Rock mass blasting method

A technology of rock mass and pre-splitting blasting, which is applied in the field of blasting technology in open-pit mines or geotechnical engineering, can solve problems such as low half-wall porosity and poor excavation surface, and achieve the goals of reducing blasting costs, ensuring blasting safety, and maintaining stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] As an implementation manner of an embodiment of the present invention, the depth of the pre-explosion hole is (H / sinα)+k2, wherein the value of k2 is 0-1m.

[0038] As an implementation manner of an embodiment of the present invention, the diameter of the pre-explosion hole is 30-300mm.

[0039] S2, filling explosives and fillers into the pre-blasting holes at the junction, and performing pre-split blasting;

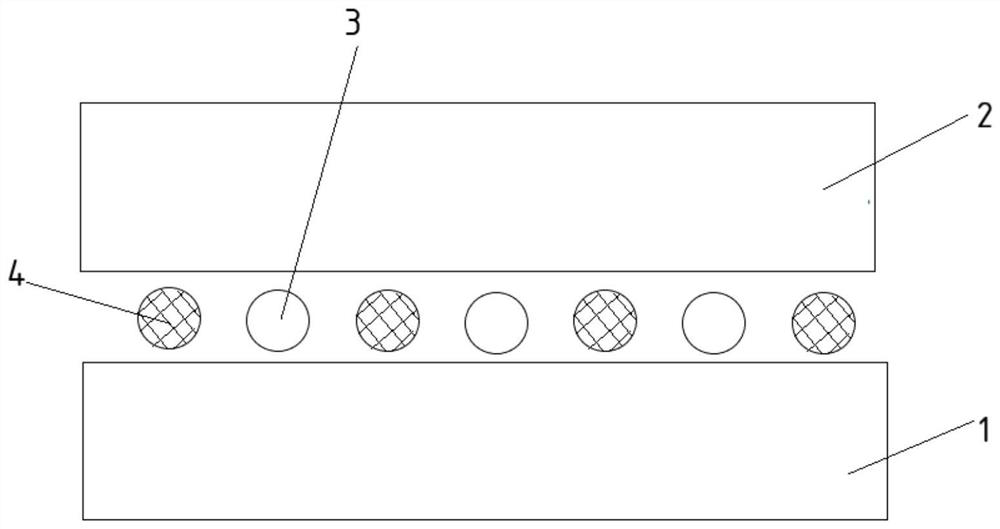

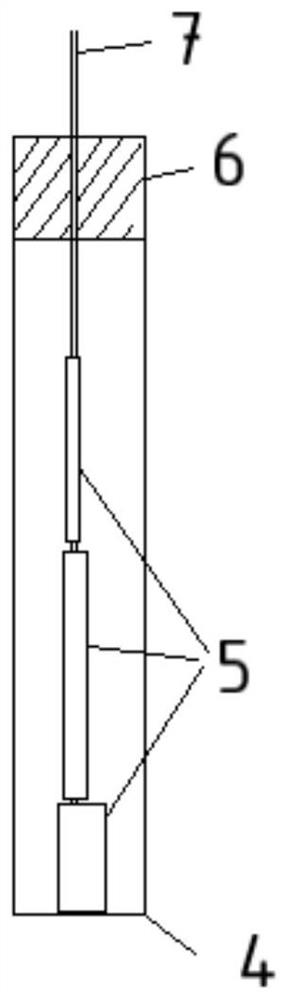

[0040] image 3 Schematic diagram of the structure for charging and packing the pre-blast hole, combined with image 3 The lower part of the pre-explosion hole 4 is equipped with an explosive 5, the upper part of the pre-explosion hole 4 is equipped with a stuffing 6, and the stuffing 6 and the explosive 5 run through a detonating cord 7.

[0041] As an implementation manner of an embodiment of the present invention, the charge uncoupling coefficient of the pre-detonation hole is 2-5.

[0042] The charge uncoupling coefficient refers to the ratio of the blast h...

Embodiment 1

[0056] 1. Investigation of blasting environment and defects

[0057] The Shuichang Iron Mine of the Mining Company of Shougang Group Co., Ltd. is a deep concave open-pit iron mine. It is in the final stage of open-pit mining. The stope space is narrow and the terrain and geological conditions are complex. More than 90% of the surrounding areas need to implement controlled blasting to control blasting vibration and blasting backlash. , the adjacent side walls need to be pre-splitting blasting, the hardness coefficient of the rock mass is f=8-12, the lithology is mixed granite, gneiss and magnetite quartzite, and more than 50% of the rock mass joints and fissures are relatively developed or the hydrogeological conditions are complex.

[0058] 2. Determination of pre-explosion holes and empty holes

[0059] (1) Determine the distance (a) between adjacent pre-blasting holes. Based on the physical and mechanical properties of the rock and soil to be blasted and the geological and t...

Embodiment 2

[0072] 1. Investigation of blasting environment and defects

[0073] The Shuichang Iron Mine of the Mining Company of Shougang Group Co., Ltd. is a deep concave open-pit iron mine. It is in the final stage of open-pit mining. The stope space is narrow and the terrain and geological conditions are complex. More than 90% of the surrounding areas need to implement controlled blasting to control blasting vibration and blasting backlash. , the adjacent side walls need to be pre-splitting blasting, the hardness coefficient of the rock mass is f=8-12, the lithology is mixed granite, gneiss and magnetite quartzite, and more than 50% of the rock mass joints and fissures are relatively developed or the hydrogeological conditions are complex.

[0074] 2. Determination of pre-explosion holes and empty holes

[0075] (1) Determine the distance (a) between adjacent pre-blasting holes. Based on the physical and mechanical properties of the rock and soil to be blasted and the geological and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com