Method for measuring internal stress of concrete structure

A technology of concrete structure and internal stress, which is applied in the measurement of force, the measurement of force by measuring the frequency change of the stressed vibration element, the measurement device, etc., can solve the problems of difference, stress detection error of concrete members, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-12 The application is described in further detail.

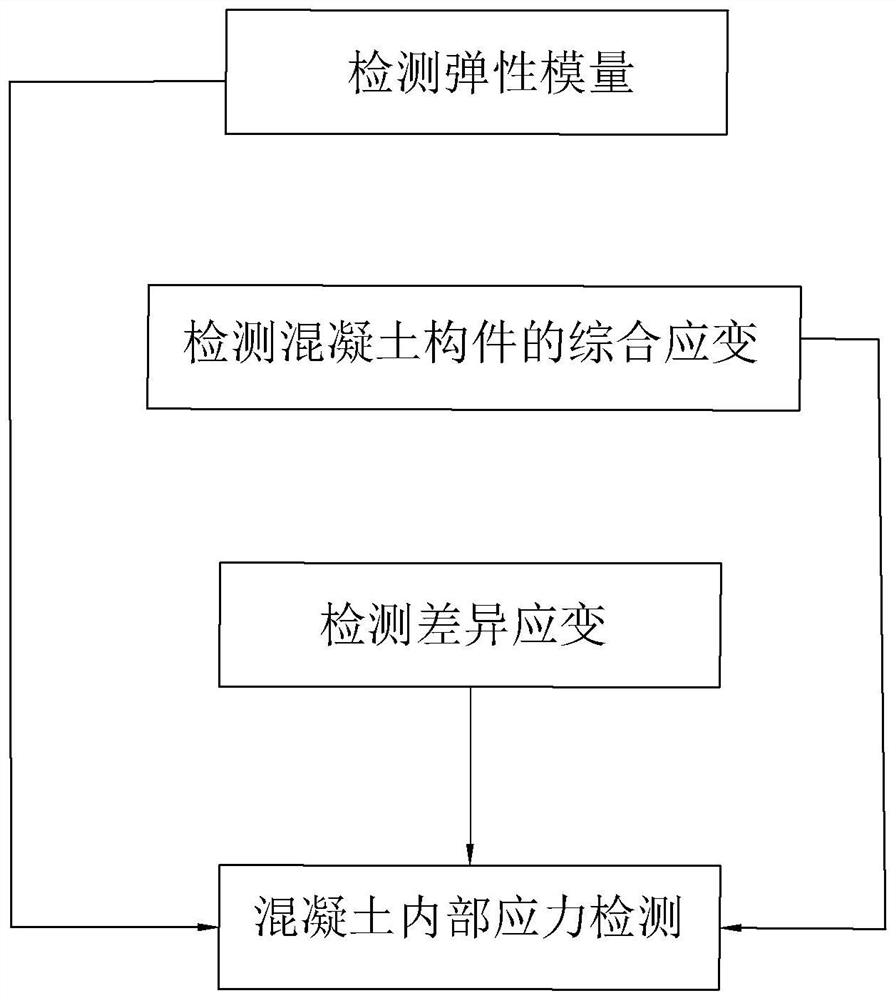

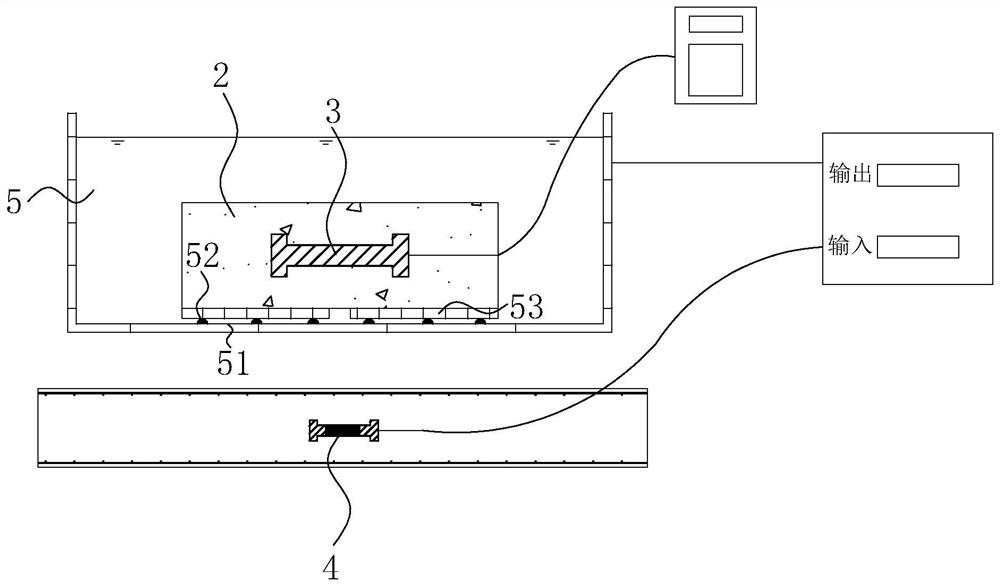

[0047] The embodiment of the present application discloses a method for measuring internal stress of a concrete structure. refer tofigure 1 and figure 2 , a method for measuring the internal stress of a concrete structure comprises the following steps:

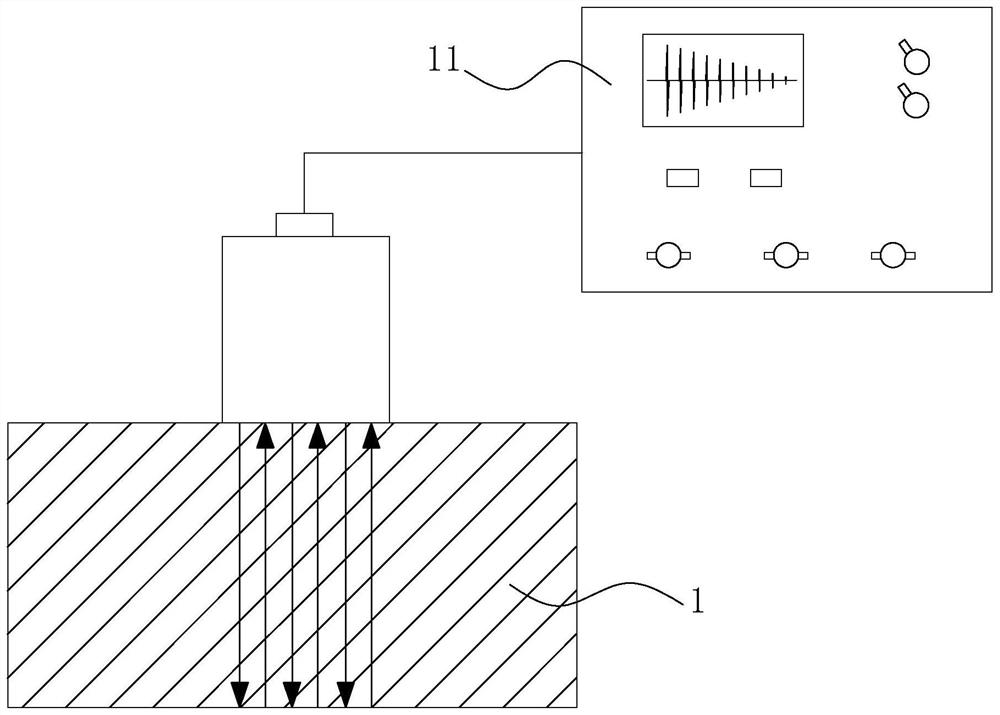

[0048] Detect elastic modulus: use concrete with the same ratio as the concrete component to make the first concrete sample 1, and perform the same maintenance as the concrete component on the construction site, conduct an ultrasonic test through a non-metallic ultrasonic detector 11, and measure the first concrete sample 1 Tensile modulus E of different ages (t) ;

[0049] The specific steps are as follows: the first concrete test piece 1 is produced in multiples, three are set in the embodiment of the present application, and the specification of the first concrete test piece 1 is 550*100*100mm, the first concrete test piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com