Repair device and repair method for concrete drilling coring

A technology for drilling and coring and concrete, which is used in building maintenance, construction, building construction, etc., can solve the problems of insufficiency, bubble generation, material waste grouting, etc., to achieve the effect of convenient operation, avoid waste, and ensure durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

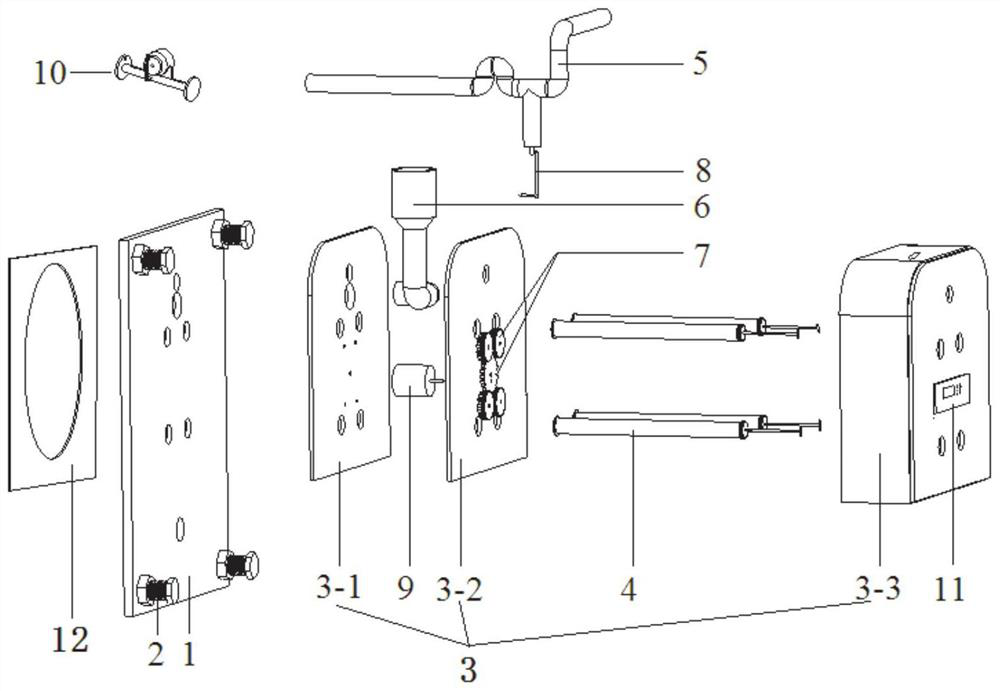

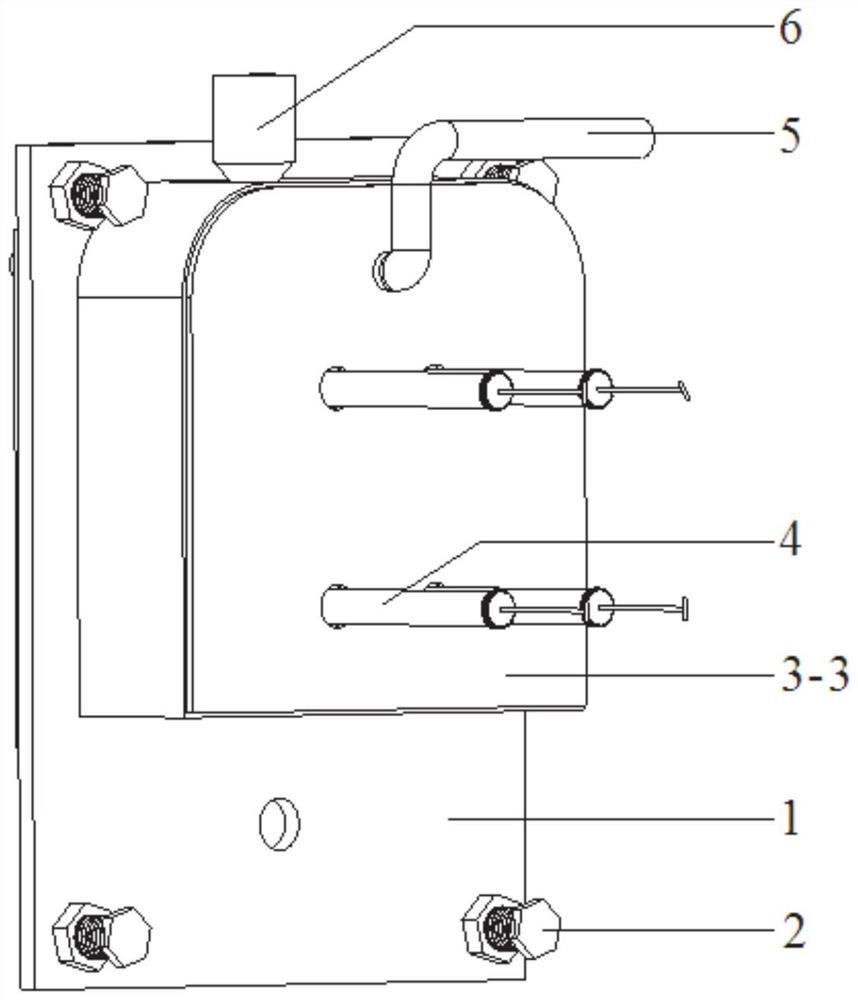

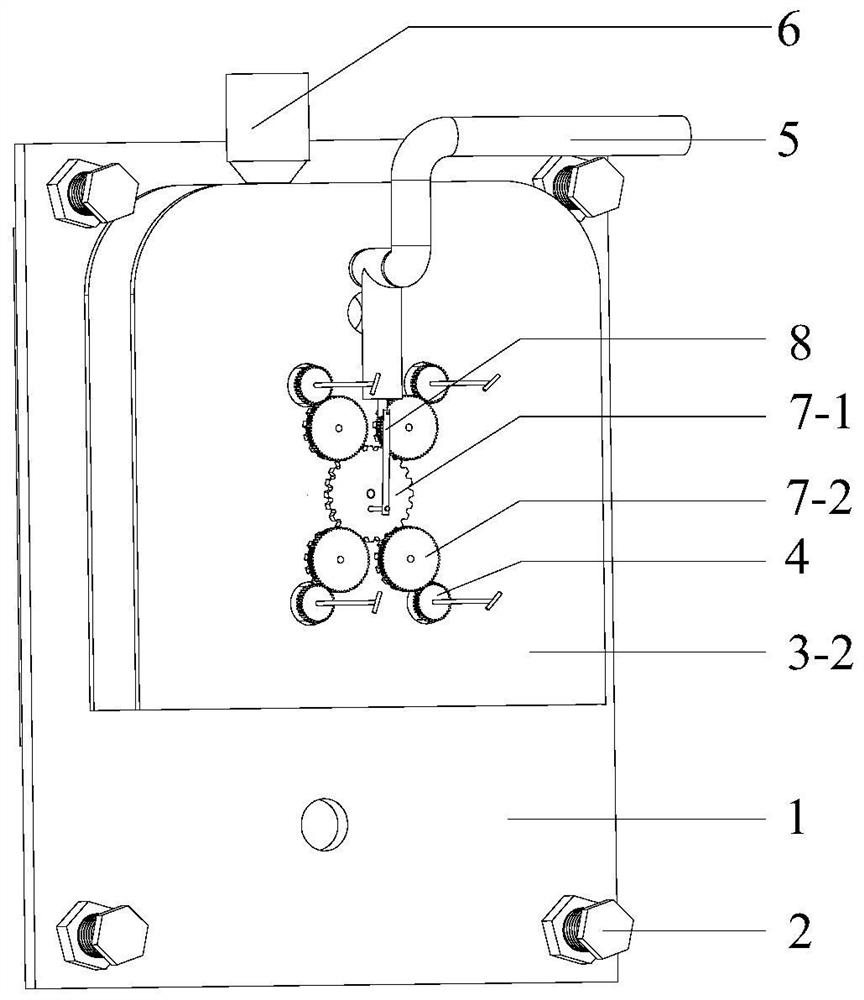

[0051] In a typical embodiment of the present invention, such as Figure 1-Figure 9 As shown, a repair device for concrete drilling and coring is proposed, including a panel 1, a fixed rod 2, a fixed plate 3, a vibrating rod 4, a discharge pipe 5, a filling pipe 6, a transmission gear set 7, and a linkage rod 8 , the first motor 9, the detector 10, the control system 11 and the rubber pad 12.

[0052] Among them, the fixing plate 3 and the rubber pad 12 are installed on both sides of the panel 1 respectively, and the rubber pad 12 is located on the side where the panel 1 is in contact with the concrete structure, which is used to reduce the damage of the panel 1 to the surface of the concrete structure, and can ensure that the panel 1 is in contact with the concrete structure. The tightness between the concrete structures, the fixed plate 3 is located on the other side of the panel 1.

[0053] The panel 1 is provided with a grouting hole 1-3, a grouting hole 1-4, a vibrating ...

Embodiment 2

[0082] In another typical embodiment of the present application, a method for repairing a repairing device for concrete drilling and coring as described in Embodiment 1 is provided. In this embodiment, the grouting material adopts epoxy mortar with certain fluidity, and the specific steps as follows:

[0083] (1) Each device is assembled and welded into shape, and the detector 10 is installed on the innermost side of the upper edge of the hole at a position away from the dumbbell-shaped rod 10-1, so as to prevent the movement of the dumbbell-shaped rod 10-1 from being restricted inside the hole and affect the detection effect;

[0084]Since the core is drilled on the side wall of the concrete structure, the direction of the hole is perpendicular to the horizontal direction of the concrete side wall, so the inner wall of the hole can be divided into the inner curved side wall of the hole and the inner vertical side wall of the hole. The innermost side of the edge refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com