Adjustable mold

An adjustable and moldable technology, applied in the field of shoemaking, can solve the problems of inability to produce customized insoles and meet the special needs of special groups of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

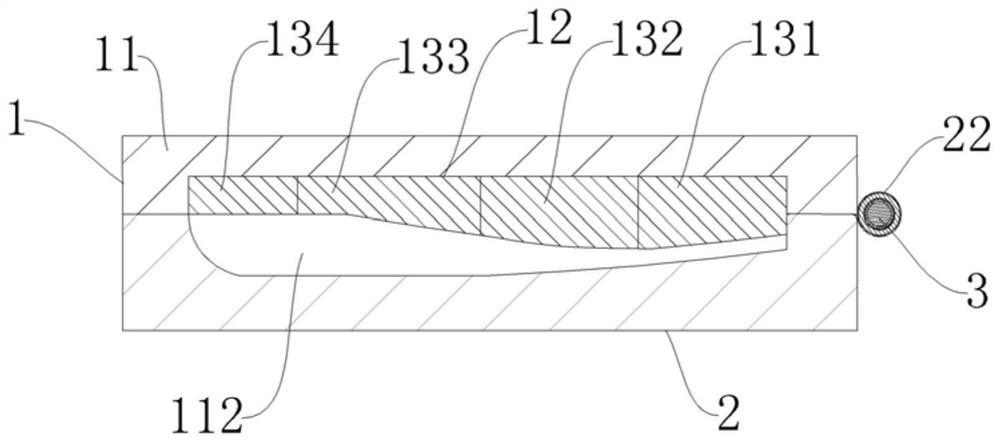

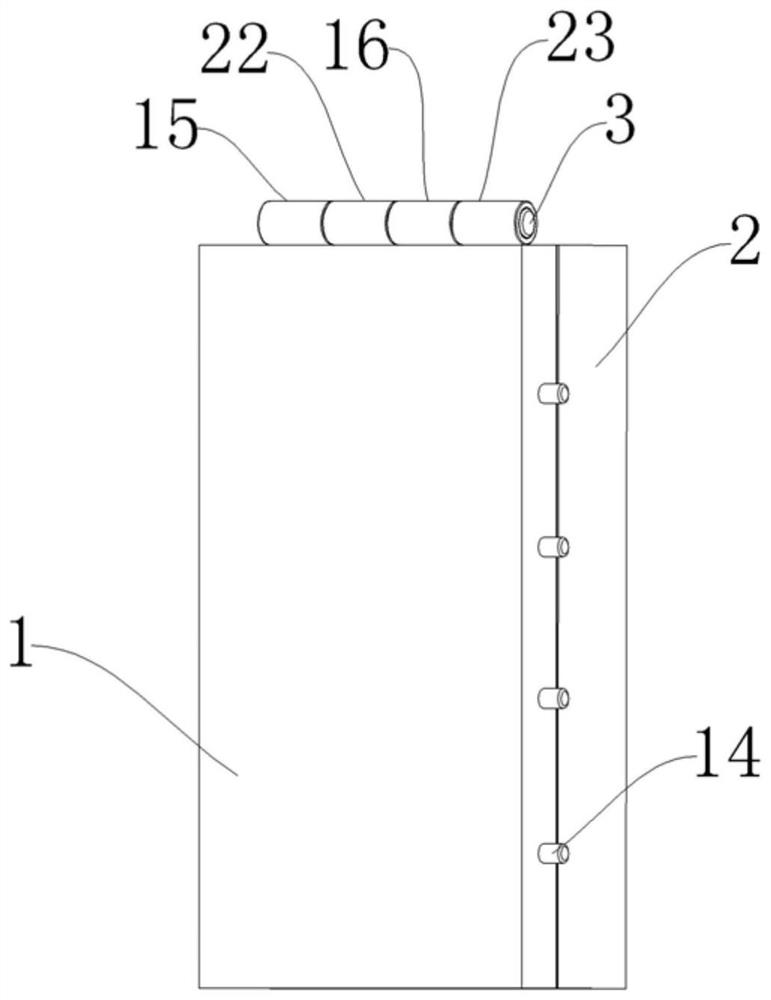

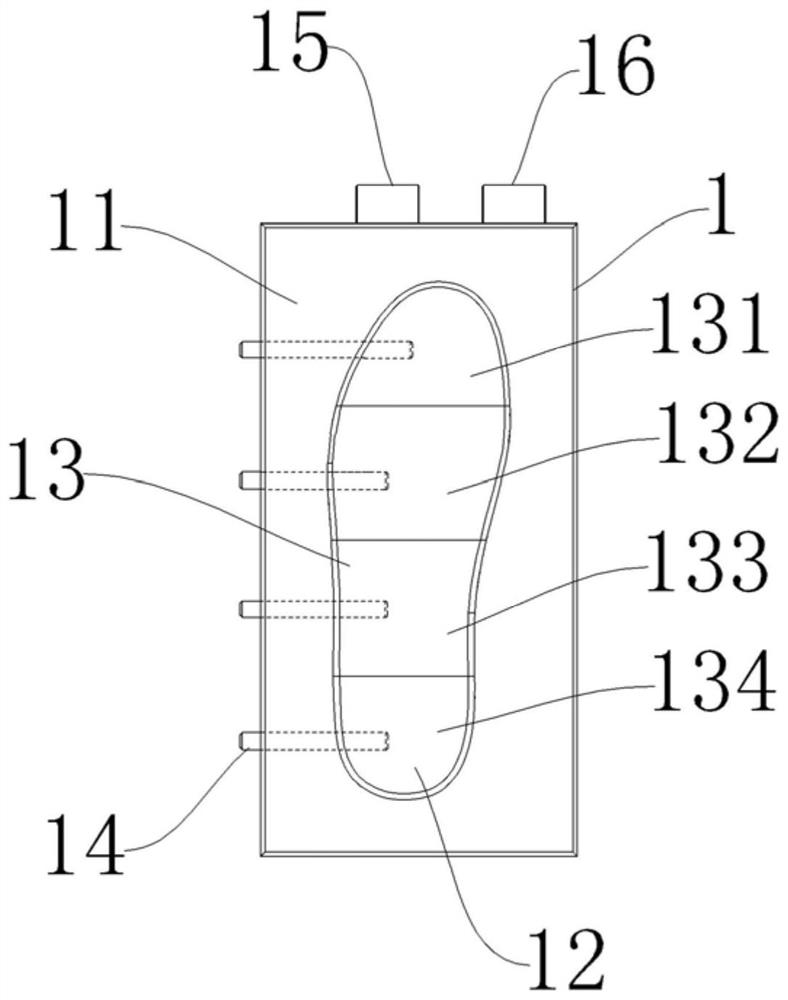

[0030] refer to Figure 1 to Figure 6 , the adjustable mold includes an upper mold 1, a lower mold 2 and a connecting shaft 3, the upper mold 1 includes an upper mold base 11, an upper template 12, a fixing member 14, a first sleeve 15 and a third sleeve 16, and the lower mold 2 A lower mold cavity 21 , a second sleeve 22 and a fourth sleeve 23 are provided.

[0031] Upper mold 1 is provided with positioning chamber 111, and upper mold plate 12 is made up of four modules 13, and four modules 13 are respectively toe area module 131, sole area module 132, arch area module 133 and heel area module 134, and the customizer can according to The toe area module 131 , the sole area module 132 , the arch area module 133 and the heel area module 134 are customized according to one's own foot shape and actual needs. The customized toe area module 131 , sole area module 132 , arch area module 133 and heel area module 134 are fully fitted with the shape and curvature of the corresponding ...

Embodiment 2

[0040] refer to Figure 5 , Figure 7 ~ Figure 9 , the adjustable mold includes an upper mold 1, a lower mold 2 and a connecting shaft 3, and the upper mold 1 includes an upper mold base 11, an upper template 12, a magnetic sheet 17, a first sleeve 15 and a third sleeve 16, and the lower mold 2. A lower mold cavity 21, a second sleeve 22 and a fourth sleeve 23 are provided.

[0041] Upper mold 1 is provided with positioning chamber 111, and upper mold plate 12 is made up of four modules 13, and four modules 13 are respectively toe area module 131, sole area module 132, arch area module 133 and heel area module 134, and the customizer can according to One or more of the toe area module 131, the sole area module 132, the arch area module 133 and the heel area module 134 are selected for personalization according to one's own foot shape and actual needs. The customized toe area module 131 , sole area module 132 , arch area module 133 and heel area module 134 are fully fitted wi...

Embodiment 3

[0050] refer to figure 2 , Figure 5 , Figure 10 ~ Figure 11 , the adjustable mold includes an upper mold 1, a lower mold 2 and a connecting shaft 3, the upper mold 1 includes an upper mold base 11, an upper template 12, a fixing member 14, a first sleeve 15 and a third sleeve 16, and the lower mold 2 A lower mold cavity 21 , a second sleeve 22 and a fourth sleeve 23 are provided.

[0051] The upper template 12 is made up of a module, which is one-piece personalized customization, and the shape and radian of the upper template 12 are fully fitted with the shape and radian of the sole of the customizer. The fixing part 14 is a bolt, and one end of the bolt passes through the side of the upper mold base 11 and is connected with the upper template 12 by threads. The upper template 12 is placed in the positioning cavity 111, and the upper template 12 is fixed in the positioning cavity 111 of the upper mold base 11 by four bolts.

[0052] The upper template 12 and the lower m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com