Insulation platform used in screen cabinet and screen cabinet

A platform and insulating material technology, applied in electrical components, substation/distribution device casing, substation/switch layout details, etc., can solve problems such as difficulty in finding and taking out, short circuit, low maintenance efficiency, etc., to improve maintenance efficiency, Guarantee the effect of maintenance safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

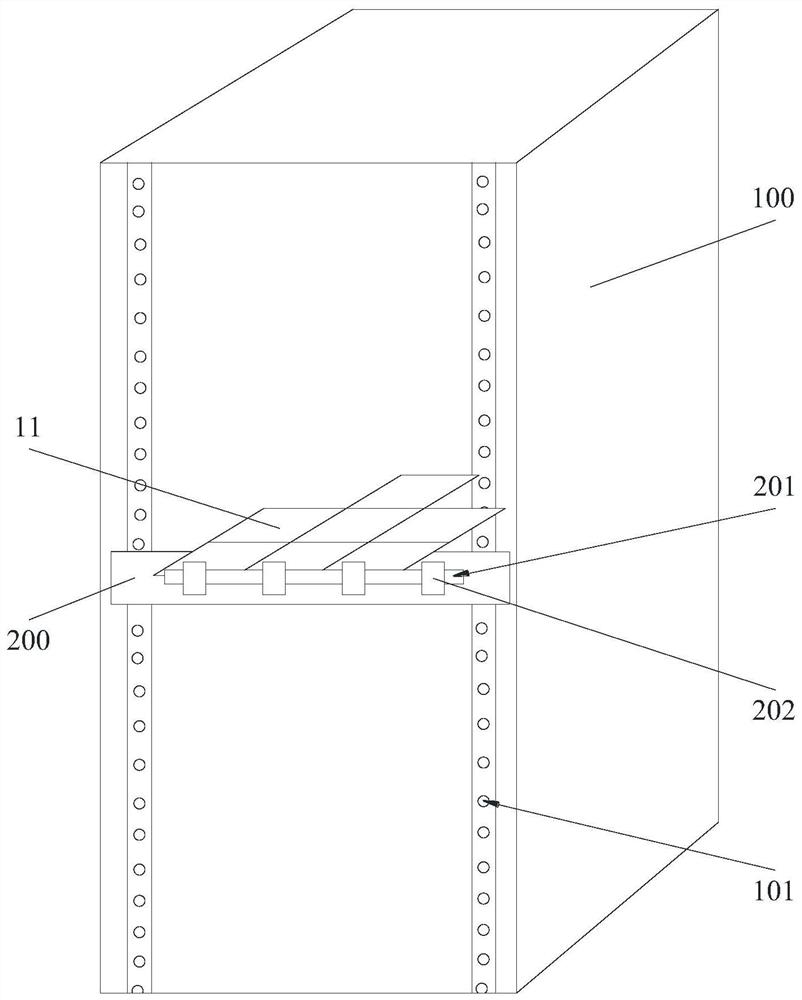

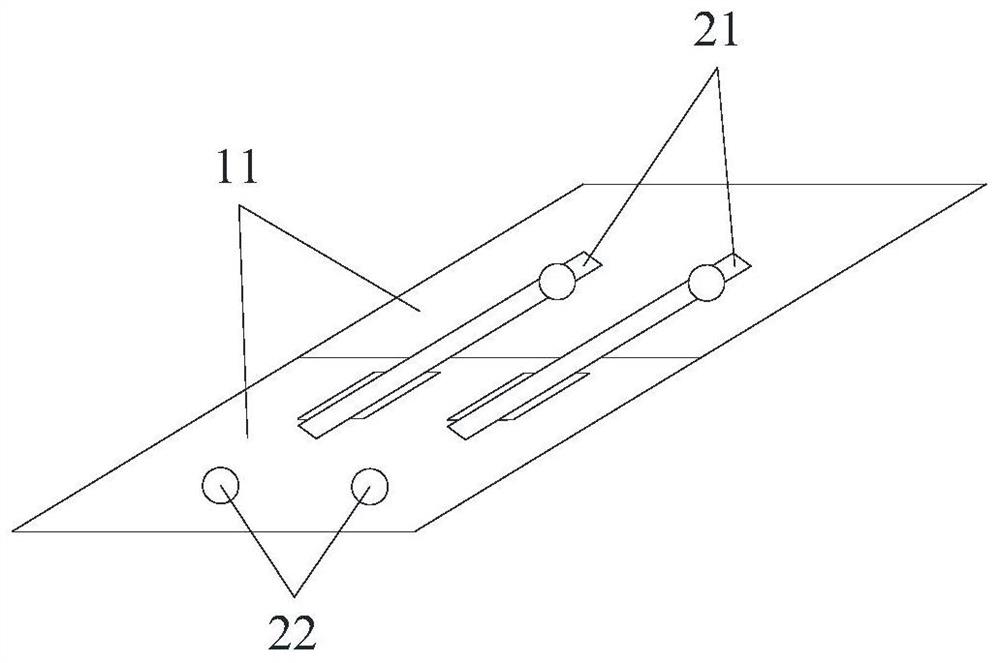

[0033] Such as figure 1 combine figure 2 As shown, this embodiment provides an insulating platform used in the screen cabinet. The insulating platform used in the screen cabinet is composed of a plurality of splicing parts, the splicing parts are made of insulating materials, and the splicing parts are composed of a bearing plate 11 and a surrounding It consists of a fixed fence outside the bearing plate 11, a pair of right-angled sides of the fixed fence are provided with tongues, and the other pair of right-angled sides are provided with slots matching the tongues, and the bottom of the bearing plate 11 is provided with a latch Assemblies, the latch rod 21 of the latch assembly can slide along the length direction of the bearing plate 11 to protrude out of the bearing plate 11 .

[0034] When in use, the modules that realize different functions can be placed on different bearing plates 11 respectively, and the adjacent bearing plates 11 are spliced together through the t...

Embodiment 2

[0048] Such as figure 1 combine figure 2 As shown, this embodiment provides a screen cabinet, including a cabinet body 100 and the insulation platform used in the screen cabinet in Embodiment 1, and the insulation platform used in the screen cabinet is detachably arranged in the cabinet body 100 .

[0049] Wherein, the screen cabinet further includes a support member 200, which is detachably arranged in the cabinet body 100, and the insulation platform used in the screen cabinet is detachably arranged on the support member 200 for easy replacement and disassembly.

[0050] In this embodiment, since the cabinet body 100 is provided with holes 101 for fixing wires, both ends of the support member 200 can be detachably connected to the cabinet body 100 through fasteners and holes 101 respectively.

[0051] Exemplarily, the support 200 is made of stainless steel externally bonded with thermosetting epoxy.

[0052] Furthermore, the length of the support member 200 is adjustable,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com