Methane synthesis catalyst layered carrier and preparing method thereof

A catalyst layer, methane synthesis technology, applied in the field of catalysis, to achieve the effects of good hydrothermal stability, large specific surface area and high reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

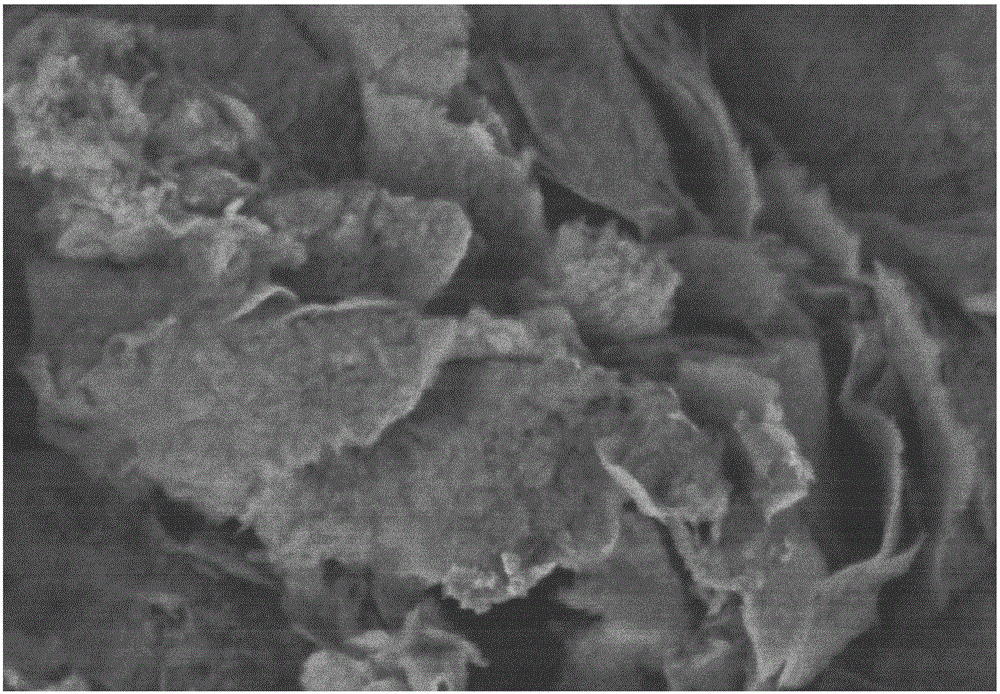

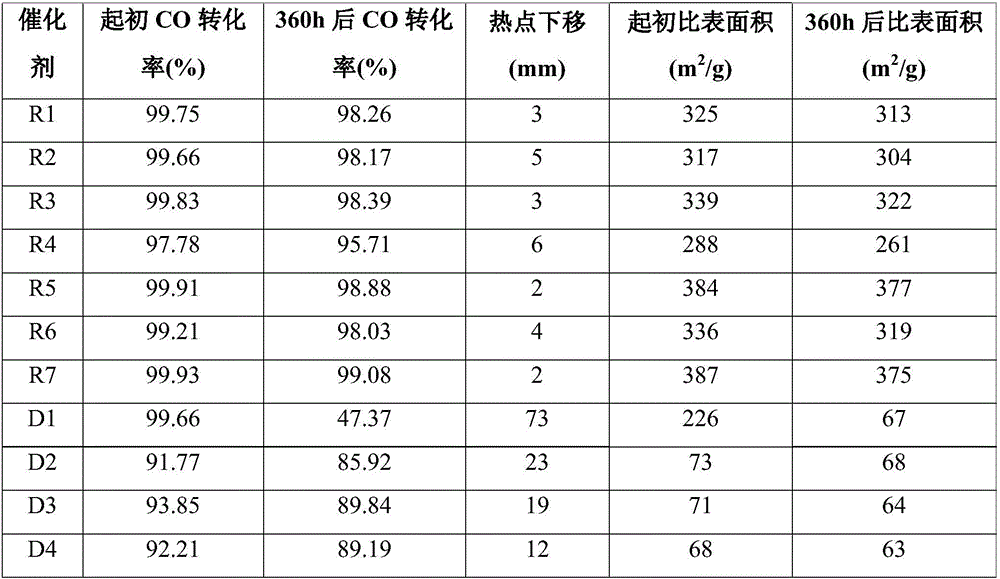

[0038] Take 200mL of deionized water, add 54.43g of aluminum acetate and 32.04g of magnesium acetate, stir until completely dissolved to make salt solution A. 151.57g sodium silicate nonahydrate was made into solution B of 20% mass concentration. Solutions A and B were mixed, and a buffer solution of sodium bicarbonate and sodium hydroxide was added with stirring until the pH value was 13.0 to obtain cloudy solution C. Finally, put the cloudy solution C into a high-pressure reactor, stir and crystallize at 300°C for 8 hours, filter and wash until the pH value of the washing liquid is less than 8.0, dry at 120°C for 2 hours, press into tablets, and bake at 450°C for 3 hours. Hours, the layered carrier of the methane synthesis catalyst was obtained, and the scanning electron microscope photos were as follows:figure 1 As shown, it appears as a layered structure. The obtained carrier was impregnated in the mixed solution of nickel nitrate and lanthanum nitrate to obtain 15% Ni co...

Embodiment 2

[0040] Take 280mL of deionized water, add 50.02g of aluminum nitrate and 66.60g of magnesium nitrate, stir until completely dissolved to make salt solution A. 189.47g sodium silicate nonahydrate was made into solution B of 20% mass concentration. Mix solutions A and B, and add a buffer solution of sodium bicarbonate and sodium hydroxide with stirring until the pH value is 11.0 to obtain cloudy solution C. Finally, put the cloudy liquid C into a high-pressure reactor, stir and crystallize at 140°C for 3 hours, filter and wash until the pH of the washing liquid is less than 8.0, dry at 120°C for 2 hours, press into tablets, and bake at 450°C for 3 hours. Hours, the layered carrier of the methane synthesis catalyst was obtained. The obtained carrier was impregnated in the mixed solution of nickel nitrate and lanthanum nitrate to obtain 15% Ni content, La 2 o 3 Layered methane synthesis catalyst R2 with a content of 5%.

Embodiment 3

[0042] Take 260mL of deionized water, add 20.41g of aluminum acetate and 85.43g of magnesium acetate, stir until completely dissolved to make salt solution A. 198.94g sodium silicate nonahydrate was made into solution B of 20% mass concentration. Mix solutions A and B, and add a buffer solution of sodium bicarbonate and sodium hydroxide with stirring until the pH value is 9.0 to obtain cloudy solution C. Finally, put the cloudy liquid C into a high-pressure reactor, stir and crystallize at 210°C for 12 hours, filter and wash until the pH value of the washing liquid is less than 8.0, dry at 120°C for 2 hours, press into tablets, and bake at 450°C for 3 hours. Hours, the layered carrier of the methane synthesis catalyst was obtained. The obtained carrier was impregnated in the mixed solution of nickel nitrate and lanthanum nitrate to obtain 15% Ni content, La 2 o 3 Layered methane synthesis catalyst R3 with a content of 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com