Accurate dust removal method and system

A technology of dust removal, which is applied in the field of precise dust removal system, precise dust removal, and dust removal, can solve the problems of inability to remove dust, increase the dust content of the outlet, and increase operating costs, so as to meet the needs of fast screening, The effect of improving accuracy and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

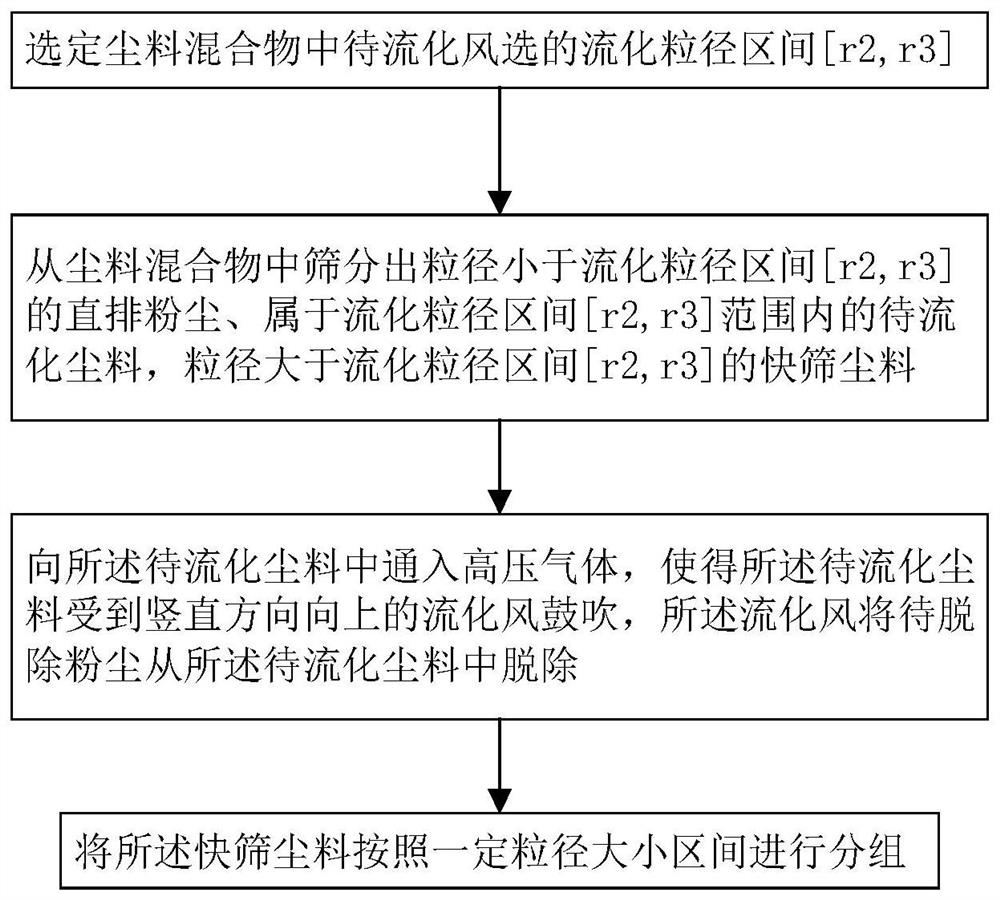

[0075] According to a first embodiment of the present invention, a method for accurately removing dust is provided:

[0076] A method for accurately removing dust, the method comprising the following steps:

[0077] 1) Select the fluidized particle size interval [r 2 ,r 3 ];

[0078] 2) Sieve out the particle size smaller than the fluidized particle size range [r 2 ,r 3 ]’s direct discharge dust, which belongs to the range of fluidized particle size [r 2 ,r 3 ] range of dust to be fluidized, the particle size is greater than the fluidized particle size interval [r 2 ,r 3 ]’s quick-screen dust material;

[0079] 3) Pass high-pressure gas into the dust material to be fluidized, so that the dust material to be fluidized is blown by the vertical upward fluidization wind, and the fluidization wind blows the dust to be removed from the fluidized dust material to be fluidized Removed from the dust material.

[0080] Preferably, the method also includes the following steps: ...

Embodiment 1

[0107] A method for accurately removing dust, the method comprising the following steps:

[0108] 1) Select the fluidized particle size interval [r 2 ,r 3 ];

[0109] 2) Sieve out the particle size smaller than the fluidized particle size range [r 2 ,r 3 ]’s direct discharge dust, which belongs to the range of fluidized particle size [r 2 ,r 3 ] range of dust to be fluidized, the particle size is greater than the fluidized particle size interval [r 2 ,r 3 ]’s quick-screen dust material;

[0110] 3) Pass high-pressure gas into the dust material to be fluidized, so that the dust material to be fluidized is blown by the vertical upward fluidization wind, and the fluidization wind blows the dust to be removed from the fluidized dust material to be fluidized Removed from the dust material.

Embodiment 2

[0112] Repeat embodiment 1, only this method also comprises the following steps:

[0113] 4) Group the quick-sieving dust materials according to certain particle size intervals to obtain A3, A4, ..., An, a total of (n-2) groups of the quick-sieving dust materials, the A3, A4, ... The particle size of the dust material between the groups An and An increases gradually, and high-pressure gas is injected into the groups A3, A4, ..., and An to blow off the dust attached to the large particles, and the A3, A4, ... ... and the wind speed of the high-pressure gas in the An group are respectively marked as u 3 , u 4 ,...,u n . The wind speed of passing high-pressure gas in the described A3, A4, ..., An group satisfies the following relationship: u 3 > u 4 >... >u n .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap