Inner container pulling and riveting structure, manufacturing method thereof and steaming and baking machine

A manufacturing method and pull riveting technology, applied in the direction of connecting components, rivets, mechanical equipment, etc., can solve problems such as steam leakage, cracks, whitening, etc., and achieve the effect of convenient sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

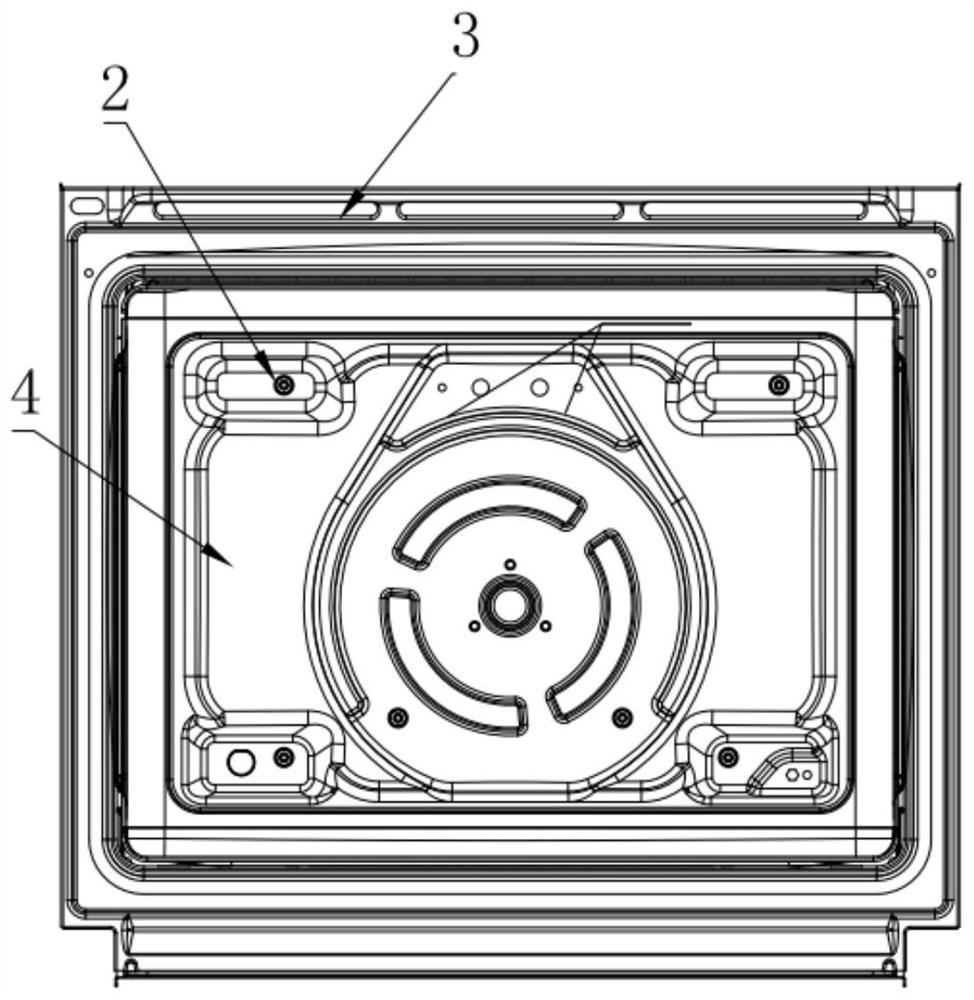

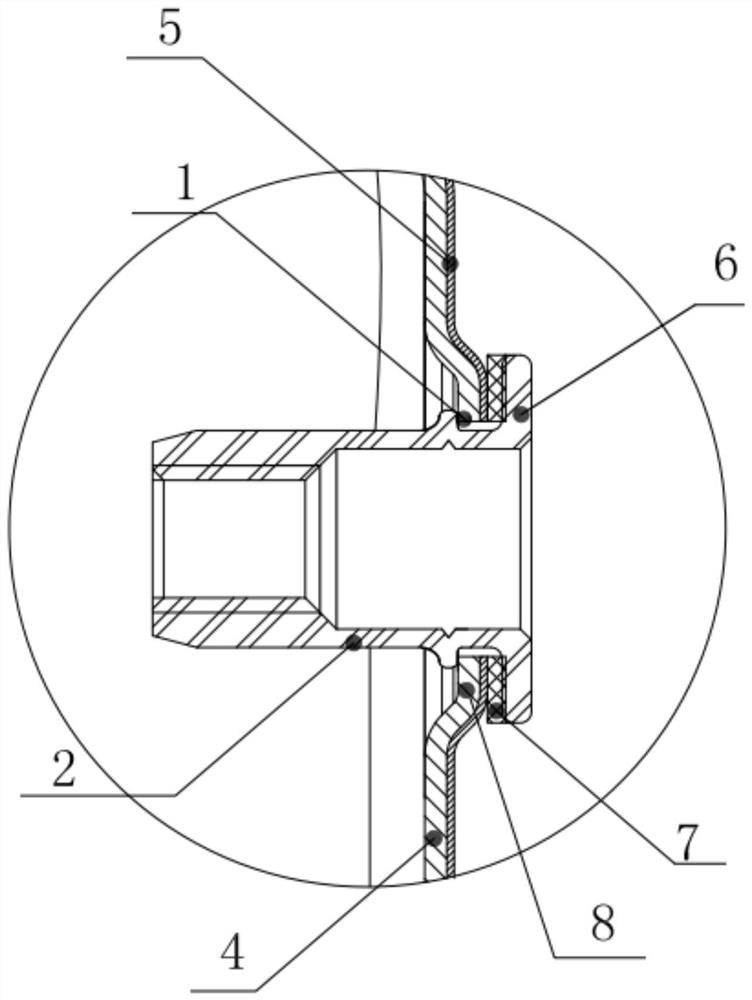

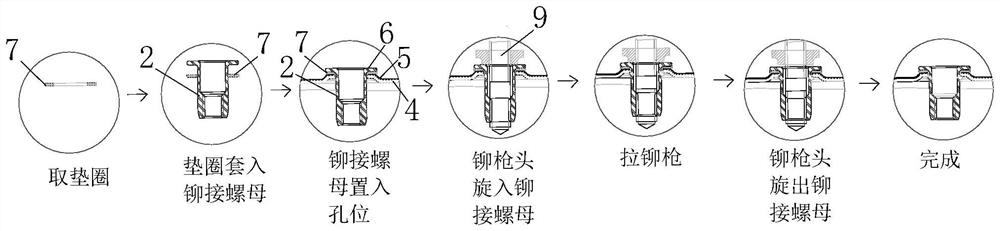

[0040] The inner tank riveting structure disclosed in this embodiment, Figure 1-Figure 2 As shown, it includes a hole 1 and a riveting nut 2, the hole 1 runs through the substrate and the enamel layer 5 of the inner container 4 of the household appliance 3, the riveting nut 2 is embedded in the hole 1, that is, the riveting nut 2 is stable It is fixed inside the hole 1 so that the riveting nut 2 is arranged on the enamel layer 5 of the inner liner 4 . figure 2 As shown, the opening of the rivet nut 2 is turned outward to form a retaining edge 6, figure 2 As shown, the retaining edge 6 presses against the opening periphery of the hole 1 , and the opening periphery is the enamel layer 5 , that is, the retaining edge 6 presses against the enamel layer 5 at the opening periphery of the hole 1 . A washer 7 is sandwiched between the opening periphery of the hole 1 and the retaining edge 6, the washer 7 is set on the riveting nut 2, and the inner ring wall of the washer 7 seals t...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the surface of the enamel layer 5 protrudes outward by 1.1mm to form the boss 8, the thickness of the gasket 7 is 0.6mm, and the silicone gasket 7 is resistant to Temperature above 225°C, the Shore hardness of the silicone gasket 7 is 65°C, and the distance across the sides of the regular hexagon at the hole position 1 is preferably set to 7mm. Other components and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the surface of the enamel layer 5 protrudes outward by 1mm to form the boss 8, the thickness of the gasket 7 is 0.5mm, and the silicone gasket 7 is temperature-resistant. Above 225°C, the Shore hardness of the silicone gasket 7 is 60°C, and the distance across the sides of the regular hexagon at the hole position 1 is preferably set to 6.5mm. Other components and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com