Water plant filter tank control system

A control system and filter technology, applied in the general control system, control/regulation system, water treatment parameter control, etc., can solve the problem of water quality and water supply decline, failure to obtain filtering effect, and timely response to failure processing And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

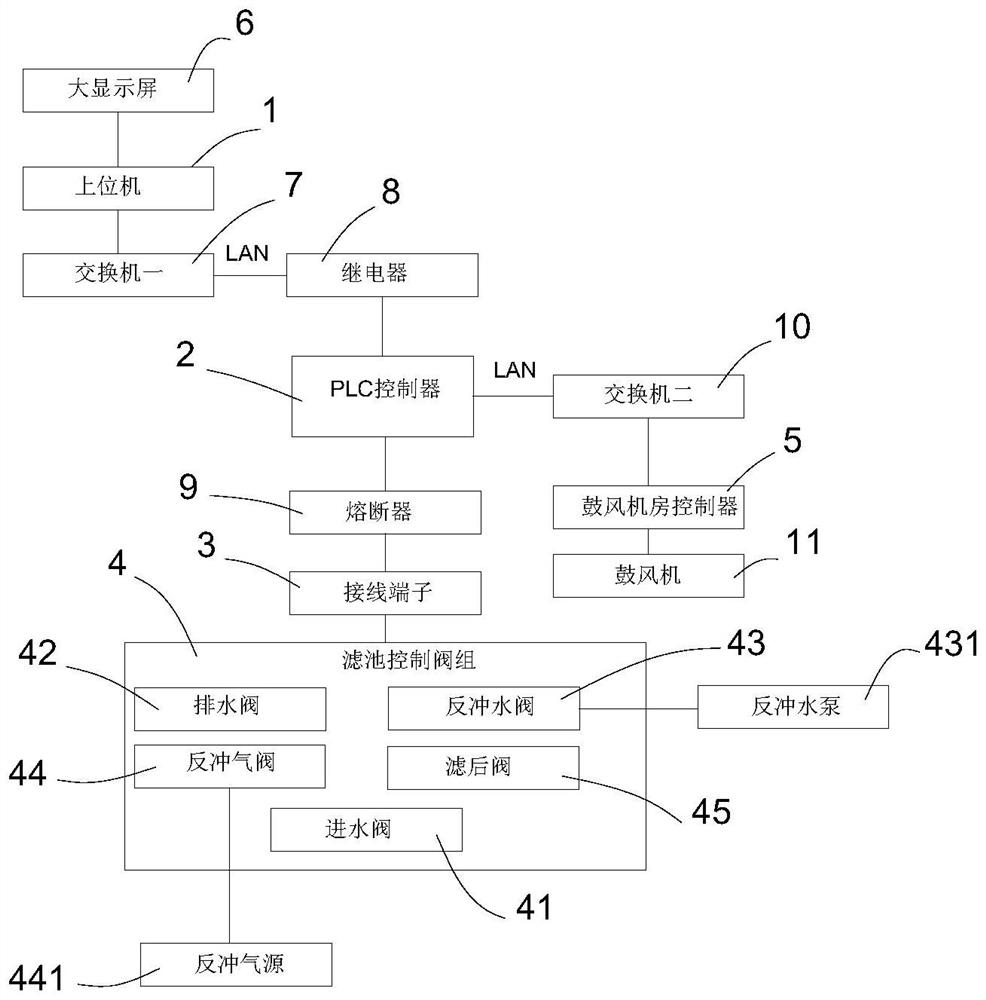

[0022] refer to figure 1 , a water plant filter control system of the present invention, comprising a host computer 1, the host computer 1 is connected to a PLC controller 2 through a LAN, and realizes data interaction, and the PLC controller 2 communicates with the filter tank through a connection terminal 3 The control valve group 4 is connected, and the PLC controller 2 is connected with the blower room controller 5 through LAN to realize data interaction. The PLC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com