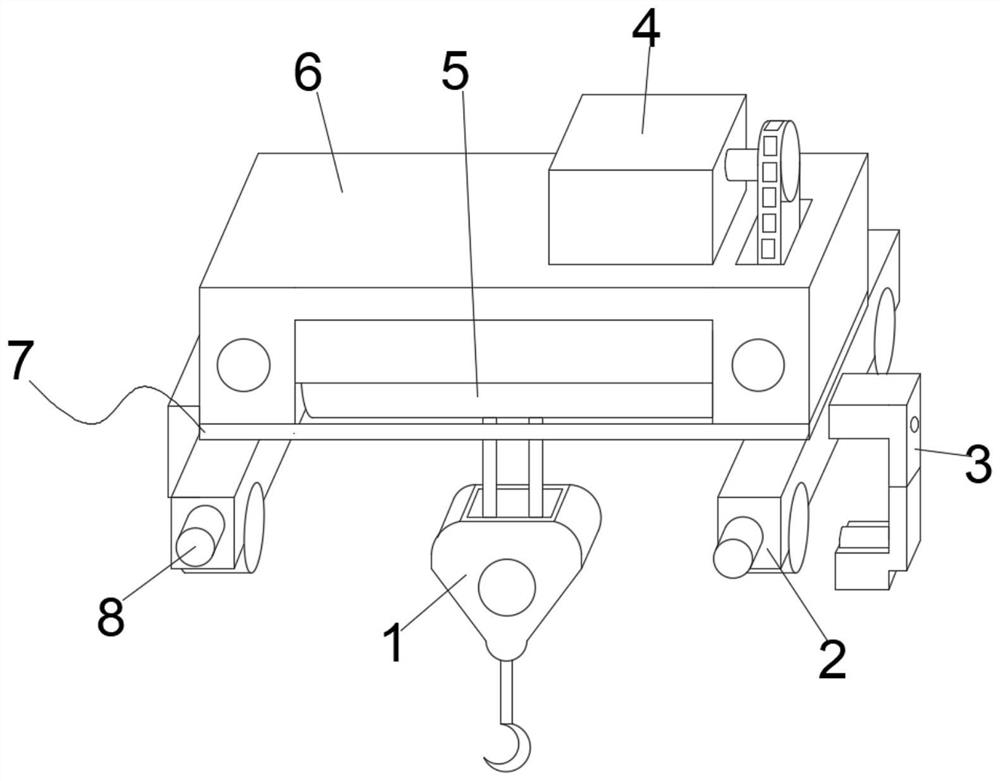

Mobile trolley with buffer mechanism for European style crane

A technology of buffer mechanism and mobile trolley, which is applied in the direction of traveling mechanism, load block, mechanical equipment, etc., can solve the problems of reducing the scope of application, not having an installation adjustment structure, not having a buffer protection structure, etc., and achieves the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

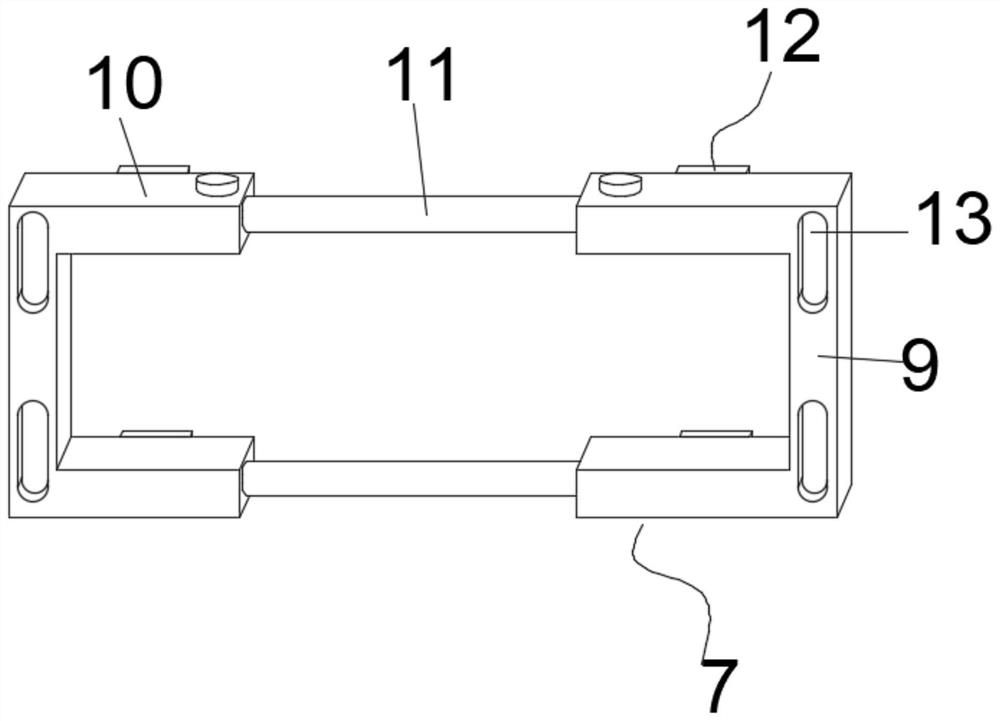

[0035] The combined frame 7 includes a first card frame 9 and a second card frame 10, which are flexibly connected by two sets of telescopic columns 11. When the combined frame 7 is in use, the user can The size of the base 2 and the sealing cover 6 pulls the first card frame 9 and the second card frame 10 of the combination frame 7, so that the telescopic column 11 is drawn out from between the first card frame 9 and the second card frame 10, thereby adjusting the combination The use size of frame 7.

[0036] The inner sides of the first card frame 9 and the second card frame 10 are all provided with cylindrical grooves for installing the telescopic column 11, and the sides of the first card frame 9 and the second card frame 10 are equipped with locking and fixed telescopic slots. The bolts of the column 11, when the telescopic column 11 is used, utilize the setting of the columnar groove pair to make the telescopic column 11 play the role of telescopic adjustment, and after ...

Embodiment 2

[0039] The outer surfaces of the first card frame 9 and the second card frame 10 are provided with two sets of waist-shaped notches 13 for fixing the mobile base 2 with gaskets. By using the settings of the waist-shaped notches 13, the gaskets can be matched by bolts. It plays a fixed role in the installation of the first card frame 9 and the second card frame 10, and its installation position can be adjusted appropriately through the structure of the waist-shaped notch 13 itself.

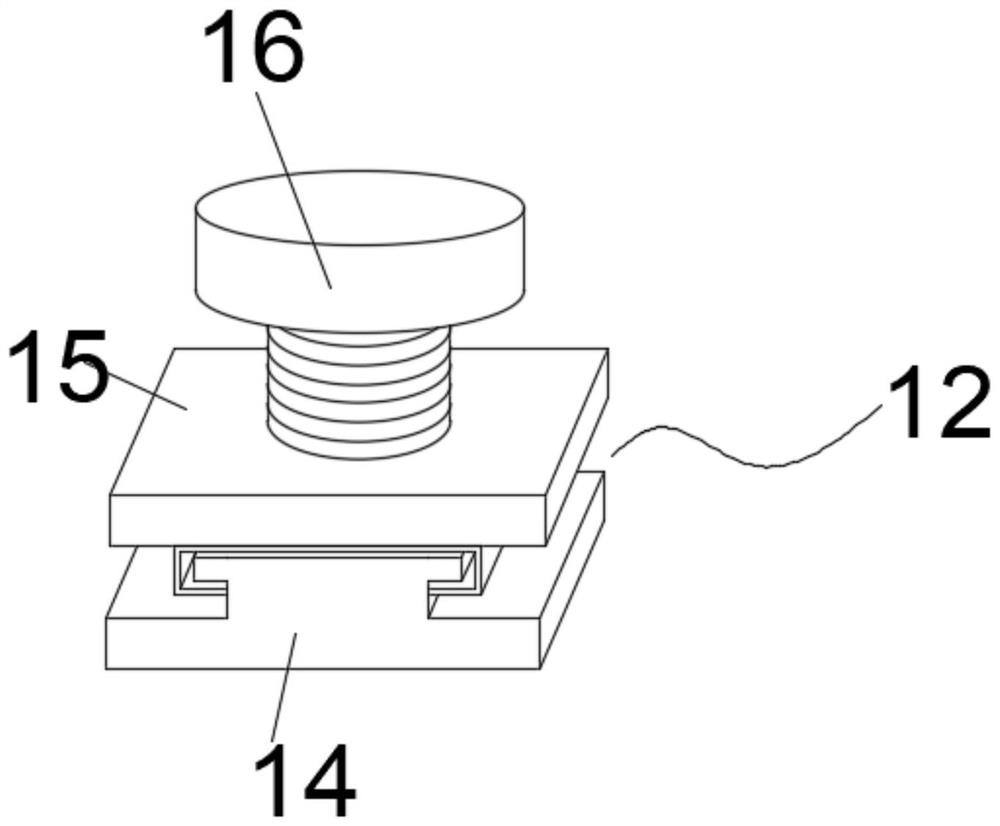

[0040] The sliding fixture 12 includes a lower clamping plate 14 and an upper clamping plate 15, the upper clamping plate 15 is movably installed on the top of the lower clamping plate 14, the lower clamping plate 14 and the upper clamping plate 15 are butted through a draw-in groove, and the middle part of the lower clamping plate 14 and the upper clamping plate 15 is sleeved with a tight The fastening bolt 16, when the sliding clamp 12 is used, by inserting the fastening bolt 16, the lower clampin...

Embodiment 3

[0042] One end of the buffer column 8 is movably socketed with a fixed block 23, and a spring 17 is installed inside the fixed block 23, and the middle part of one end of the fixed block 23 is movably socketed with a threaded sleeve rod 18. When the buffer column 8 is in use, the user The spring 17 can be squeezed by rotating one end of the threaded sleeve rod 18, thereby adjusting the softness and hardness of the spring 17. When the buffer post 8 hits, the spring 17 can play an elastic buffering effect on the buffer post 8.

[0043] One side of the auxiliary tripod 3 is provided with a telescopic block 21, and the auxiliary tripod 3 and the mobile base 2 are flexibly connected by the telescopic block 21. When the auxiliary tripod 3 is in use, the installation of the auxiliary tripod 3 can be adjusted by using the telescopic block 21. Position, so that the auxiliary tripod 3 can be adjusted according to the position of the beam of the European crane. At the same time, after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com