Pavement joint cutting device for highway bridge construction and joint cutting method thereof

A technology for highway bridges and slitting, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of straight slitting of concrete pavements of highway bridges, bulky slitting devices, and affecting the quality of slitting construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

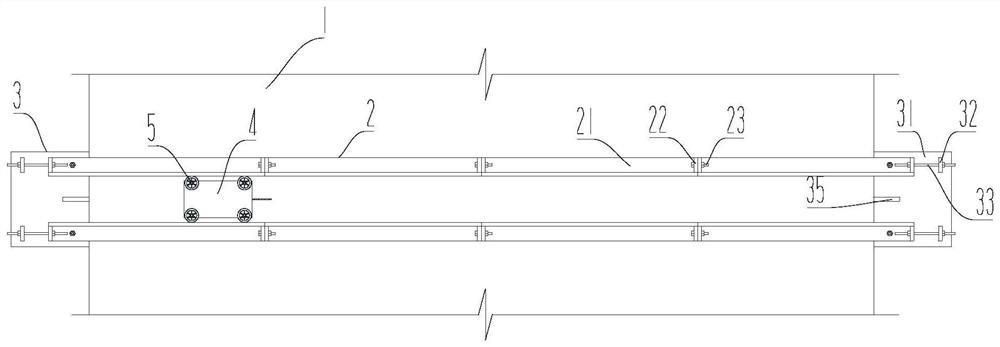

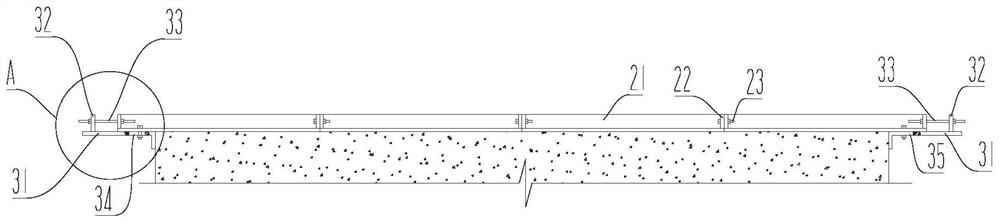

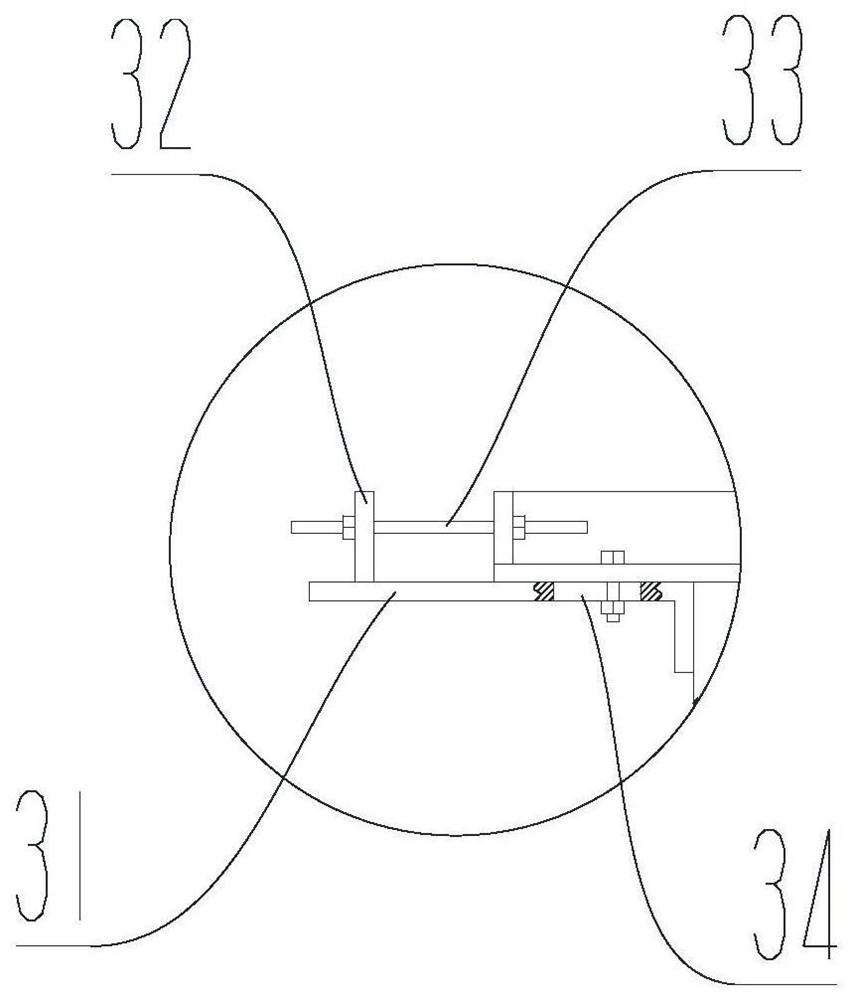

[0039] Please refer to Figure 1 ~ Figure 3 , figure 1 It is a top view of the slitting device according to the embodiment of the present invention; figure 2 It is the front view of the cutting device according to the embodiment of the present invention; image 3 for figure 2 Enlarged image at A.

[0040] A road surface cutting device for highway bridge construction, comprising two retaining rods 2 oppositely arranged on the road surface 1, the bottom surface of the retaining rods 2 is attached to the road surface 1, and a spacer is formed between the two oppositely disposed retaining rods 2. The guide groove that the seam cutter 4 walks, the guide groove carries out spacing and guidance to the walking direction of the seam cutter 4, ensures the precision of the seam cutter 4 walking, and guides it to cut out the vertical slit.

[0041] In the present invention, the model of the slitting machine 4 is not limited. In this embodiment, a chiniu road cutting machine is adop...

Embodiment 2

[0045] Please refer to Figure 1 ~ Figure 3 , figure 1 It is a top view of the slitting device according to the embodiment of the present invention; figure 2 It is the front view of the cutting device according to the embodiment of the present invention; image 3 for figure 2 Enlarged image at A.

[0046] This embodiment proposes a road surface cutting device for highway bridge construction, which has basically the same structure as that of Embodiment 1, and the similarities will not be repeated. Angle steel 21, detachable connection between any two adjacent angle steels 21.

[0047] In this embodiment, each retaining rod 2 is formed by successively connecting multiple angle steels 21, and the two adjacent angle steels 21 are detachably connected. It is connected as a whole, and when not in use, the retaining rod 2 is disassembled with multiple angle steels 21, so as to reduce the difficulty of carrying and placing the tools.

[0048] The angle steel 21 is an L-shaped ...

Embodiment 3

[0050] Please refer to Figure 1 ~ Figure 3 , figure 1 It is a top view of the slitting device according to the embodiment of the present invention; figure 2 It is the front view of the cutting device according to the embodiment of the present invention; image 3 for figure 2 Enlarged image at A.

[0051] This embodiment proposes a road surface cutting device for highway bridge construction, which is basically the same in structure as Embodiment 2, and the similarities will not be repeated. The difference is that the two ends of each angle steel 21 in this embodiment are A connecting plate 22 is provided, and the connecting plate 22 between two adjacent angle steels 21 is connected by bolts.

[0052] In this embodiment, the connecting plate 22 is welded to both ends of the angle iron 21, and the connecting plate 22 is vertically arranged relative to the angle iron. Because the baffle bar 2 adopts a segmental structure, the connecting plate 22 is used for connecting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com