Preparation method of hemp colored stone paint

The technology of stone paint and hemp color is applied in the field of preparation of hemp color stone paint, which can solve the problems of poor quality of real stone paint, increased waste of resources, poor covering power, poor weather resistance and sand loss, etc., and achieves strong pollution resistance and structural Dense, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

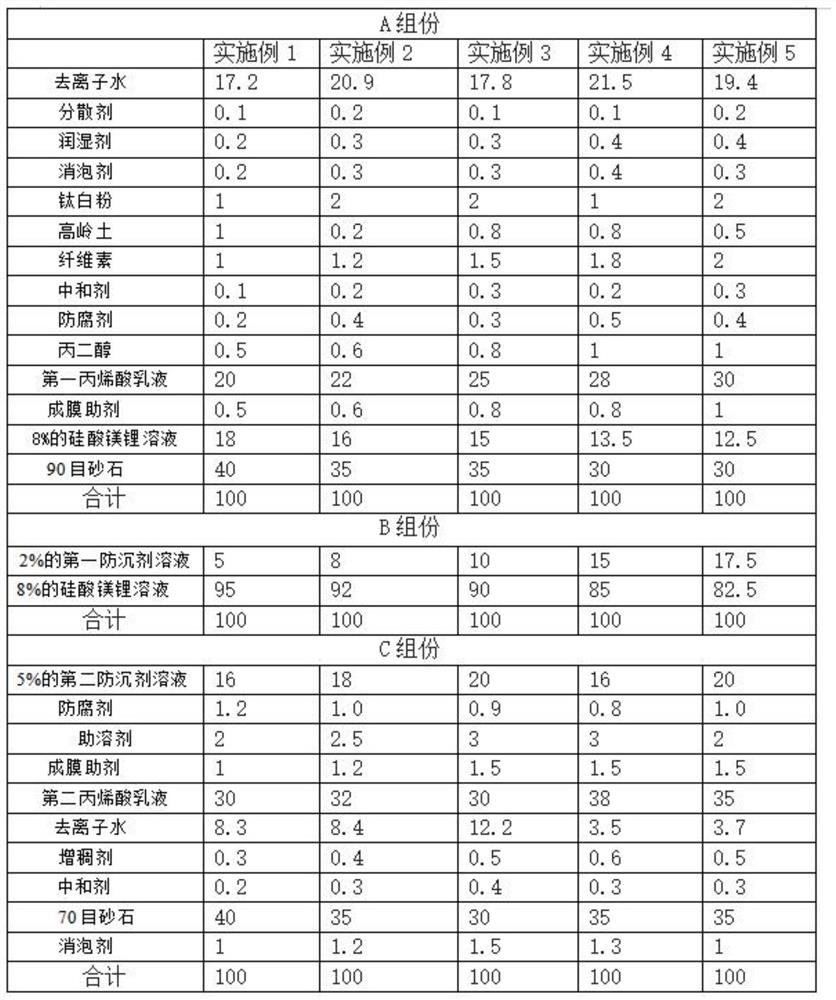

[0021] The invention provides a kind of preparation method of hemp colored stone paint, comprises the following steps:

[0022] Preparation of component A: add deionized water, dispersant, wetting agent and defoamer to the production tank and mix together, stir at 400-600 rpm for 2 minutes; slowly add titanium dioxide, Stir kaolin and cellulose at a speed of 600-800 rpm for 20-30 minutes, sample and test the diameter of the particles in the solution until the diameter is less than 50 microns; slowly add neutralizer, preservative and propylene glycol while stirring , continue to stir for 5 minutes; while stirring, slowly add the first acrylic acid emulsion and film-forming aid, and continue to stir for 10-20 minutes; Stir at a speed of rev / min for 5-10 minutes; slowly add 90-mesh gravel while stirring, and stir at a speed of 400-500 rev / min for 10-20 minutes.

[0023] Preparation of component B: uniformly mix the first anti-settling agent solution with a concentration of 2% an...

Embodiment 1

[0035] In this example, the proportion of each substance in component A is: deionized water 17.2%, dispersant 0.1%, wetting agent 0.2%, defoamer 0.2%, titanium dioxide 1%, kaolin 1%, cellulose 1%, 0.1% neutralizer, 0.2% preservative, 0.5% propylene glycol, 20% first acrylic emulsion, 0.5% film-forming aid, 18% lithium magnesium silicate solution with a concentration of 8%, 40 90 mesh sandstone %.

[0036] The proportion of each substance in component B is: 5% of the first anti-settling agent solution with a concentration of 2%, and 95% of a lithium magnesium silicate solution with a concentration of 8%.

[0037] The proportion of each substance in component C is: 16% of the second anti-settling agent with a concentration of 5%, 1.2% of preservative, 2% of co-solvent, 1% of film-forming aid, 30% of the second acrylic emulsion, 8.3% ionized water, 0.3% compound thickener, 0.2% neutralizer, 40% 70 mesh sandstone, 1% defoamer.

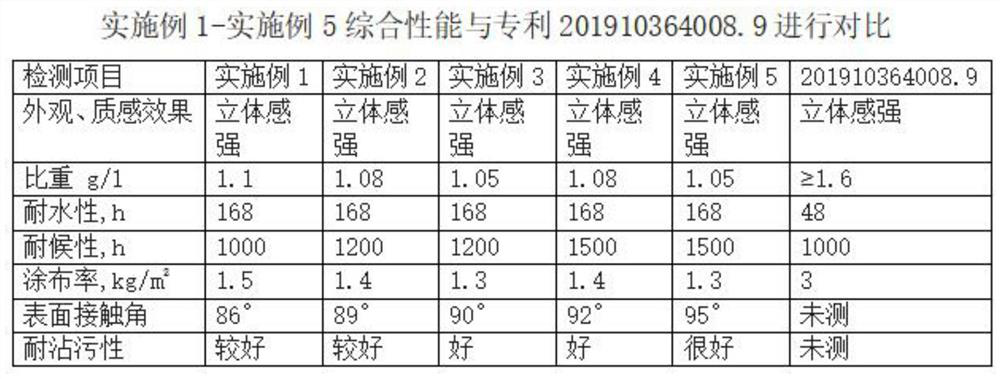

[0038] The appearance texture of the hemp colored ...

Embodiment 2

[0040] In this example, the proportion of each substance in component A is: deionized water 20.9%, dispersant 0.2%, wetting agent 0.3%, defoamer 0.3%, titanium dioxide 2%, kaolin 0.2%, cellulose 1.2%, 0.2% neutralizer, 0.4% preservative, 0.6% propylene glycol, 22% first acrylic emulsion, 0.6% film-forming aid, 16% lithium magnesium silicate solution with a concentration of 8%, 35% of 90 mesh sandstone %.

[0041] The proportion of each substance in component B is: 8% of the first anti-settling agent solution with a concentration of 2%, and 92% of a lithium magnesium silicate solution with a concentration of 8%.

[0042] The proportion of each substance in component C is: 18% of the second anti-settling agent with a concentration of 5%, 1% of preservative, 2.5% of co-solvent, 1.2% of film-forming aid, 32% of the second acrylic emulsion, 8.4% ionized water, 0.4% compound thickener, 0.3% neutralizer, 35% 70-mesh sandstone, and 1.2% defoamer.

[0043] The appearance texture of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap