A kind of base oil saturated vapor pressure blending method that can reduce methanol gasoline

A methanol gasoline and base oil technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve the problems of normal driving of vehicles, air resistance, saturated vapor pressure, etc., and achieves convenient and feasible application, simple formula and easy effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

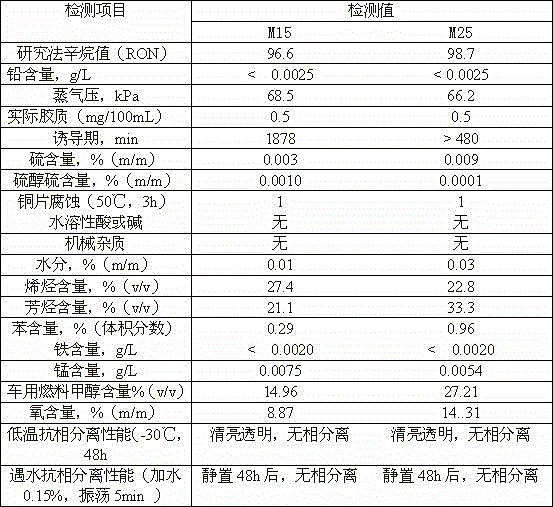

Embodiment 1

[0017] 10% solvent naphtha, 1% dimethyl carbonate, 5% reformed oil and 84% No. 93 gasoline. The above percentages are percentages by weight. The aromatic hydrocarbon content of the reformed oil is 25%-35%. Described solvent oil is 200# solvent oil.

[0018] Preparation:

[0019] The above-mentioned raw materials are prepared through a static mixer to form a low saturated vapor pressure base oil that can be used to prepare methanol gasoline.

[0020] Application: Put the following percentage by volume: 15% methanol, 3% methanol gasoline additive, and the above-mentioned 82% base oil in a container, mix well to make M15 methanol gasoline.

Embodiment 2

[0022] 12% solvent naphtha, 3% dimethyl carbonate, 7% reformed oil and 78% No. 93 national standard gasoline. The above percentages are percentages by weight. The aromatic hydrocarbon content of the reformed oil is 25%-35%. Described solvent oil is 200# solvent oil.

[0023] Preparation:

[0024] The above-mentioned raw materials are prepared through a static mixer to form a low saturated vapor pressure base oil that can be used to prepare methanol gasoline.

[0025] Application: Put the following percentage by volume: 15% methanol, 3% methanol gasoline additive, and the above-mentioned 82% base oil in a container, mix well to make M15 methanol gasoline.

Embodiment 3

[0027] 15% solvent naphtha, 5% dimethyl carbonate, 10% reformed oil and 70% No. 93 gasoline. The above percentages are percentages by weight. The aromatic hydrocarbon content of the reformed oil is 25%-35%. Described solvent oil is 200# solvent oil.

[0028] Preparation:

[0029] The above-mentioned raw materials are prepared through a static mixer to form a low saturated vapor pressure base oil that can be used to prepare methanol gasoline.

[0030] Application: Put the following percentages by volume: 25% methanol, 3% methanol gasoline additive, and the above-mentioned 72% base oil in a container, mix well to make M25 methanol gasoline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com