A hybrid gas condensing heat exchanger

A condensing heat exchanger, hybrid technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as increasing costs, reducing heat transfer efficiency of heat exchangers, reducing economical efficiency of heat exchangers, etc., to achieve Improve heat conversion efficiency, prolong the heat absorption path of water flow, and ensure the effect of heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

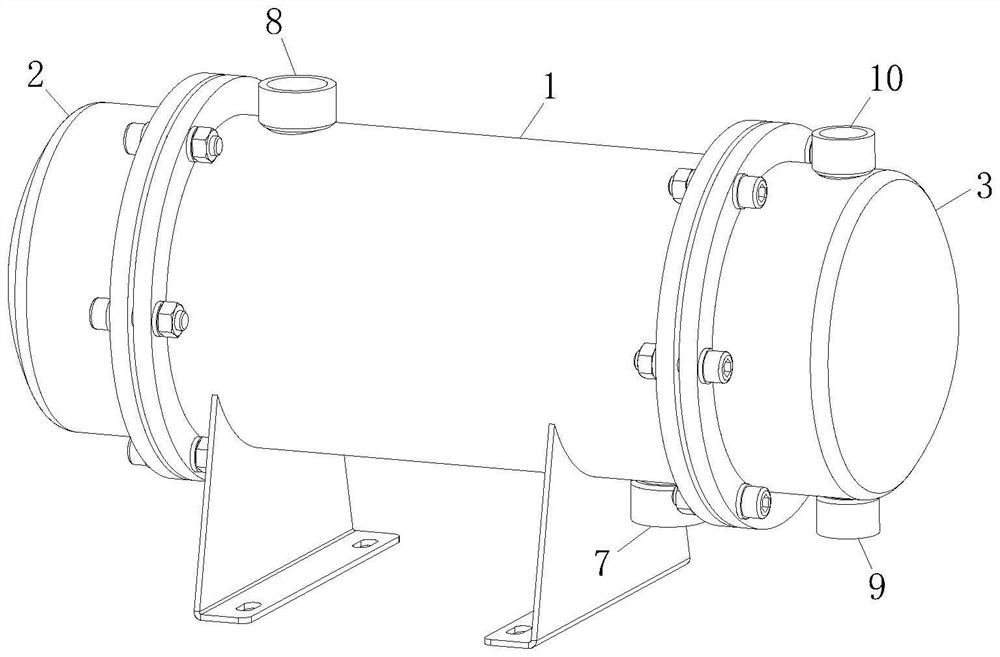

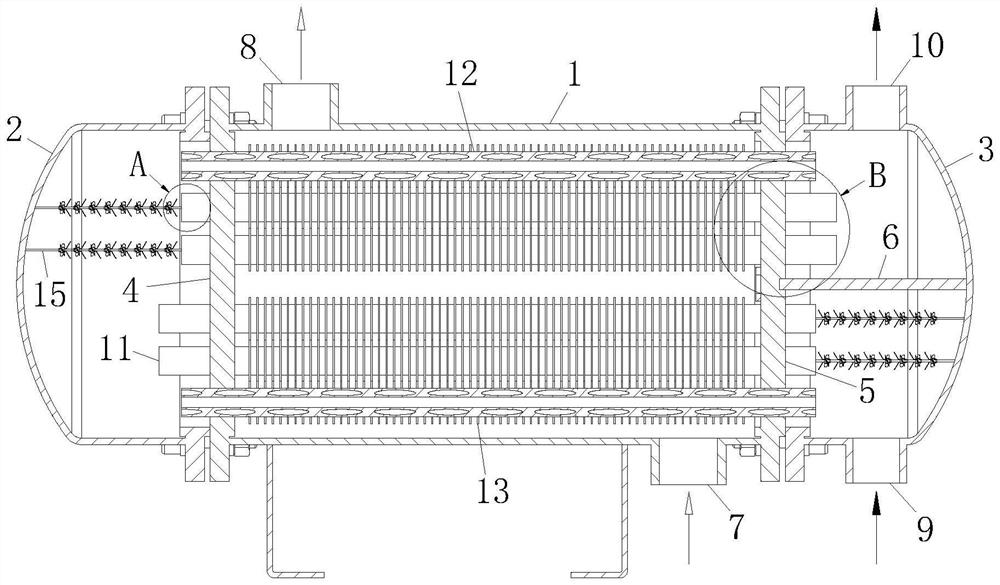

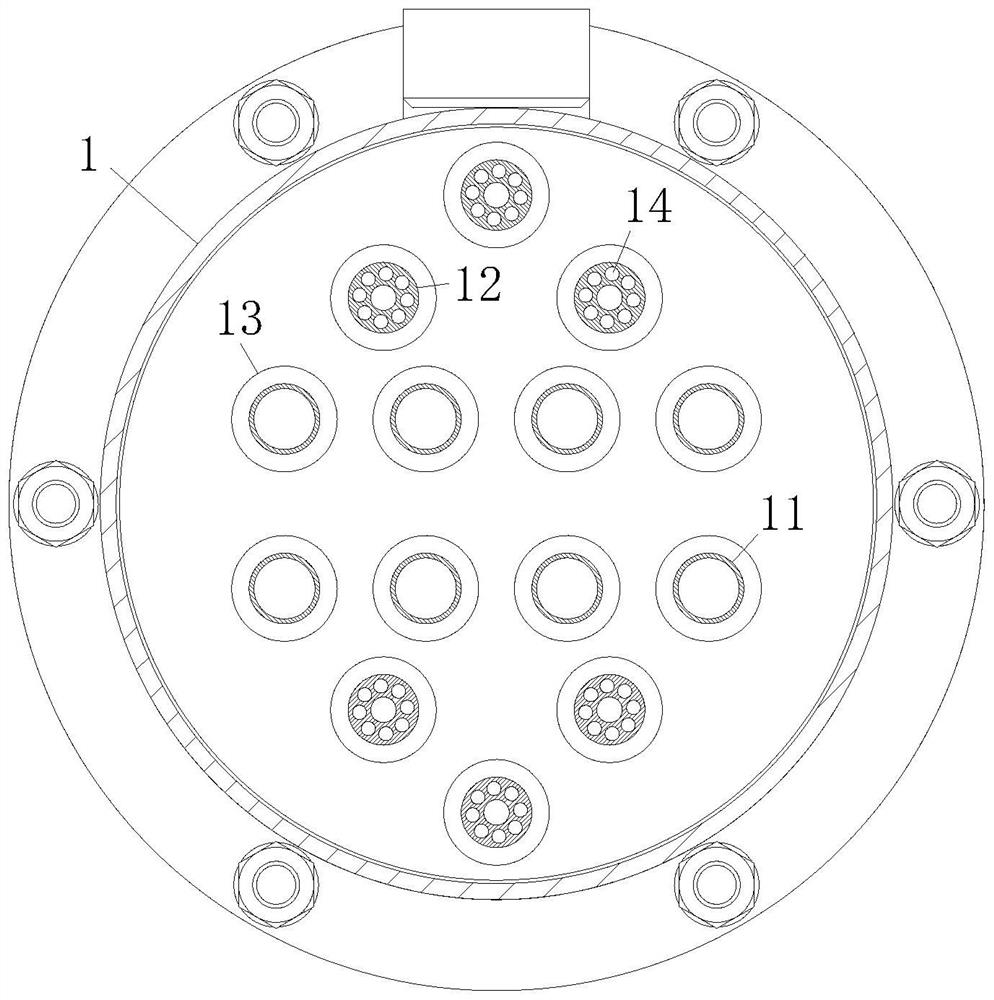

[0032] like Figure 1 to Figure 3 As shown, a hybrid gas-fired condensing heat exchanger according to an embodiment of the present invention includes a main casing 1; a left casing 2 and a right casing 3 are installed on both sides of the main casing 1; A left tube plate 4 is installed between the shell 1 and the left shell 2, and a right tube plate 5 is installed between the main shell 1 and the right shell 3; the right shell 3 is fixed with a partition plate 6; The main casing 1 is provided with an air inlet 7 and an air outlet 8; the right casing 3 is provided with a water inlet 9 and a water outlet 10; A straight heat pipe 11 and a plurality of spiral heat pipes 12, and the straight heat pipe 11 and the spiral heat pipe 12 communicate the left casing 2 with the right casing 3; A plurality of fins 13; the spiral heat pipe 12 is provided with a plurality of spiral holes 14; the high temperature flue gas enters the main casing 1 from the air inlet 7 at the bottom, and then f...

Embodiment 2

[0042] like Figure 8 As shown in the comparison example 1, another embodiment of the present invention is: an elastic film 34 is fixed between the No. 2 elastic sheet 33 and the inner wall of the installation pipe 28; the pipe wall of the installation pipe 28 is close to the elastic film 34 A guide hole 35 is opened at the position of the second magnet, and the guide hole 35 communicates with the elastic film 34; when the No. 2 magnetic block 23 squeezes the No. 2 elastic piece 33, the gas in the elastic film 34 inside will be ejected through the guide hole 35, It is sprayed on the surface of the fin 13 to blow off the condensed water adhering to the surface, which further improves the separation speed of the condensed water. After that, the No. 2 magnet block 23 is separated from the No. 2 spring piece 33, and the elastic film 34 is sucked through the guide hole 35. , this cycle.

[0043]Working principle: the high temperature flue gas enters the main casing 1 from the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com