Novel quantitative dish distribution machine

A quantitative and vegetable-distributing technology, which is applied in cooking utensils, household utensils, applications, etc., can solve the problems of high cost and low efficiency of manual vegetable processing, so as to improve the efficiency of vegetable distribution, improve operating profits, and improve catering The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

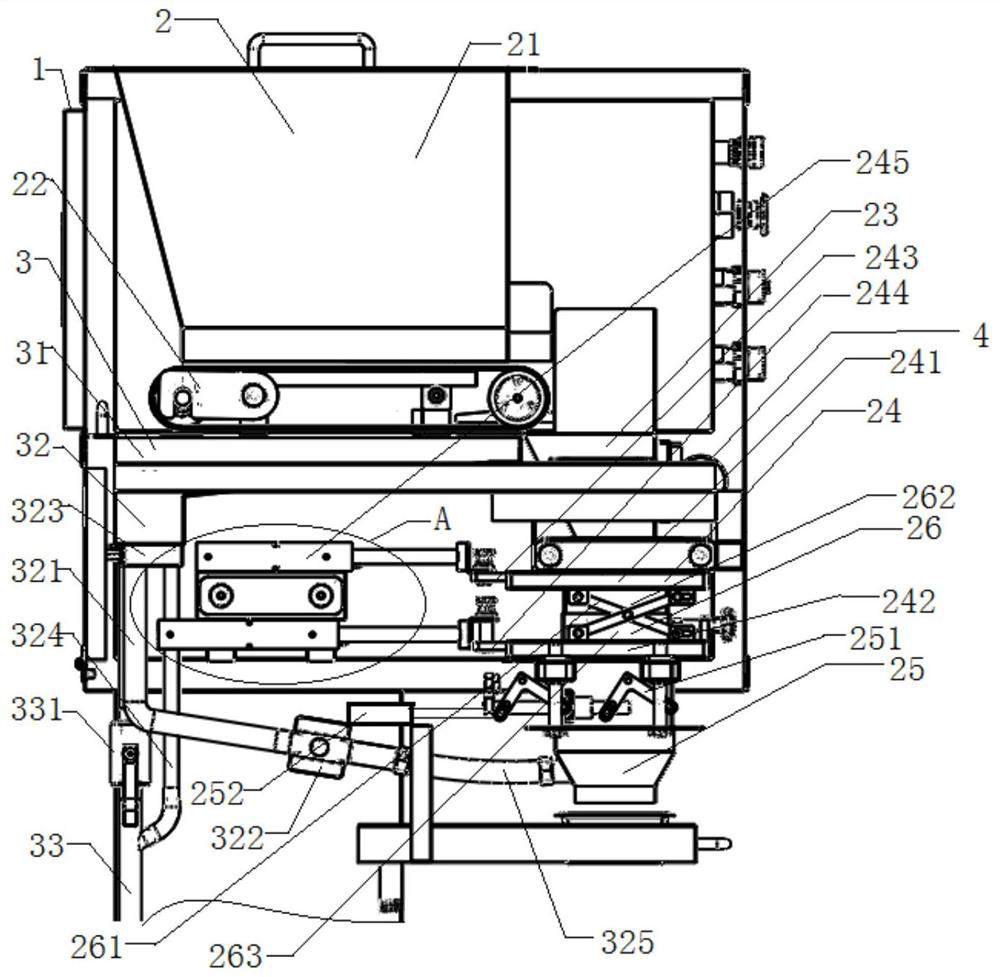

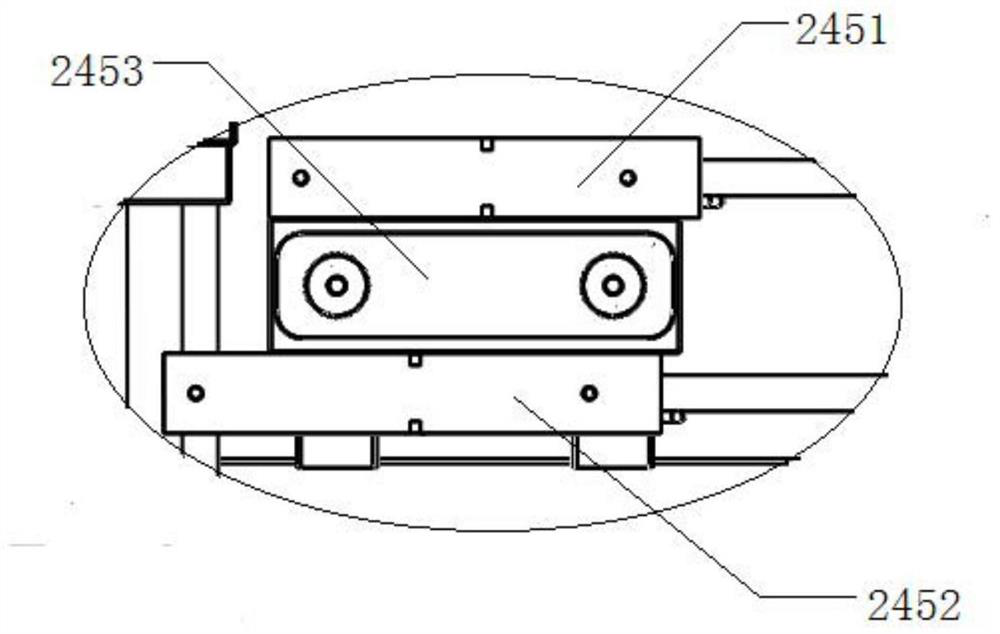

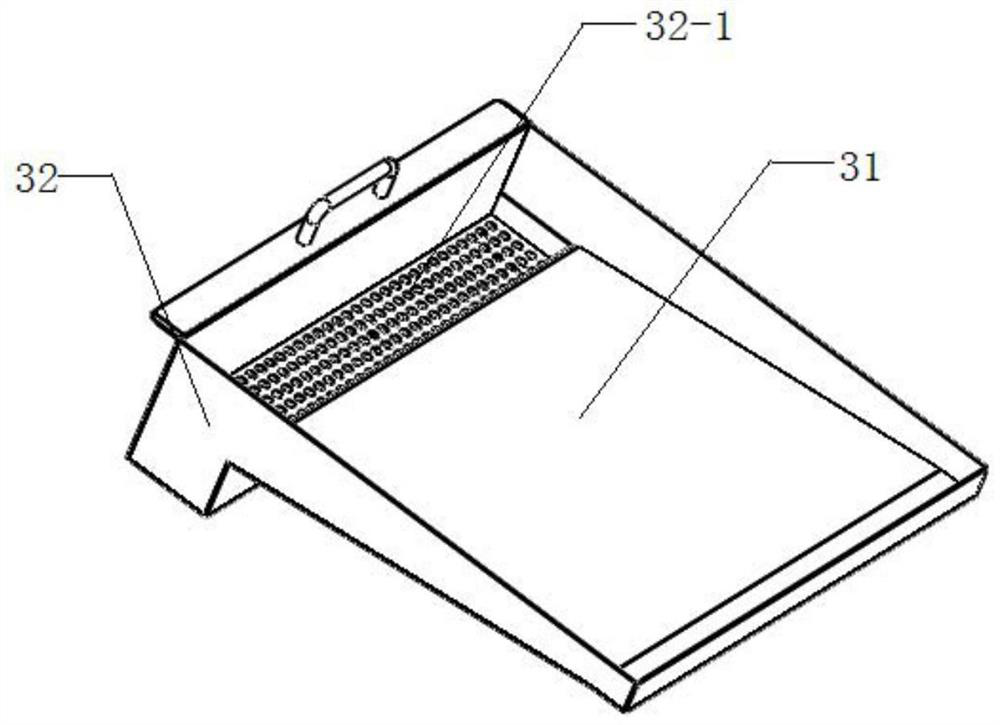

[0029] like Figure 1-9 As shown, a novel quantitative vegetable sorting machine includes a housing 1, a vegetable separating device 2, and a soup receiving device 3; Device 24, vegetable separation funnel 25, quantitative vegetable separation container 26, the top of the housing 1 is provided with a vegetable pouring funnel 25, and the bottom of the vegetable pouring funnel 25 is provided with a container that can separate dishes and soup and can transport cooked vegetable solids. Vegetable soup separation device 22, described vegetable soup separation device 22 is a conveyor, the bottom of vegetable soup separation device 22 is provided with a funnel 23 for serving vegetables, and the bottom of the funnel 23 for serving vegetables is provided with a dividing device 24, and the quantitative vegetable separation container 26 Installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com