Ship shafting machining and positioning tool

A technology for positioning tooling and shafting, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems that shafts with different diameters cannot be adjusted, the scope of application is small, labor-intensive efficiency, etc., to save the time of repeatedly moving the device, The effect of stable and accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

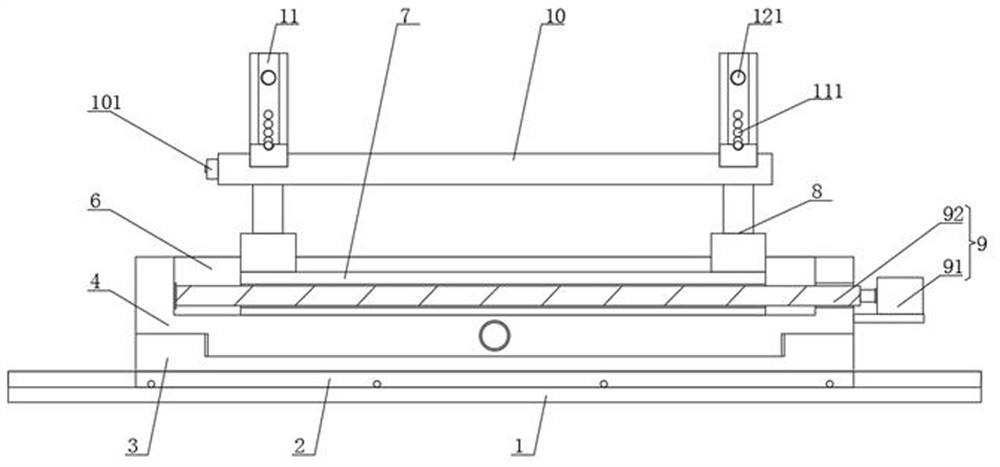

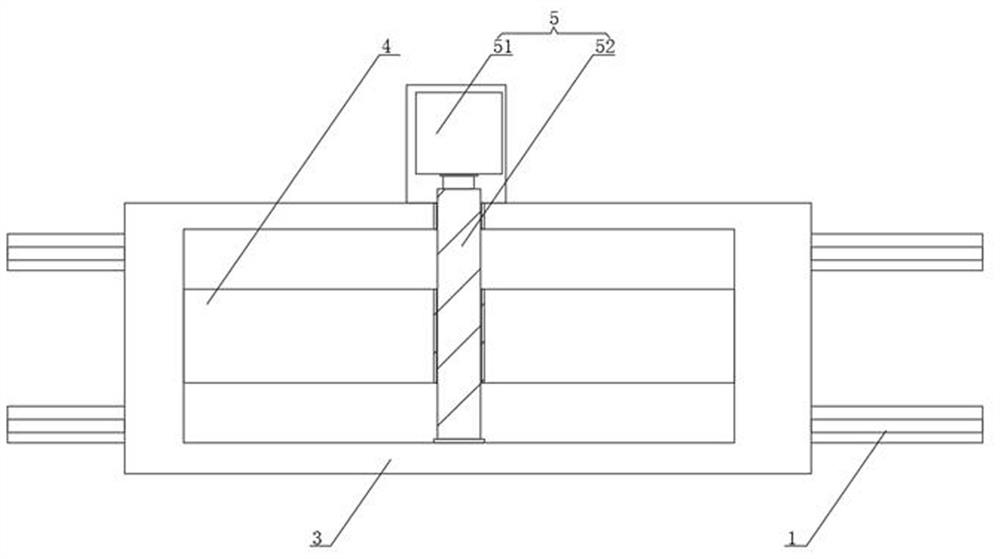

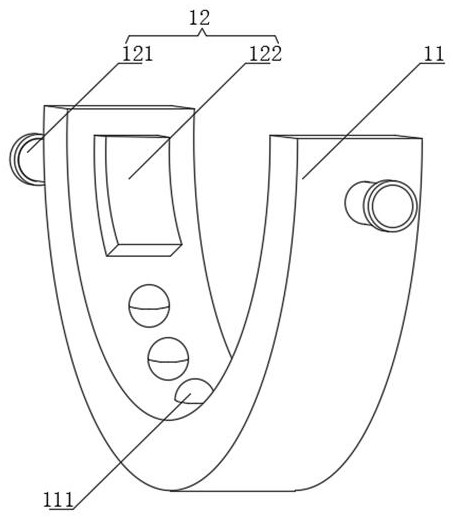

[0020] see Figure 1~3 , a ship shafting processing and positioning tool, including two parallel rails 1, a driving mechanism 2 is installed on the top between the two rails 1, the top of the driving mechanism 2 is fixedly connected to a base 3, and the top of the base 3 is slidably connected There is a vertical movement platform 4, and the back of the base 3 is provided with a first driving assembly 5, the first driving assembly 5 cooperates with the longitudinal movement platform 4, and the top of the longitudinal movement platform 4 is provided with a horizontal groove 6, and the inside of the horizontal groove 6 is slidingly connected There is a movable block 7, and the top of the movable block 7 is fixedly connected with two hydraulic cylinders 8, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com