Composite device of foamed aluminum multi-layer composite board and production process

A composite device and composite board technology, which is applied to the device and coating of the surface coating liquid, can solve the problems affecting the quality of the composite board, the frame and the board are not firmly bonded, etc., and achieve a simple and efficient structure. Enhance the effect of composite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

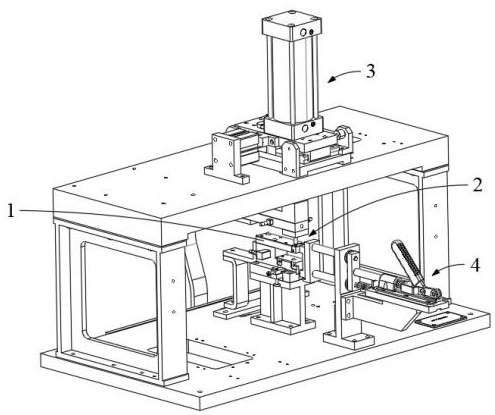

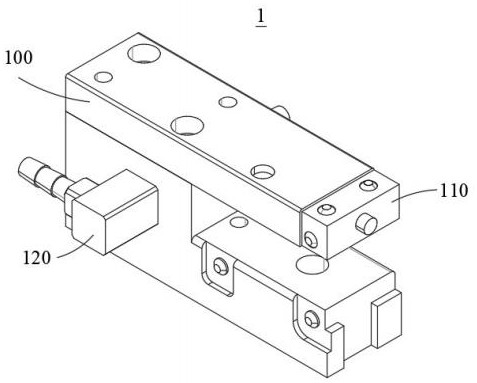

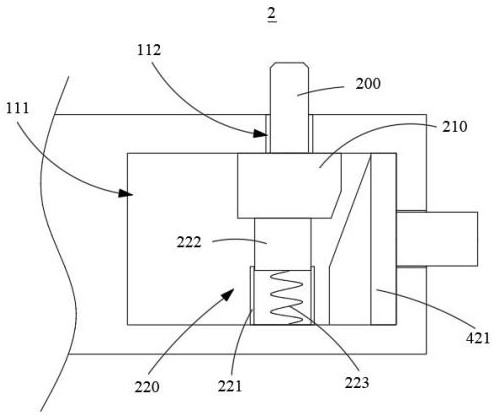

[0037] In this example, if Figure 1 to Figure 10 As shown, the present embodiment provides a composite device for aluminum foam multilayer composite panels, which includes: a panel placement platform 1, a glue dispensing mechanism 2, a glue injection mechanism 3 and a driving mechanism 4; wherein the panel placement platform 1 is suitable for The aluminum frame is placed on the shelf, and the plate placement platform 1 is provided with a support part 100 and a glue dispensing part 110; a number of glue storage chambers 111 are opened in the glue dispensing part 110, and the glue dispensing mechanism 2 is movably arranged on the corresponding In the glue storage chamber 111; the glue injection mechanism 3 is located above the glue dispensing mechanism 2, and the glue injection mechanism 3 presses down toward the glue dispensing mechanism 2 to enter the corresponding glue storage chamber 111, and injects into the glue storage chamber 111 Glue; the driving mechanism 4 is movably...

Embodiment 2

[0067] On the basis of Embodiment 1, this embodiment provides a production process suitable for adopting the compound device provided in Embodiment 1, which includes: placing an aluminum frame on the plate placement platform 1, and placing the aluminum frame on the plate placement platform 1 Set the support part 100 and the glue dispensing part 110 on it; set up a number of glue storage chambers 111 in the glue dispensing part 110, and set the glue dispensing mechanism 2 in the corresponding glue storage chamber 111; set the glue injection mechanism 3 in the glue dispensing mechanism 2 Above, press the glue injection mechanism 3 toward the glue dispensing mechanism 2 to enter the corresponding glue storage chamber 111, and inject glue into the glue storage chamber 111; press the glue dispensing mechanism 2 through the aluminum frame to open the corresponding glue storage chamber 111 , through the driving mechanism 4 to push the glue in the glue storage chamber 111 to be extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com