Filter screen structure convenient to disassemble and assemble for atmospheric pollution control purification device

A purification device and filter screen technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, etc. It can solve the problems of inability to quickly disassemble, waste time, inconvenient filter cleaning and maintenance, lack of sterilization and odor removal To improve the convenience and practicability of disassembly and assembly, the installation limit effect is stable and firm, and the effect of avoiding cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

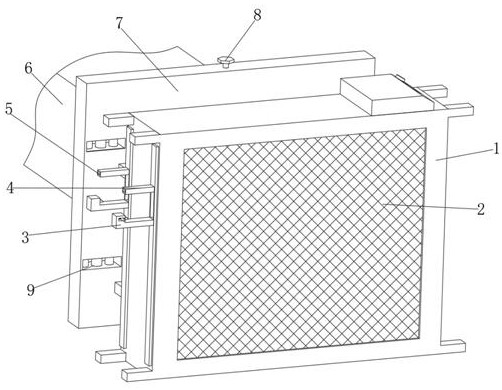

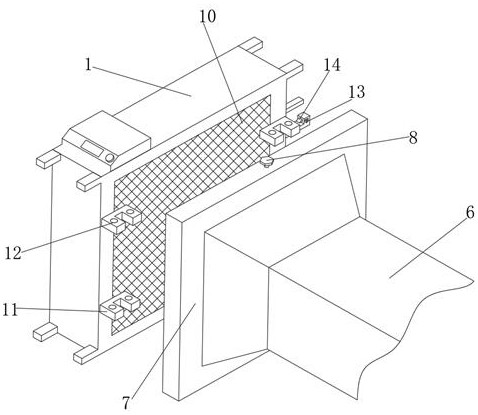

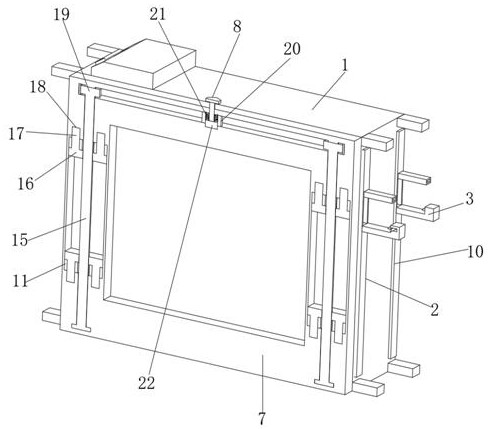

[0023] see Figure 1-Figure 6 , the present invention provides the following technical solutions: a filter screen structure for an air pollution control and purification device that is easy to disassemble, including a shell 1, a first filter screen 2 is installed inside the shell 1, and one end surface of the first filter screen 2 is fixedly connected There is a fixed handle 3, the inside of the first filter screen 2 is slidably connected with a slide bar 4, the front end of the slide bar 4 is provided with a limit groove 5 that is engaged with a limit block 14, and one side of the shell 1 is provided with an exhaust gas pipe 6 , the front end of the waste gas pipeline 6 is provided with a fixed plate 7, the inside of the fixed plate 7 is rotatably connected with a rotating rod 8, the surface of the fixed plate 7 is provided with a card slot 9 that is engaged with the card plate 11, and the inner side of the housing 1 is provided There is a second filter screen 10. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com