Rapid assembly production line for hydraulic hose connectors

A technology for assembling production lines and hydraulic hoses, used in assembly machines, decorative arts, cleaning methods using liquids, etc., can solve the problems of difficult discharge, time-consuming and laborious, shallow rolling marks, etc. the effect of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

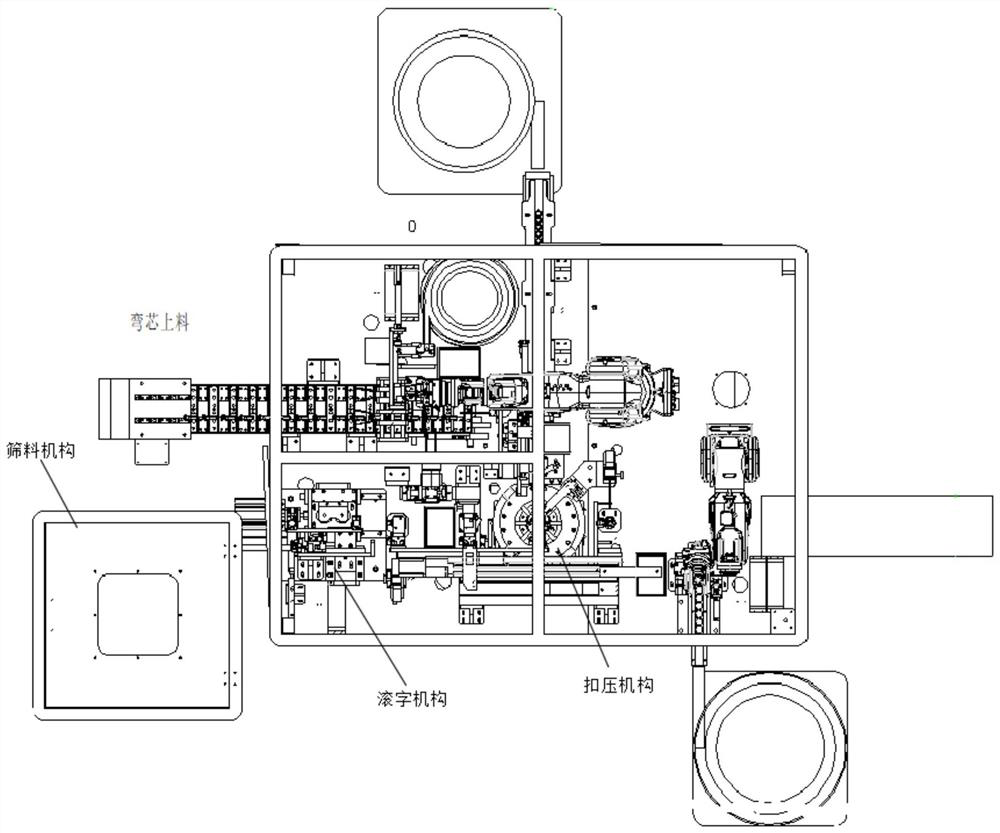

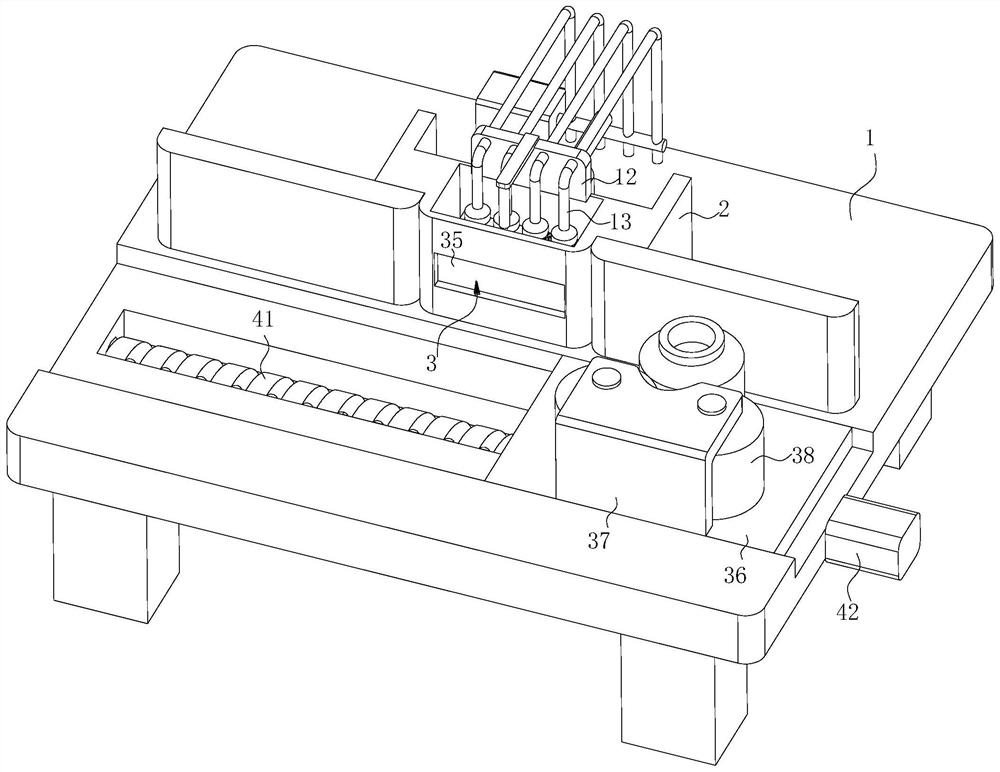

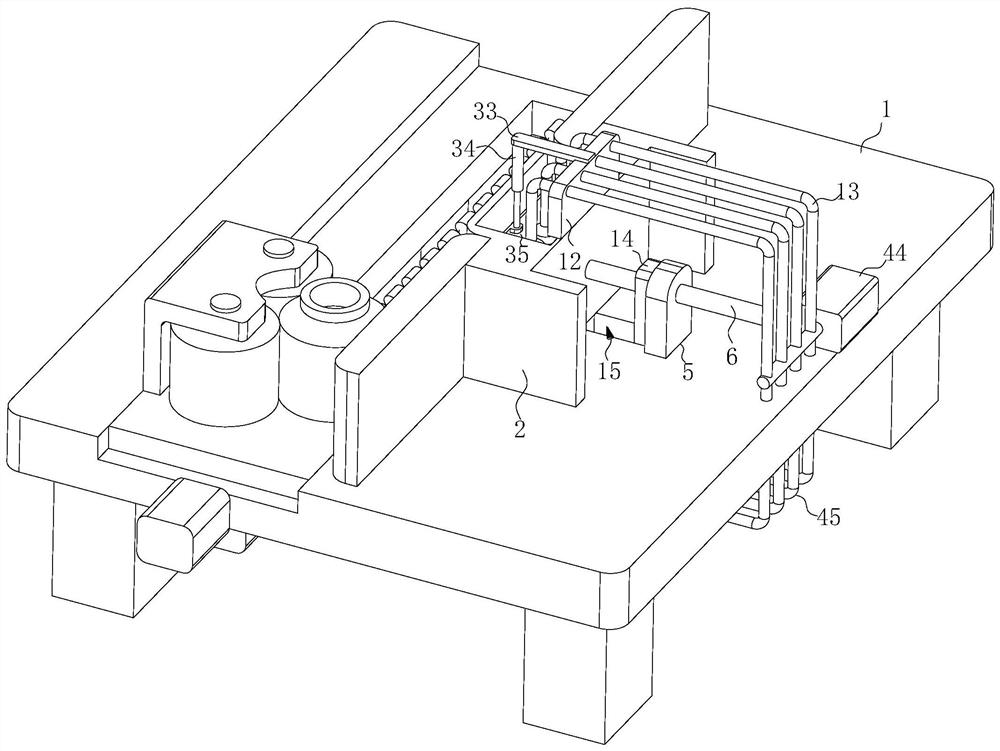

[0031] see Figure 1-11, the present invention provides a technical solution: a rapid assembly line for hydraulic hose joints, including a screening mechanism, a character rolling mechanism, and a crimping mechanism. character, the character rolling mechanism is located between the screening mechanism and the crimping mechanism, wherein the character rolling mechanism includes a support base 1, the top of the support base 1 is connected with a storage mechanism for driving the sleeve to move laterally, and the top of the support base 1 is fixedly connected with a fixed seat 2 , the inside of the fixed seat 2 is provided with a rolling mouth 3, the inside of the fixed seat 2 is provided with a mounting plate 4, the mounting plate 4 is used to install the rolling font, and the internal connection of the fixed seat 2 is used to make the mounting plate 4 move back and forth and turn over for cleaning. cleaning agencies;

[0032] The cleaning mechanism includes a first fixed plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap