Grading method of ultra-high performance concrete

An ultra-high performance, concrete technology, used in the field of concrete test research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

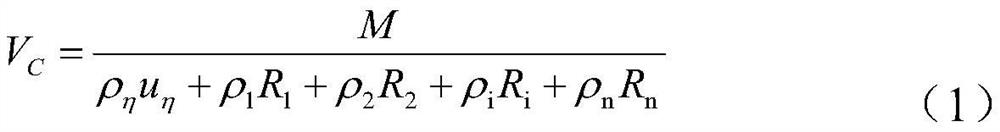

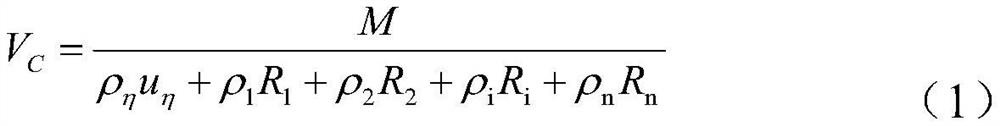

Method used

Image

Examples

Embodiment 1

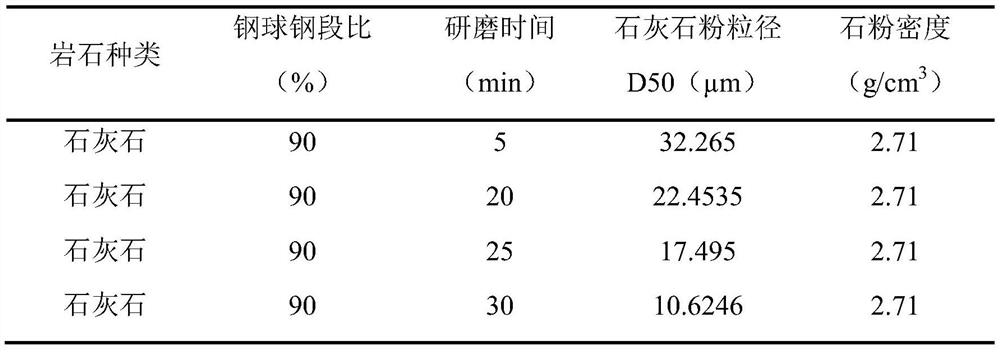

[0036] Under the same match, use different fine limestone powder for further description of the invention, the parameters of the limestone powder using limestone powder are shown in Table 1:

[0037] Table 1 Process parameters and physical performance indicators for stone powder production

[0038]

[0039] Example 1 Table 2 ratio using micro-fed:

[0040] Table 2

[0041]

[0042] Note: The above ratios are the ratio of volume.

[0043] For the first time, it is recommended to select the initial anhydrous ethanol and gelling material to be selected for the proportion of the initial anhydrous ethanol and the gelling material. Subsegrade is gradually reduced to the solid concentration, or the mixture cannot be Become a paste.

[0044] Before experimenting, the density of the gelling material was measured to determine the specific amount of the gelling material, the measurement of the density of the gelling material was detected by GB / T 208-2014 cement density assay. Table 3 i...

Embodiment 2

[0083] In order to verify the effectiveness of the method of the present invention, a three sets of micro-levels are mixed with UHPC, and the UHPc having a better UHPc is mixed with a 0.2 hydrophone ratio, Table 10 is used in the example. UHPC coordination ratio.

[0084] Table 10

[0085]

[0086]

[0087] The sand used in this example is the river sand of the fine mode 2.5, the mud is less than 0.5; the steel fiber used is a copper-plated steel fiber having a length of 12 mm, and the water reduction agent is a polycarboxylic acid having more than 30% reduction efficiency. High efficiency water reduction.

[0088] In accordance with Table 10, the quality of material required is calculated, in the laboratory, in accordance with the mass quality of the calculation material, weigh the balance accuracy of ± 1g at the time of weighing.

[0089] The mixture was stirred using a cement rubber mixer, and all gelation materials and sand were first stirred at a mixing pan, stirring the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com