Loader-digger capable of running in two directions

A backhoe loader, two-way driving technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of low operation efficiency, cumbersome operation of the two-way driving system, complicated transition, etc., to improve comfort and economy. , The effect of improving the efficiency of excavation operations and the compact structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

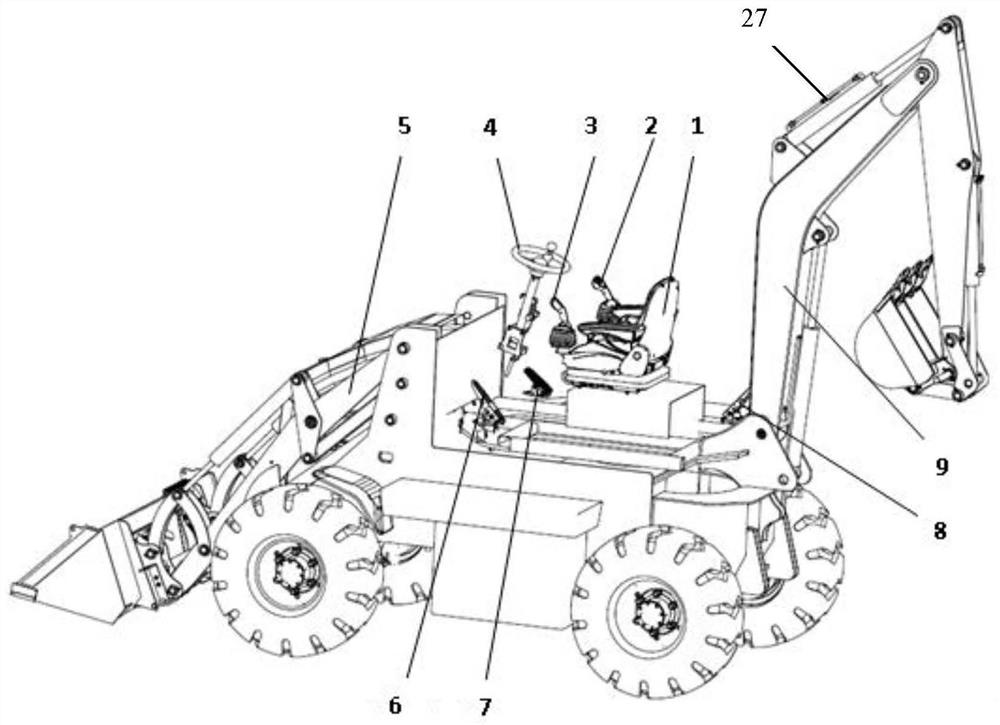

[0030] This embodiment discloses a backhoe loader traveling in two directions, such as figure 1 As shown, it includes 180° rotatable seat 1, control assembly A and control assembly B. The rotating seat 1 is equipped with a left joystick 3 and a right joystick 2, and the left joystick 3 and right joystick 2 can be carried out with the seat. Synchronized rotation. The loading end is provided with a loading device 5, and the excavating end is provided with an excavating device 9.

[0031] The control assembly A is located at the front loading end, including a steering wheel assembly 4 integrated with an electronically controlled shift handle, a foot accelerator 6, and a first brake mechanism 7, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com