Method and device for predicting development effect of shale gas well

A development effect, shale gas well technology, applied in the field of oil and gas exploration and development, can solve problems such as inability to apply, and achieve the effect of avoiding necessity and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

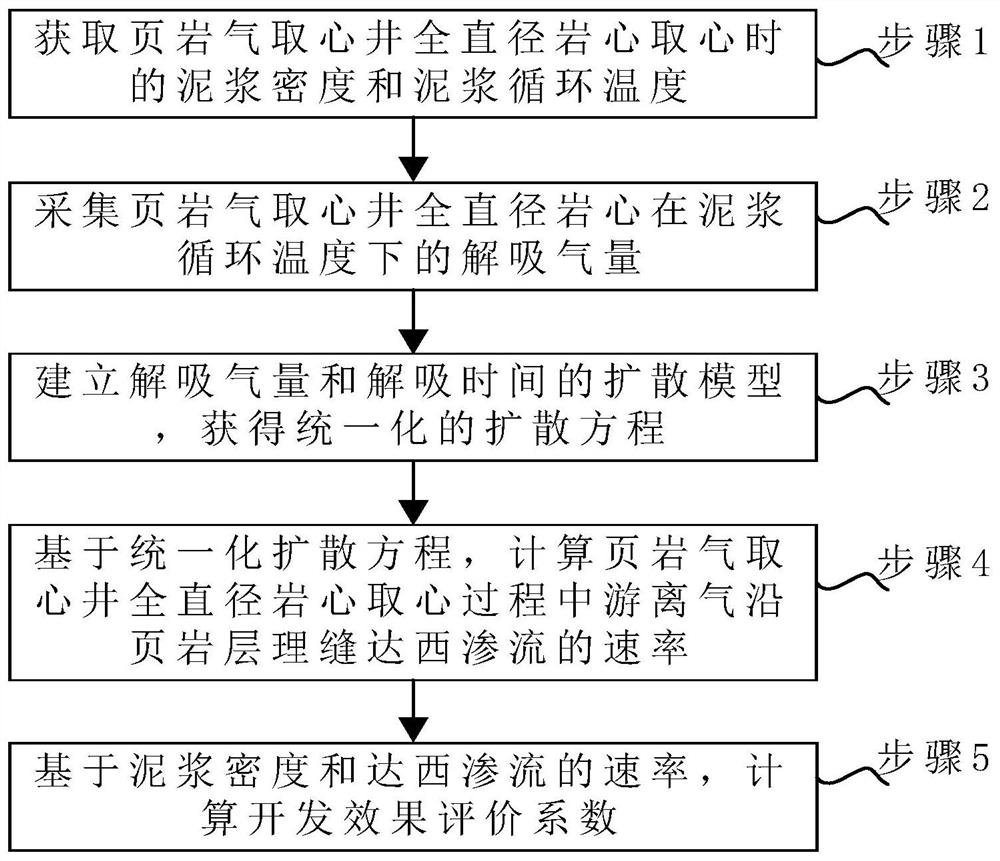

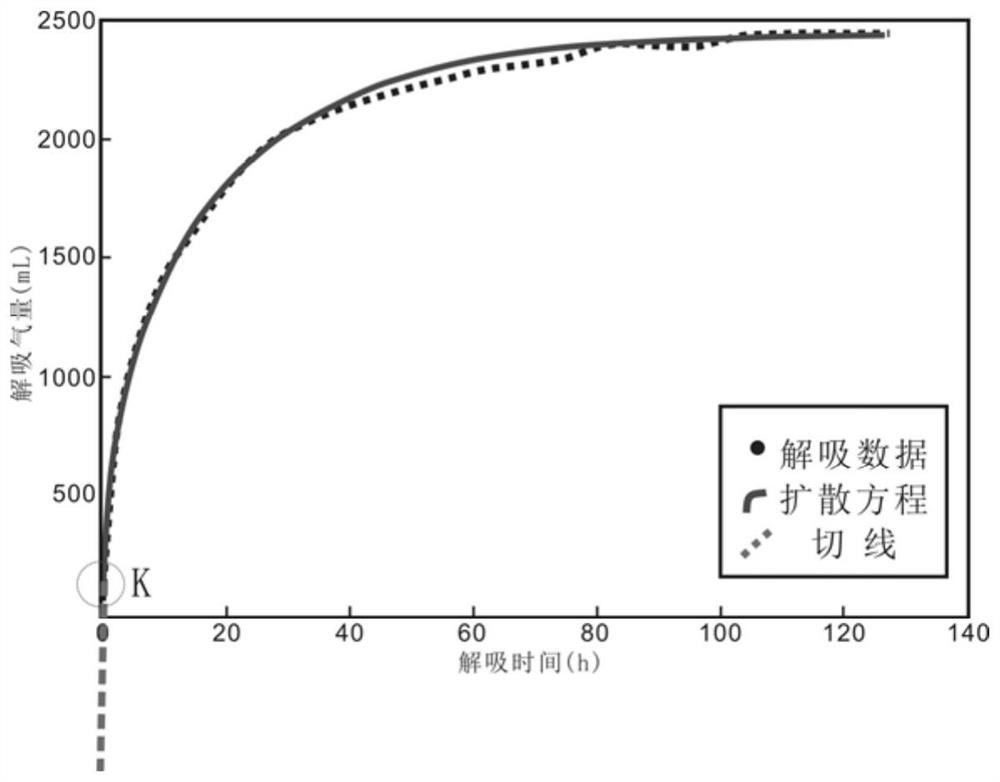

[0070] figure 1 A flow chart of a method for predicting the development effect of a shale gas well according to an embodiment of the present invention is shown. figure 2 A schematic diagram showing a slope obtained by a diffusion model based on desorbed gas volume and desorbed time in a method for predicting the development effect of shale gas wells according to an embodiment of the present invention.

[0071] combine figure 1 with figure 2 As shown, the prediction method for the development effect of shale gas wells includes:

[0072] Step 1: Obtain the mud density and mud circulation temperature when the full-diameter core of the shale gas coring well is taken;

[0073] Step 2: Collect the desorbed gas volume of the full-diameter core of the shale gas coring well at the mud circulation temperature;

[0074] Step 3: Establish a diffusion model of desorption gas volume and desorption time, and obtain a unified diffusion equation;

[0075] Among them, the unified diffusi...

Embodiment 2

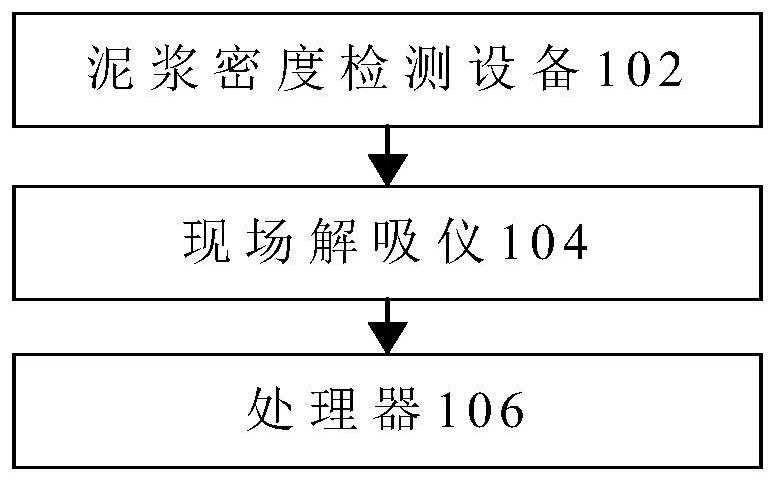

[0099] image 3 A block diagram of a device for predicting the development effect of shale gas wells according to an embodiment of the present invention is shown.

[0100] Such as image 3 As shown, the prediction device for the development effect of shale gas wells includes:

[0101] The mud density detection device 102 is used to obtain the mud density when the full-diameter core of the shale gas coring well is taken;

[0102] The on-site desorption instrument 104 collects the desorption gas volume of the full-diameter core of the shale gas coring well at the mud circulation temperature;

[0103] Processor 106, the processor is connected with the on-site desorption instrument, and the processor performs the following steps: establish a diffusion model of desorption gas volume and desorption time, and obtain a unified diffusion equation; The Darcy seepage rate of free gas along the shale bedding fractures during coring of diameter cores; based on the mud density and Darcy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com