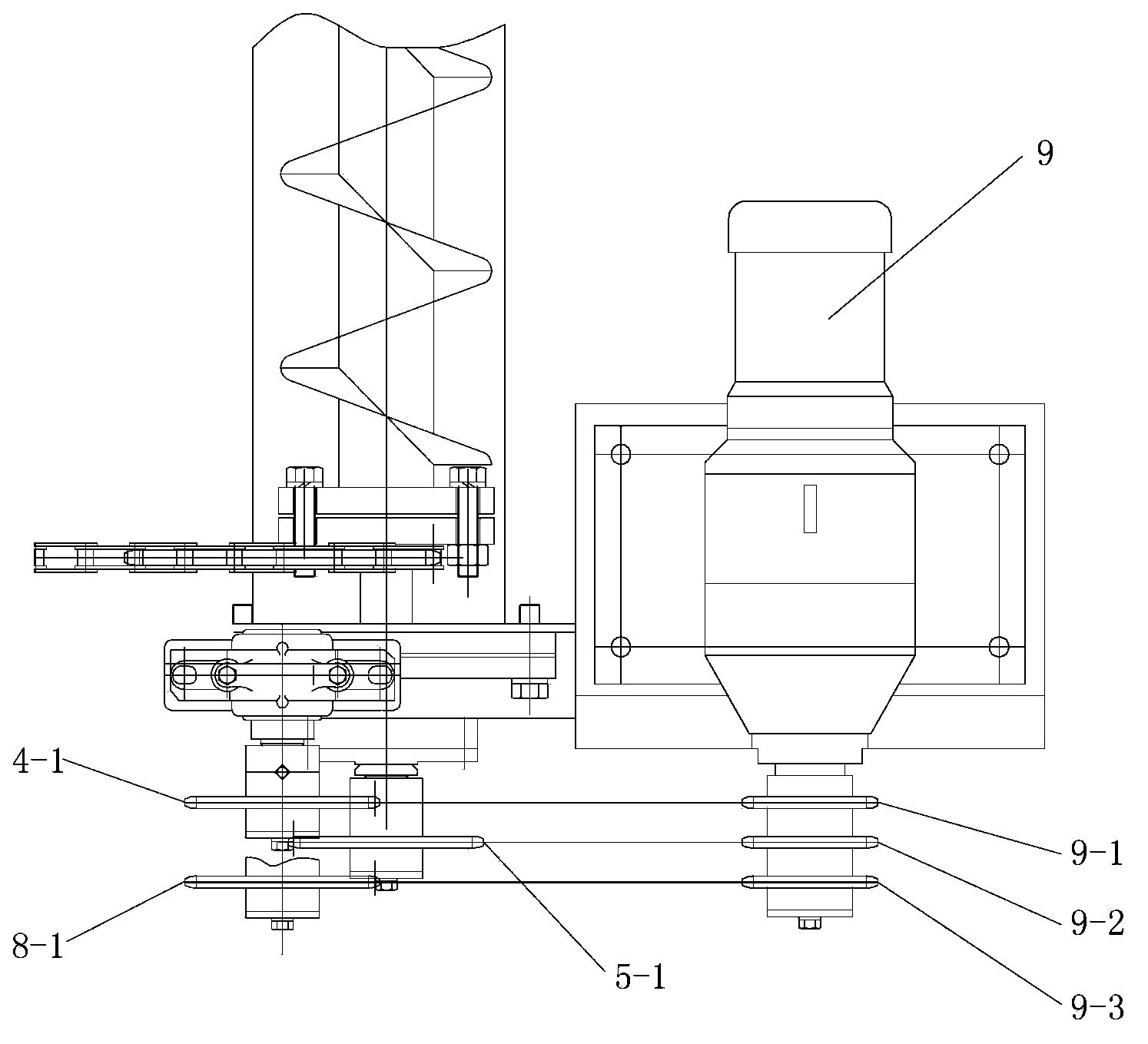

[0014] see figure 2 with image 3 , The present invention includes a pool body 1, a water inlet 2, a vortex air flotation machine 3, a froth scraper 4, a spiral froth conveyor 5, a return pipe 6 and a water outlet 7; the inner left side of the pool body 1 is provided with The left partition 11, the left side area of the left partition 11 is the contact zone 13, the vortex air floatation machine 3 is arranged in the contact zone 13, and the outlet of the contact zone 13 is opened at the upper end; the inner right side of the pool body 1 is arranged There is a right partition 12, between the right partition 12 and the left partition 11 is the treatment area, the foam scraper 4 is arranged at the upper end of the treatment area and fixed on the tank body 1; the spiral foam conveyor 5 is installed on the scraper The bottom right side of the foaming machine 4; the bottom of the contact zone 13 is connected to the treatment zone through the return pipe 6; the treatment zone is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com