Heat exchange core with flow guide switching section, heat exchanger and machining method

A technology of heat exchange core and transition section, which is applied in the field of heat exchange, can solve the problems of high cost and many processes, and achieve the effects of improving compressive strength, reducing welding processes, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

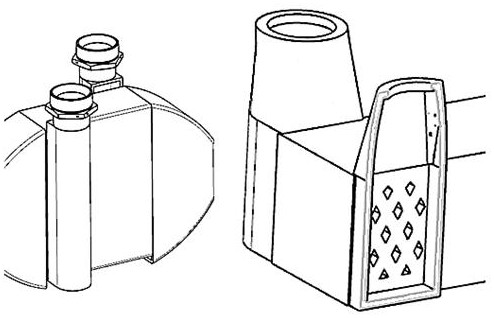

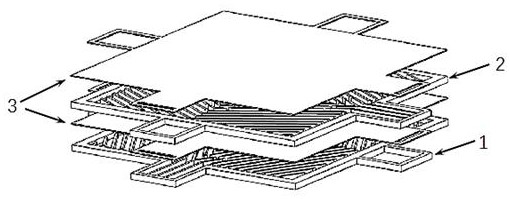

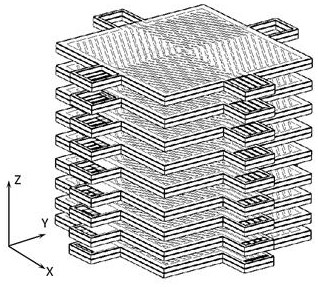

[0060] A heat exchange core with a diversion transfer section, such as Figure 2a-2b , including a plurality of stacked heat exchange units, each heat exchange unit includes a first heat exchange plate 1, a second heat exchange plate 2 and a separator 3;

[0061] The first heat exchange plate 1 is provided with an edge seal 12, and the fins 8 are arranged inside the edge seal 12; the first heat exchange plate 1 is provided with a first liquid collecting pipe 9 opposite to it and a second liquid collector 9 opposite to it. Liquid collecting pipe 10, the contour of the first liquid collecting pipe 9 and the second liquid collecting pipe 10 is the same;

[0062] Wherein, the fins 8 extend into the first liquid collection pipe 9, and each flow channel formed by the fins 8 on the first heat exchange plate 1 can communicate with the first liquid collection pipe 9, and the first liquid collection pipe The fins 8 in the tube 9 are in a through structure, and the second liquid collect...

Embodiment 2

[0068] Such as Figure 3a-3b As shown, the fins 8 are herringbone, and the fins 8 are arranged on one side of the first heat exchange plate 1 and the second heat exchange plate 2, and the fins 8 are all arranged on the first heat exchange plate 1 and the second heat exchange plate. The upper surface or the lower surface of the heat exchange plate 2; in some embodiments, the fins 8 are all arranged on the upper surfaces of the first heat exchange plate 1 and the second heat exchange plate 2, and the upper surface of the fin 8 and the edge sealing The upper surface of 12 is flush.

[0069] The fins 8 in the first liquid collection pipe 9 extending to the fluid inlet extend to connect with the edge sealing 12, cutting and guiding the fluid in the first liquid collection pipe 9 to the flow channel inside the heat exchange plate to realize liquid collection Flow distribution in the tube; the fins 8 inside the heat exchange plate are interrupted to ensure that each flow channel for...

Embodiment 3

[0086] Such as Figures 9a-9g As shown, the inlet and outlet are arranged in a diagonal line, and the fins 8 are parallel straight or zigzag rib columns; sawtooth fins, corrugated fins, and rib columns can also be used; extend to the first episode The fins 8 in the liquid pipe 9 are closed and connected, and the fluid in the first liquid collection pipe 9 is cut and guided to the flow channel inside the heat exchange plate through the fins 8 with an inclination angle β; the fins 8 with an inclination angle β are connected with The position where the straight fins 8 meet is provided with rib columns; the inclination angle β is adjusted according to the structure of the heat exchange plate and the position of the inlet and outlet, but it is not more than 90° from the mainstream direction of the fluid, and the array spacing of the rib columns is 1 to 1.5 times the pitch of the fins 8, and the fins 8 are staggered in the middle of the heat exchange plates.

[0087] The number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com