Integrally-hoisted movable heat pump tobacco curing barn

A flue-cured tobacco room and heat pump technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as pollution, high cost, and heavy weight, and achieve the effects of reducing manufacturing costs, reducing flue-cured tobacco costs, and improving and optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

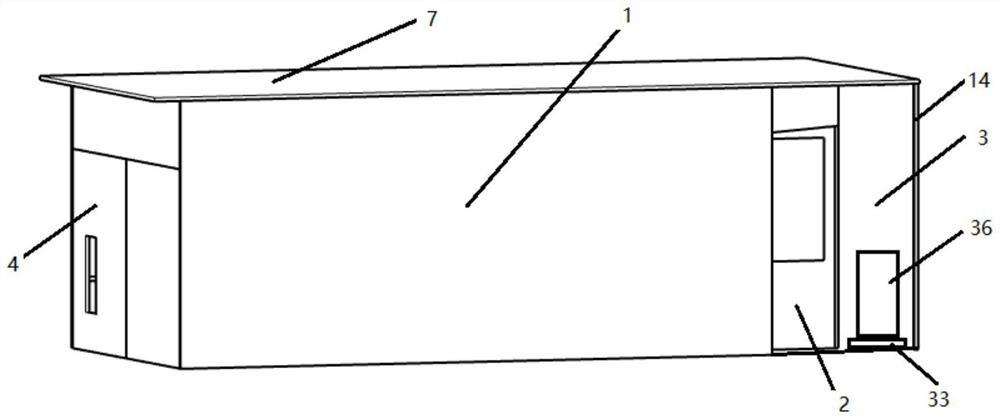

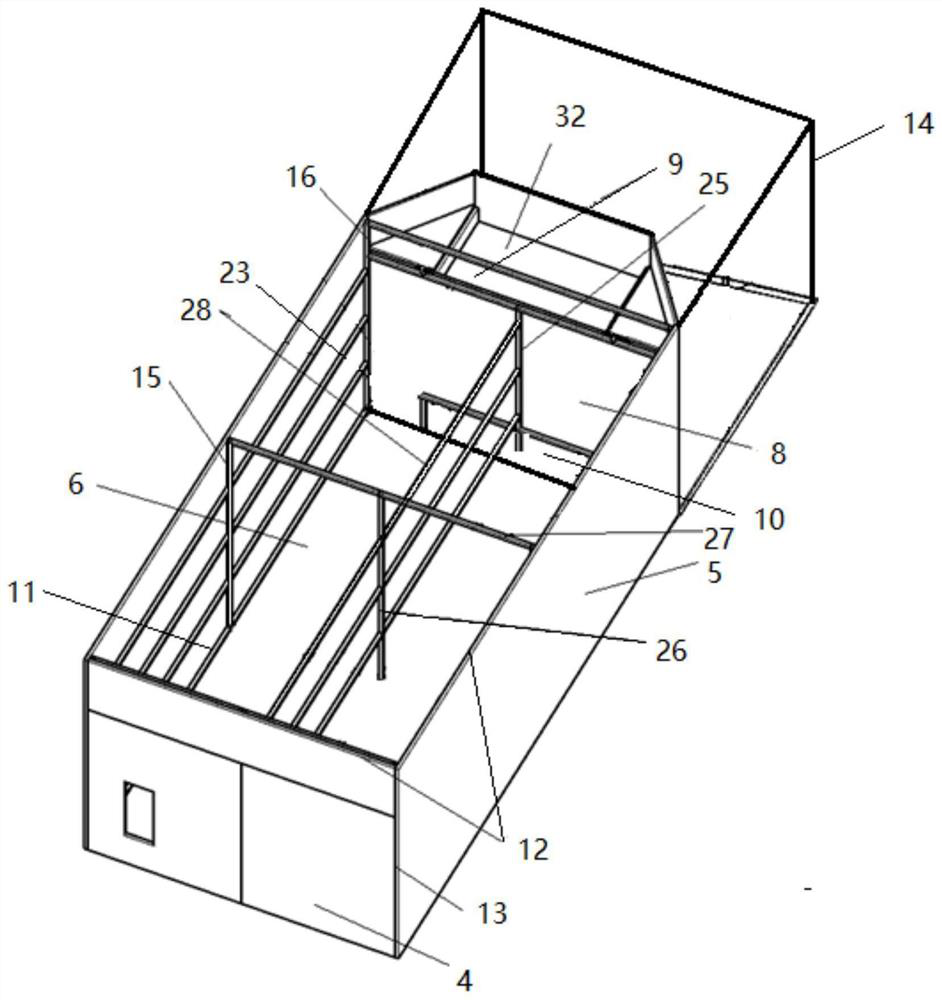

[0039] like figure 1 and figure 2 As shown, a whole hoisting mobile heat pump flue-cured room includes sequentially adjacent smoke-loading room 1, heating room 2, and heat pump placement area 3. The smoke-loading room 1 includes a smoke-loading room door 4, two side walls 5 and The heating room partition wall 8 opposite to the smoke loading room door 4, the partition wall 8 has an air supply port 9 connecting the smoke loading room 1 and the heating room 2 above, and has an air return port 10 connecting the smoke loading room 1 and the heating room 2 below; The bottom of the flue-curing room has a bottom plate 6 and the top has a top plate 7.

[0040] It also includes a frame, which includes a hoisting support frame, a wall encapsulation structure, an overall frame of a smoke beam and smoke rack, an overall frame of a heating room and a heat pump fixing structure.

[0041]The hoisting supporting frame includes a main frame 11 around the bottom plate, a main frame 12 around ...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, a 30mm angle iron 18 is welded along the part of the peripheral main frame 11 of the bottom plate in the smoke chamber, which is used to lay the bottom plate 6 after laying the sealing filler. Figure 4 The lower half schematically shows the laid state of the base plate 6 .

[0047] like Figure 6 As shown, the peripheral main frame 11 of the bottom plate is connected with an auxiliary frame 19 for supporting and fixing the bottom plate. The auxiliary frame 19 includes two hot-dip galvanized square tubes with a length equal to the side wall arranged parallel to the side wall, and a length not less than Intermediate hot-dip galvanized square tubes 20 for half the length of the side walls. The length of the middle hot-dip galvanized square pipe 20 is 3.1 meters, and the auxiliary frame adopts a hot-dip galvanized square pipe of 50*50*2.5mm. The heat pump fixing structure also inclu...

Embodiment 3

[0049] The difference between this embodiment and the preceding embodiments is that, as Figure 7 As shown, the top board 7 includes three wall panels, which are respectively connected by buckles 21, as Figure 7 As shown, the hasp 21 is that part of the surface of one of the two adjacent top and wall panels protrudes outward, and the corresponding surface is recessed inward, forming a hasp structure. The surface of the recessed portion below the hasp 21 has a groove 22 filled with sealing and insulating material. The buckles 21 are respectively located at positions corresponding to the top beam 27 and the partition wall 8 .

[0050] like Figure 8 As shown, the plastic rainproof and waterproof tile 35 is installed on the top plate, and four vertical beams at the four corners are welded with lifting lugs.

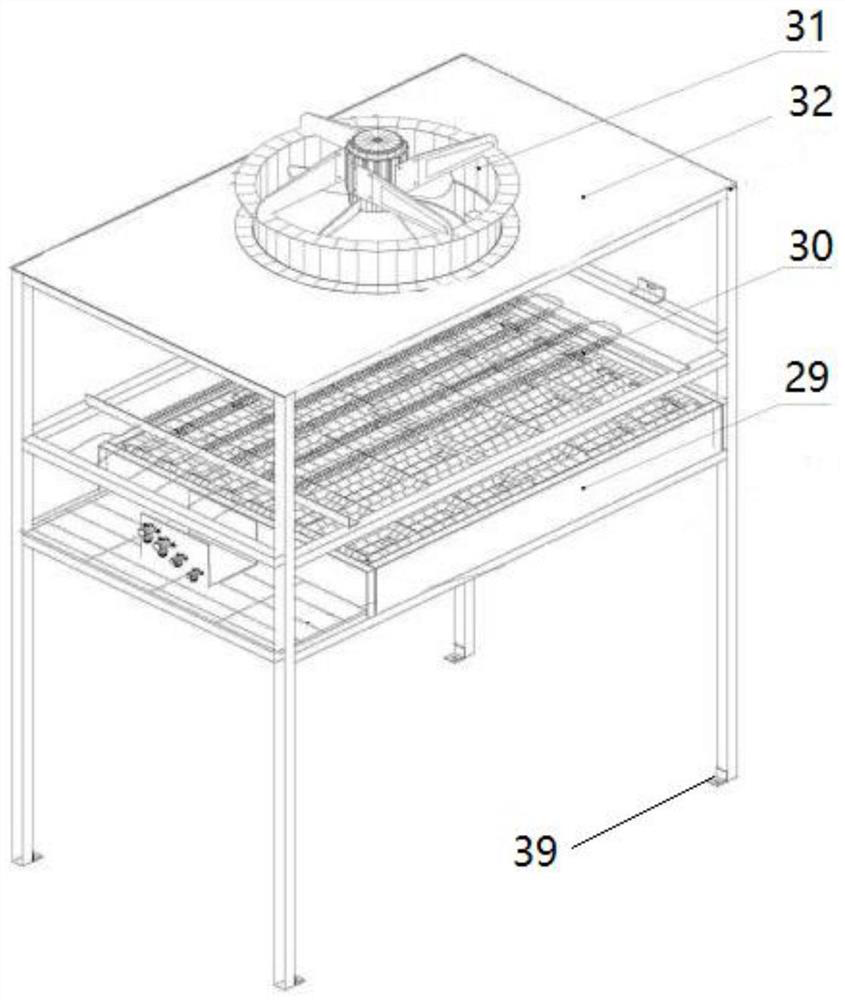

[0051] like Figure 9 As shown, a reinforcing beam 37 is added between the two heat pump base support vertical beams 14 above the heat pump 36 . An inspection door 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com