Anti-folding control system for semi-trailer

A technology of folding control and semi-trailer, which is applied in the direction of braking safety system, brakes, vehicle components, etc., and can solve problems such as difficult maneuvering, lateral movement, and tractor deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

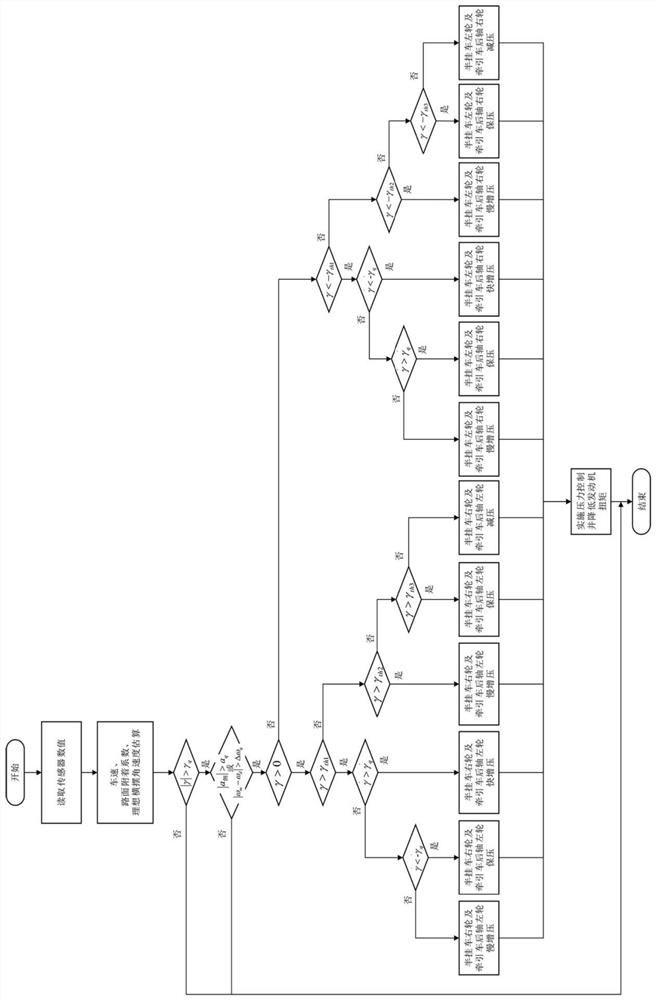

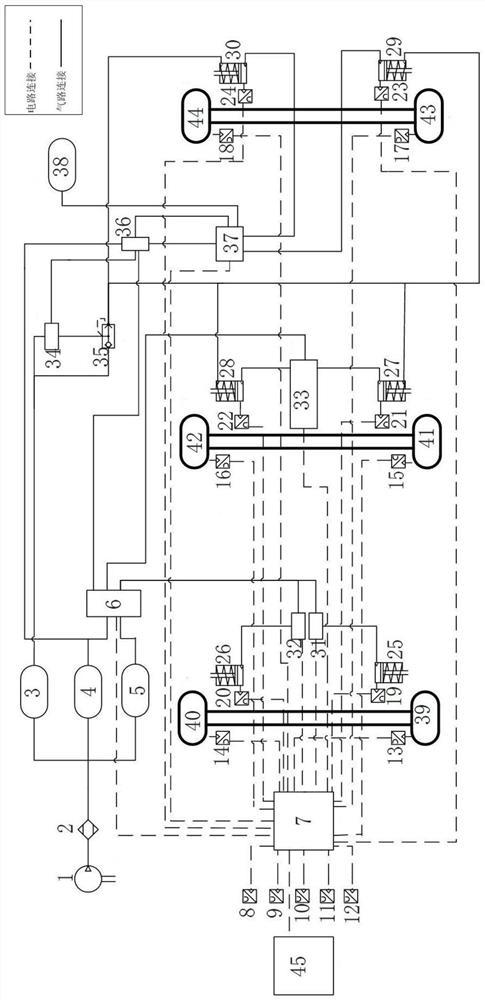

[0076] The invention provides an anti-folding control system for a semi-trailer, which includes an electronic control unit 7, a yaw rate sensor 8, a lateral acceleration sensor 9, a steering wheel angle sensor 10, a folding angle sensor 11, a folding angular rate sensor 12, and a tractor rear axle Dual-channel bridge control valve 33, semi-trailer dual-channel bridge control valve 37, brake air chamber, wheel speed sensor, brake air chamber pressure sensor, the electronic control unit 7 communicates with the yaw rate sensor 8, Lateral acceleration sensor 9, steering wheel angle sensor 10, folding angle sensor 11, folding angular velocity sensor 12, tractor rear axle dual-channel bridge control valve 33, semi-trailer dual-channel bridge control valve 37, wheel speed sensor, brake chamber Pressure sensor is connected with engine 45, can acquire data and carry out control; Control process comprises the following steps:

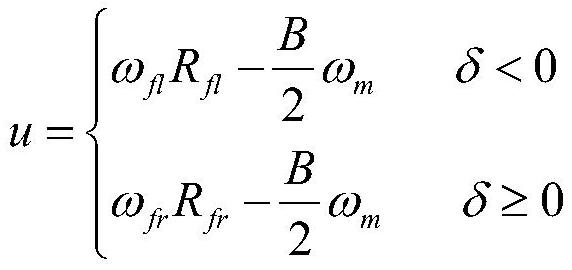

[0077] Step 1), the electronic control unit 7 is preset wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com