Method for preventing side expansion of window frame gap filling foaming agent

A foaming agent and anti-expansion technology, applied in the fastening/covering of joints, windows/doors, building components, etc., can solve the problems of window edge leakage, foaming agent through seams, and affecting the installation quality of window frames, etc. , to achieve the effect of eliminating leakage, avoiding seams, and improving installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

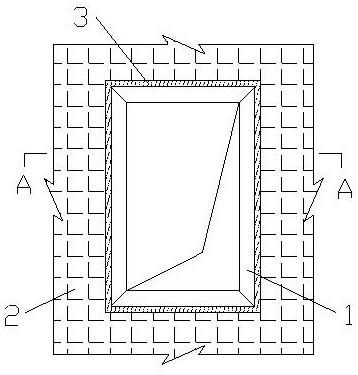

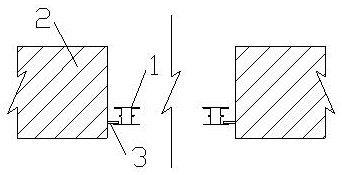

[0014] Example figure 1 with figure 2 Shown, the method that the present invention prevents the side expansion of window frame caulking foaming agent comprises the steps:

[0015] Step 1. Make the anti-expansion rubber strip 3 according to the width of the gap between the window frame 1 and the wall 2 plus the thickness required for fixing the embedded gap. The length of the anti-expansion rubber strip 3 is consistent with the width and height of the window opening;

[0016] Step 2. Install the anti-expansion rubber strip 3 in the gap between the window frame 1 and the wall 2 on the water-facing surface of the window frame 1. One side of the anti-expansion rubber strip 3 is fixed on the window wall with a nail gun or glue, and the other side is Fix it on the inner wall of the window frame 1 groove with glue;

[0017] Step 3. After the fixed glue of the anti-expansion rubber strip 3 is solidified, use a foaming agent to fill the gap on the back surface of the window frame 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com