A kind of milky ice-making solution and its preparation method and application

An emulsion and solution technology, applied in emulsion ice-making solution and its preparation, based on the field of static magnetic field to prepare microcrystalline fluid ice, can solve the problem of lowering the freezing point of ice-making solution, aging or agglomeration of fluid ice crystals, and reducing the supercooling of ice-making solution To achieve the effect of promoting the growth of ice nuclei, good flow performance and improving ice making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

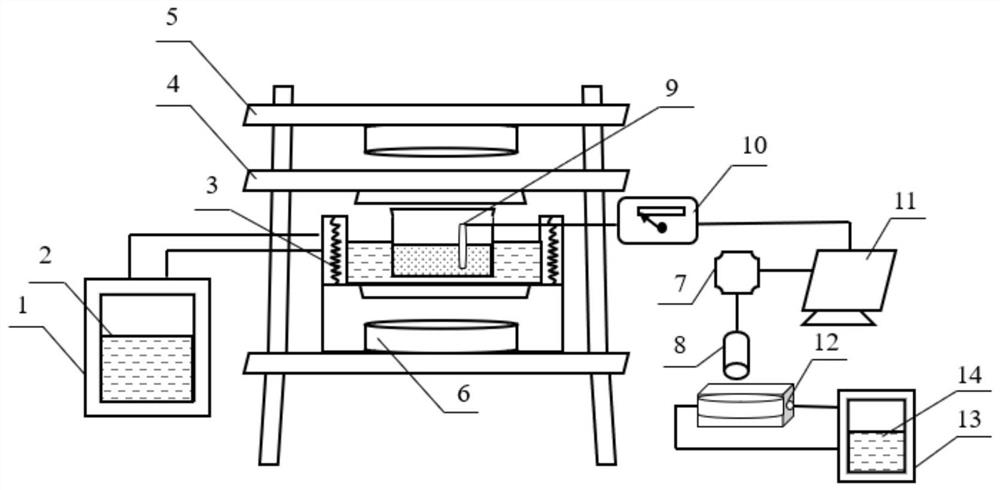

Method used

Image

Examples

Embodiment 1

[0044] Based on the volume ratio of raw materials, the milky ice-making solution is configured as:

[0045] Composition of oil phase: 60% rapeseed oil, 40% MCT; water phase: deionized water;

[0046] Based on the total volume of the oil phase and the water phase, the oil phase is 10% and the water phase is 90%;

[0047] PGPR is 3% of the total volume of oil phase and water phase;

[0048] The solution volume is 1L.

[0049] The preparation method of the milky ice-making solution is as follows: according to the formula, add PGPR to the oil phase, use a magnetic stirrer to stir at 500 rpm for 5 minutes, then add the water phase, and use a high-speed homogenizer to mix at 900 rpm for 15 minutes to obtain a coarse emulsion; The obtained crude emulsion was placed in an ultrasonic processor, and the temperature was controlled at 25° C. After 4min of ultrasonic treatment with a frequency and power of 20KHz and 100W respectively (the ultrasonic wave was dissipated in a pulsed mode, ...

Embodiment 2

[0055] Based on the volume ratio of raw materials, the milky ice-making solution is configured as:

[0056] Composition of oil phase: 60% rapeseed oil, 40% MCT; water phase: deionized water;

[0057] Based on the total volume of the oil phase and the water phase, the oil phase is 20% and the water phase is 80%;

[0058] PGPR is 5% of the total volume of oil phase and water phase;

[0059] The solution volume is 1L.

[0060] The preparation method of the milky ice-making solution is the same as that in Example 1.

[0061] The process of preparing fluid ice is as follows: control the frequency of the static magnetic field to 50 Hz, adjust the magnetic distance in the magnetic field system to 10 cm, and obtain a repulsive mode with a magnetic flux density of 0.4 T; place the milky ice-making solution in a cold bath environment at -20 °C, Put the glass ice maker containing the milky ice-making solution in the loading container of the cold bath, and apply a vertical and uniform ...

Embodiment 3

[0066] Based on the volume ratio of raw materials, the milky ice-making solution is configured as:

[0067] Composition of oil phase: 50% rapeseed oil, 50% MCT; water phase: deionized water;

[0068] Based on the total volume of the oil phase and the water phase, the oil phase is 20% and the water phase is 80%;

[0069] PGPR is 5% of the total volume of oil phase and water phase;

[0070] The solution volume is 1L.

[0071] The preparation method of the milky ice-making solution is the same as that in Example 1.

[0072] The process of preparing fluid ice is as follows: control the frequency of the static magnetic field to 50 Hz, adjust the magnetic distance in the magnetic field system to 10 cm, and obtain a repulsive mode with a magnetic flux density of 0.4 T; place the milky ice-making solution in a cold bath environment at -20 °C, Put the glass ice maker containing the milky ice-making solution in the loading container of the cold bath, and apply a vertical and uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com