Electronic cigarette tar injection structure

An oil filling structure and e-cigarette technology, applied in the field of e-cigarettes, can solve problems such as e-liquid leakage, affect user experience, and lack of automatic sealing function, so as to avoid odor, improve use convenience, and avoid e-liquid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

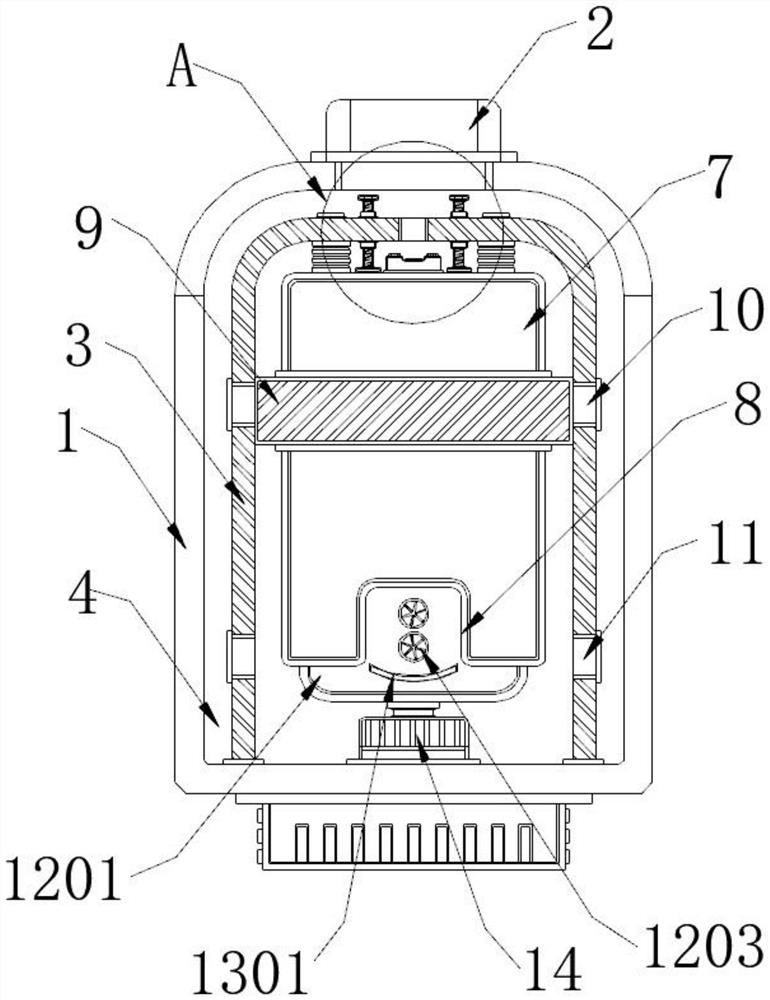

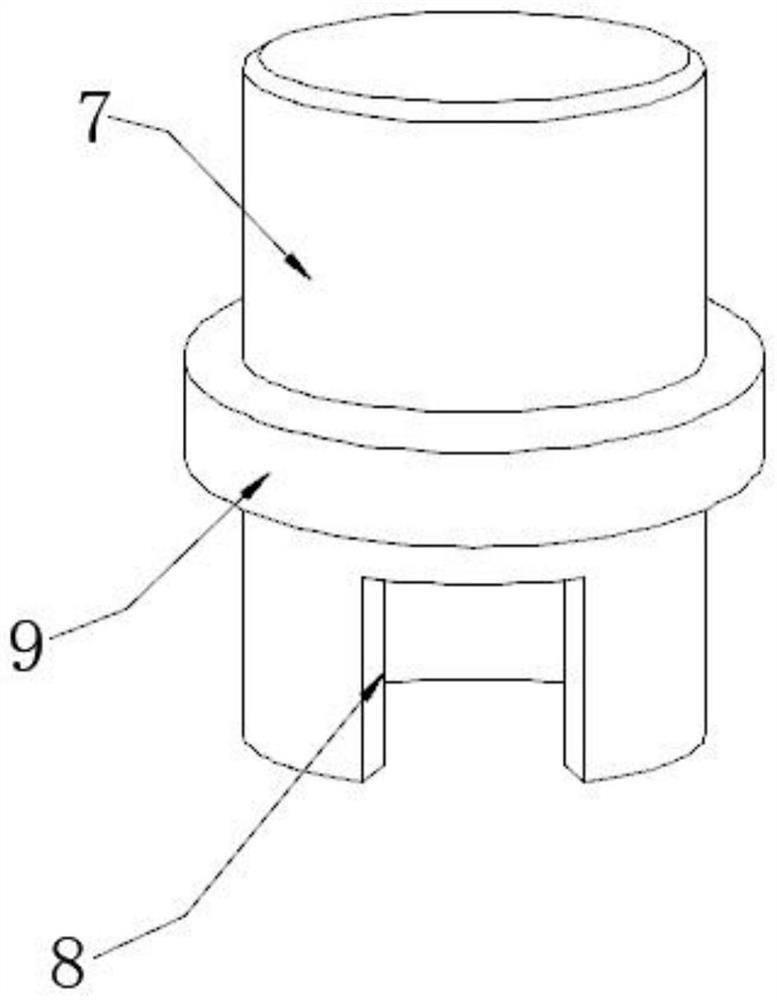

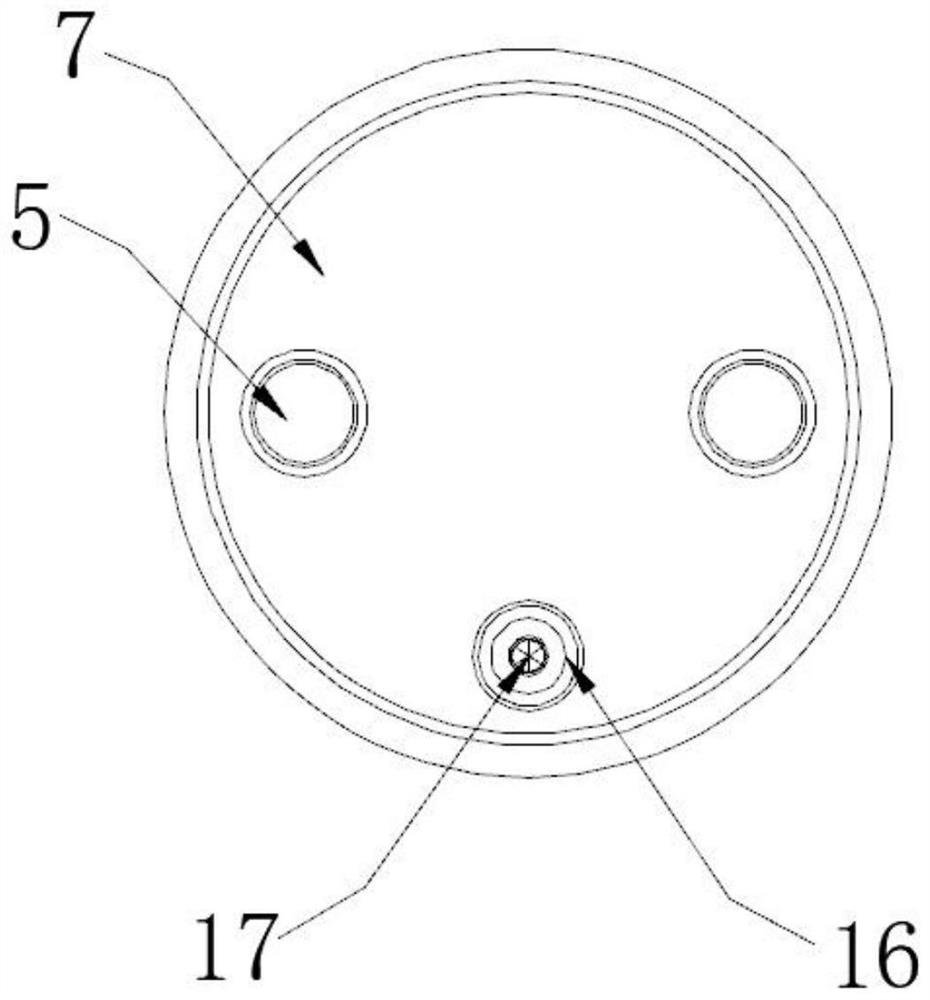

[0030] see Figure 1-8 , the present invention provides a technical solution: an electronic cigarette oil filling structure, including a microphone shell 1, a baffle 7 and an oil storage assembly 12, a suction port 2 is provided on the top outside of the microphone shell 1, and the microphone shell 1 A partition board 3 is arranged on the inner side of the partition board 3, and a flue gas channel 4 is opened between the partition board 3 and the microphone shell 1, and a telescopic air bag 5 is arranged on both sides of the interior of the partition board 3, and the top two sides of the telescopic air bag 5 are opened There is an air extraction groove 6, and the baffle plate 7 is arranged on both sides of the bottom of the telescopic air bag 5, and the front outer side of the baffle plate 7 is provided with a liquid outlet groove 8, and the oil storage assembly 12 is arranged on the inner side of the baffle plate 7, and the oil storage assembly 12 It includes an oil storage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com