Waterborne epoxy zinc-rich primer as well as preparation method and application thereof

A water-based epoxy zinc-rich and primer technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as damage to the health of construction workers, flammable and explosive risks of solvents, and serious environmental pollution. To achieve the effect of fast drying, low reactivity and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

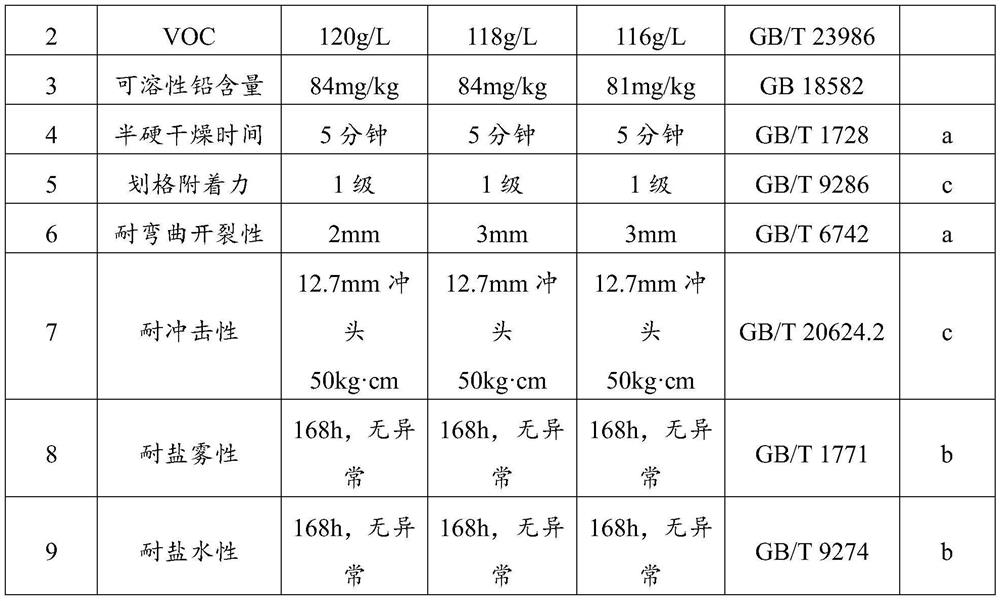

Embodiment 1

[0033] This embodiment is used for the waterborne epoxy zinc-rich primer of container pretreatment, wherein, A component (weight): modified bisphenol A type epoxy resin emulsion 199kg and defoamer 1kg, modified bisphenol A type ring The oxygen resin emulsion can be H-502-42W from DIC Company and BYK-024 from BYK Company as the defoamer.

[0034] Add the modified bisphenol A type epoxy resin emulsion and defoamer in proportion, stir at 400-600rpm for 10-15 minutes and mix evenly to prepare component A.

[0035] Component B (weight): water-soluble modified amine curing agent 200kg, dispersant 30kg, film-forming aid 18kg, fumed silica 13.5kg, talcum powder 50kg, zinc powder 1350kg, zinc powder protective agent 15kg and anti-settling agent 12kg.

[0036] The water-soluble modified amine curing agent adopts the propylene glycol methyl ether solution (NX-8106PM80 of Cardolite) of the cardanol modified amine curing agent with a solid content of 80%; Polymer block copolymer dispersa...

Embodiment 2

[0040] The present embodiment is used for the waterborne epoxy zinc-rich primer of container pretreatment, wherein, A component (weight): modified bisphenol A type epoxy resin emulsion 196kg and defoamer 4kg, modified bisphenol A type ring The oxygen resin emulsion can be H-502-42W from DIC Company and BYK-024 from BYK Company as the defoamer.

[0041] Add the modified bisphenol A type epoxy resin emulsion and defoamer in proportion, stir at 400-600rpm for 10-15 minutes and mix evenly to prepare component A.

[0042] Component B (weight): water-soluble modified amine curing agent 180kg, dispersant 40kg, film-forming aid 40kg, fumed silica 20kg, talcum powder 80kg, zinc powder 1600kg, zinc powder protective agent 20kg and anti-settling agent 20kg .

[0043]The water-soluble modified amine curing agent adopts the propylene glycol methyl ether solution (NX-8106PM80 of Cardolite) of the cardanol modified amine curing agent with a solid content of 80%; Polymer block copolymer dis...

Embodiment 3

[0047] The present embodiment is used for the waterborne epoxy zinc-rich primer of container pretreatment, wherein, A component (weight): modified bisphenol A type epoxy resin emulsion 198kg and defoamer 2kg, modified bisphenol A type ring The oxygen resin emulsion can be H-502-42W from DIC Company and BYK-024 from BYK Company as the defoamer.

[0048] Add the modified bisphenol A type epoxy resin emulsion and defoamer in proportion, stir at 400-600rpm for 10-15 minutes and mix evenly to prepare component A.

[0049] Component B (weight): 220kg water-soluble modified amine curing agent, 25kg dispersant, 30kg film-forming aid, 15kg fumed silica, 60kg talcum powder, 1550kg zinc powder, 15kg zinc powder protective agent and 15kg anti-sedimentation agent .

[0050] The water-soluble modified amine curing agent adopts the propylene glycol methyl ether solution (NX-8106PM80 of Cardolite) of the cardanol modified amine curing agent with a solid content of 80%; Polymer block copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com