Corrosion-resistant epoxy modified silicone-acrylic stone-like coating

A technology of epoxy modification and real stone paint, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor adhesion and chemical corrosion resistance, poor UV aging resistance, and difficult to control harmful gas emissions, so as to improve adhesion , good protection effect, superior environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

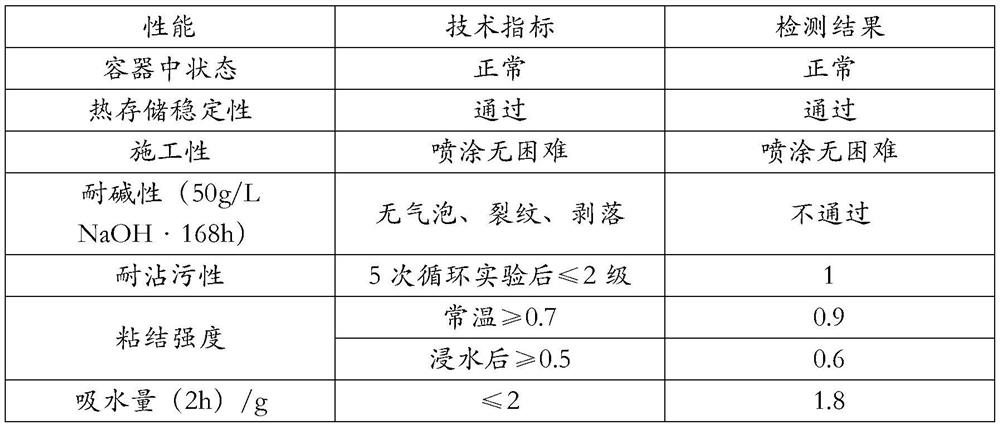

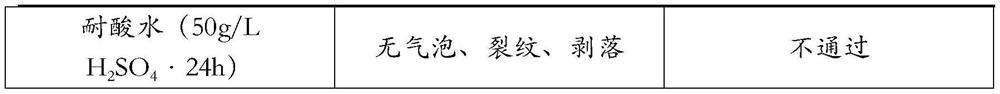

Examples

Embodiment 1

[0075] A corrosion-resistant epoxy modified silicon acrylic real stone paint, including the base material as the A component and the natural colored sand as the B component, according to the weight ratio, A component: B component = 25:75, wherein A group Made from the following raw materials:

[0076] Epoxy modified silicone acrylic emulsion: 46%

[0077] Water: 47.25%

[0078] Methyl cellulose ether: 0.7%

[0079] Modified inorganic bentonite: 0.15%

[0080] 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate: 2.7%

[0081] Ethylene glycol: 2.5%

[0082] 2-Amino-2-methyl-1-propanol: 0.3%

[0083] Isothiazolinones: 0.3%

[0084] Alkali-swellable thickener: 0.1%,

[0085] The above percentages are percentages by weight.

[0086] The preparation of corrosion-resistant epoxy modified silicon acrylic real stone paint comprises the following steps in the present embodiment:

[0087] Step S1: Add methyl cellulose ether and modified inorganic bentonite to water, disperse at high...

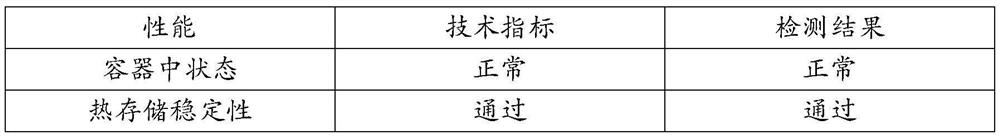

Embodiment 2

[0101] A corrosion-resistant epoxy modified silicon acrylic real stone paint, including the base material as the A component and the natural colored sand as the B component, according to the weight ratio, A component: B component = 25:75, wherein A group Made from the following raw materials:

[0102] Epoxy modified silicone acrylic emulsion: 47%

[0103] Water: 45.7%

[0104] Ethyl cellulose ether: 0.79%

[0105] Modified inorganic bentonite: 0.18%

[0106] 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate: 2.7%

[0107] Ethylene glycol: 2.8%

[0108] Ammonia: 0.36%

[0109] Isothiazolinones: 0.33%

[0110] Alkali-swellable thickener: 0.14%,

[0111] The above percentages are percentages by weight.

[0112] The preparation of corrosion-resistant epoxy modified silicon acrylic real stone paint comprises the following steps in the present embodiment:

[0113] Step S1: Add ethyl cellulose ether and modified inorganic bentonite to water, disperse until uniform at high spee...

Embodiment 3

[0120] A corrosion-resistant epoxy modified silicon acrylic real stone paint, including the base material as the A component and the natural colored sand as the B component, according to the weight ratio, A component: B component = 35:65, wherein A group Made from the following raw materials:

[0121] Epoxy modified silicone acrylic emulsion: 48%

[0122] Water: 44.75%

[0123] Hydroxymethyl Cellulose Ether: 0.75%

[0124] Modified inorganic bentonite: 0.17%

[0125] 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate: 2.8%

[0126] Ethylene glycol: 2.7%

[0127] 2-Amino-2-methyl-1-propanol: 0.35%

[0128] Imidazole derivatives: 0.35%

[0129] Alkali-swellable thickener: 0.13%,

[0130] The above percentages are percentages by weight.

[0131] The preparation of corrosion-resistant epoxy modified silicon acrylic real stone paint comprises the following steps in the present embodiment:

[0132] Step S1: Add hydroxymethyl cellulose ether and modified inorganic bentonite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com