Carrying device with intelligent balance weight adjusting function and using method

A handling device and intelligent adjustment technology, which is applied in the direction of storage device, transportation and packaging, etc., can solve the problems of unbalanced force on the structure of the trolley, lack of center of gravity of the goods, and influence on the service life of the trolley, so as to achieve good flexibility of the device and wide range of use wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

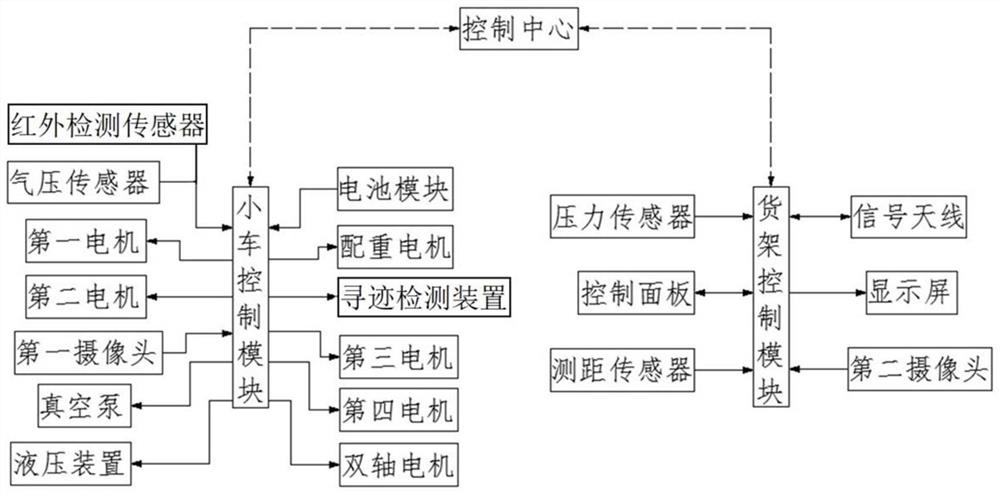

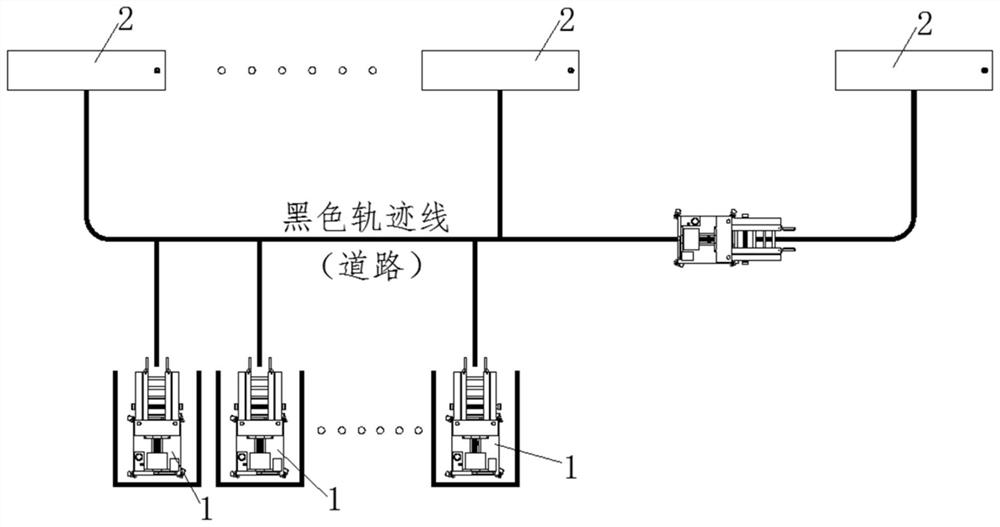

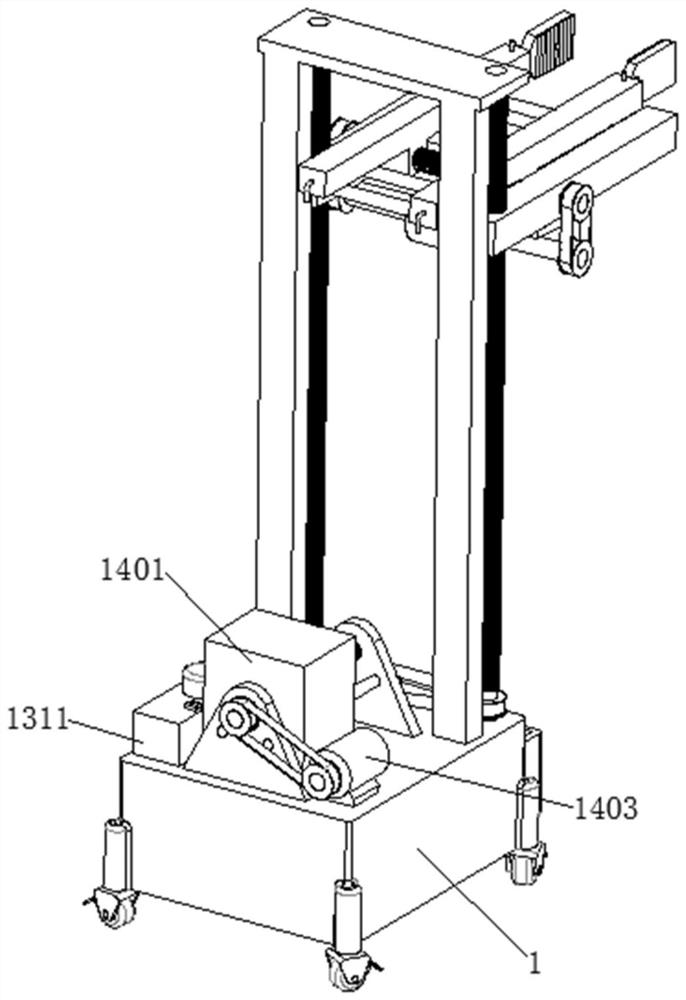

[0063] Embodiment 1. A handling device with intelligent adjustment of counterweight, such as Figure 1-12 As shown, it includes a plurality of smart cars 1, a plurality of smart shelves 2 and a control center. The smart cars 1 and the smart shelves 2 are respectively connected to the control center through a wireless network. The position side is used to store the workpieces produced by each process. Each smart car 1 is located between the fixed standby position and each smart shelf 2, and the road surface between each smart shelf 2 is provided with a black "trajectory line" as a predetermined When working, the smart car 1 travels between each smart shelf 2 according to the predetermined tracing line and carries goods (workpieces produced by each station of the assembly line); when it is in standby, the smart car 1 stops at a fixed stand The location charges itself and waits for a handling command from the control center.

[0064] The smart car 1 includes a driving device, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com