Tire label and preparation method thereof

A label and tire technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of tire label structure deviation, affecting the performance consistency of tire labels, etc., to prevent falling off, excellent registration, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

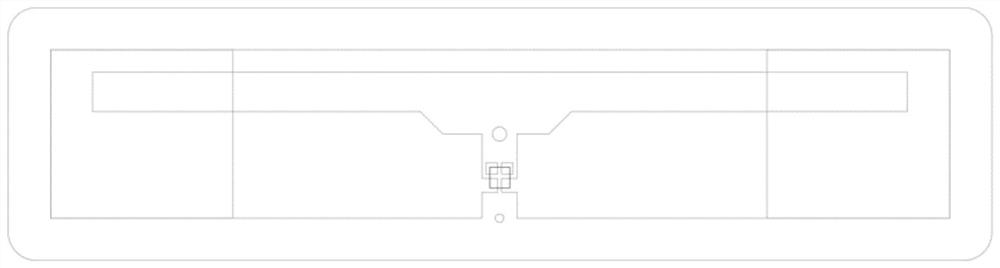

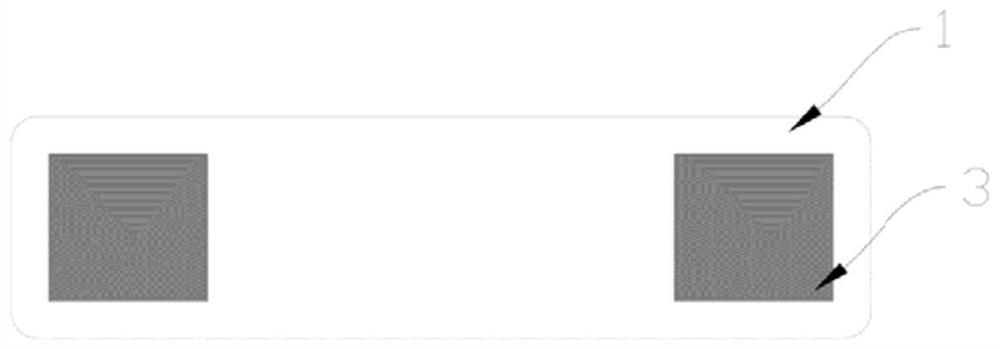

Image

Examples

Embodiment 2

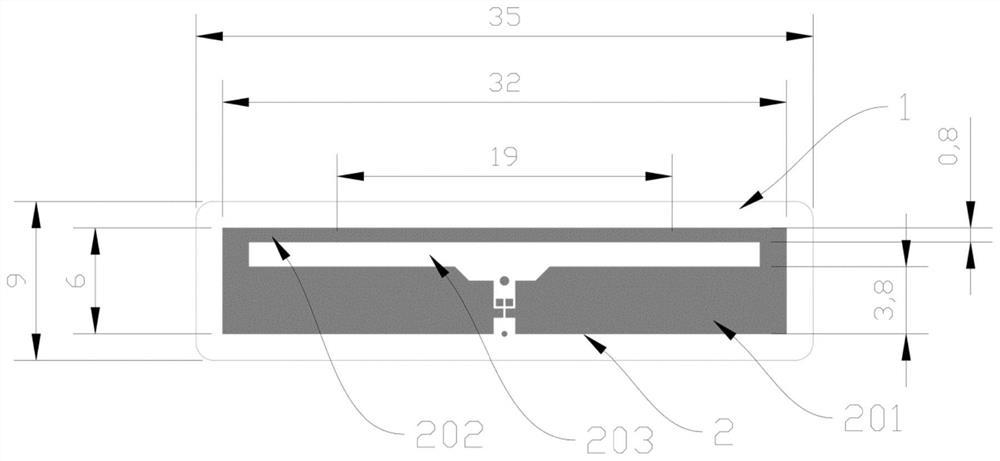

[0058] This embodiment is substantially the same as the embodiment, and the difference is:

[0059] The thickness of the substrate 1 is 95 μm;

[0060] The height of the antenna pattern is 5.5 mm, and the width of the antenna pattern is 31 mm, wherein the height of the arm is 0.7 mm, and the height of the large arm is 3.7 mm;

[0061] The main antenna 2 and the antenna 3 are made of aluminum, the main antenna 2 and the attachment antenna 3 having a thickness of 13 μm.

Embodiment 3

[0063] This embodiment is substantially the same as the embodiment, and the difference is:

[0064] The thickness of the substrate 1 is 105 μm;

[0065] The height of the antenna pattern is 6.5 mm, and the width of the antenna pattern is 33 mm, wherein the height of the arm is 0.9 mm, and the height of the large arm is 3.9 mm;

[0066] The main antenna 2 and the antenna 3 are made of aluminum, the main antenna 2 and the attachment antenna 3 having a thickness of 17 μm.

Embodiment 4

[0068] A method of preparing a tire label is further provided for preparing a tire label as described in an embodiment from one to three, comprising the steps of:

[0069] S1, the aluminum foil is compounded and solidified on both sides of the substrate; the material used in the aluminum foil used in this example is a prior art, which is not particularly introduced to how the aluminum foil is composite.

[0070] S2, using the APS 20000 flexible circuit printing equipment, with a printing speed of 4 m / min, a cure condition is printed by a process parameter of 280V / 180 μs using a 280V / 180 μs of the process parameters of 280V / 180 μs, and is printed on the substrate. The pattern of the main antenna, the other side of the substrate, positioned and closing the primary antenna, and printed the pattern of the accessory antenna; The roller is positioned and the primary antenna, which does not provide a pattern of one-sided attached antenna of the primary antenna, thereby obtaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com