Transfer device with raw material screening structure for beverage production

A technology for transfer devices and appliances, which is applied in application, filtration, solid separation, etc., and can solve the problems of inconvenient automatic screening of fruits and vegetables and residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

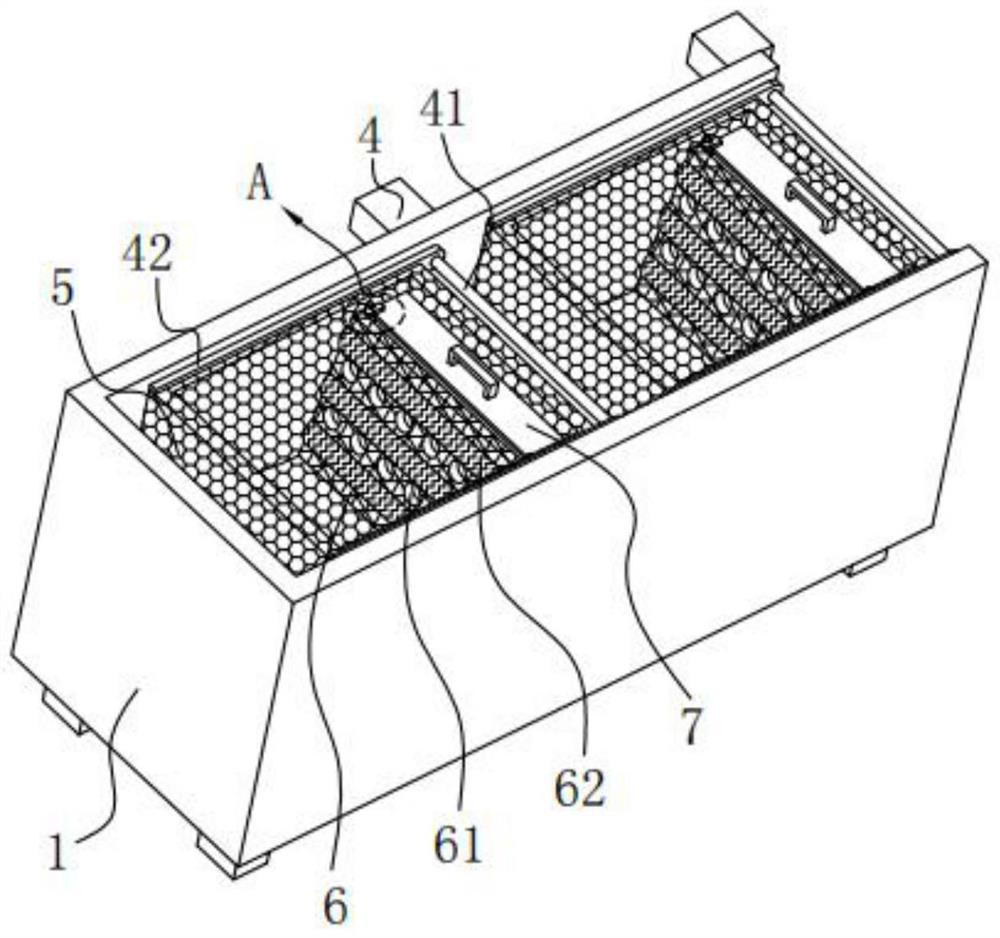

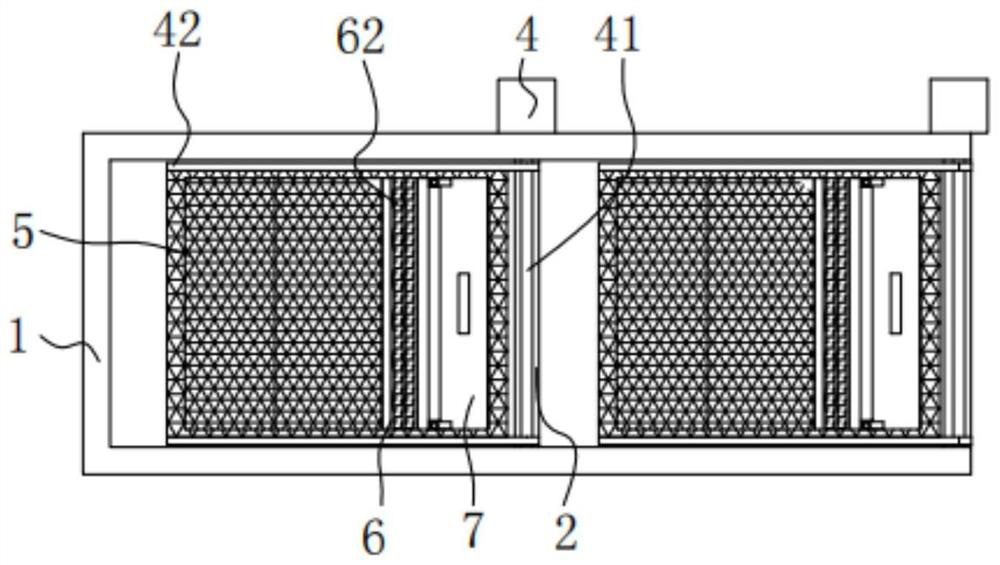

[0038] A transshipment device with raw material screening structure based on beverage production includes: a cleaning tank 1; There is an isolation filter screen 21; an aeration mechanism 3, the aeration mechanism 3 is installed under the cleaning tank 1; a turning motor 4, the turning motor 4 is installed on the surface of the cleaning tank 1, and the turning motor 4 The output end of the output end is fixedly installed with a turning shaft 41, and the surface of the turning shaft 41 is fixedly equipped with a turning frame 42; the transfer frame 5, the surface of the transfer frame 5 is fixedly installed on the surface of the turning frame 42; , the surface of the drainage inclined plate 6 is fixedly installed on the inside of the transfer frame 5, the drainage inclined plate 6 is provided with a screening hole 61, and the surface of the drainage inclined plate 6 is fixedly equipped with a speed reducer 62; 7. The surface of the collection frame 7 is installed on one side of...

Embodiment 2

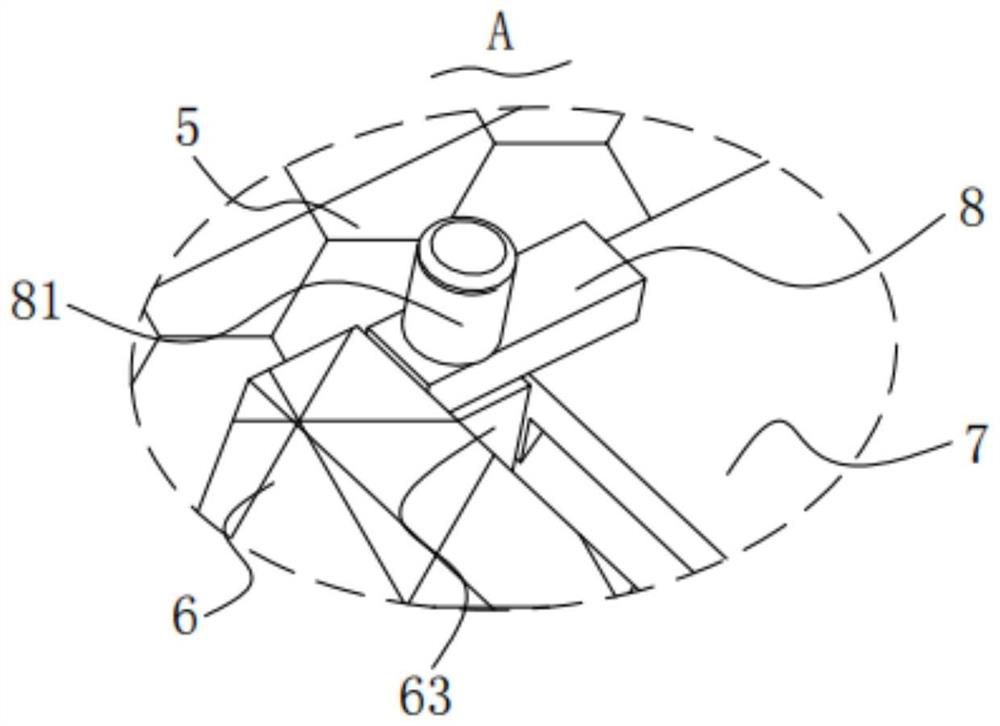

[0062] A limit slide plate 63 is fixedly installed on one side of the drainage ramp 6, a drainage plate 71 and a blocking plate 72 are installed on the inside of the collection frame 7, and a connection plate 8 is installed on the outer surface of the collection frame 7, and the connection plate 8 is equipped with locking screw shaft 81.

[0063] The limit slide plate 63 provides a limit for the installation of the collection frame 7, so as to facilitate the movable installation of the collection frame 7. After the collection frame 7 is installed, it is convenient to tighten and fix it through the locking screw shaft 81, so as to facilitate the installation and disassembly of the collection frame 7. This facilitates the automatic screening and selection of raw material residues and unqualified fruits and vegetables collected inside the collection frame 7. The collection frame 7 is equipped with a drainage plate 71 and a baffle plate 72, which can maintain the stability of mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com