Intelligently-manufactured gas bag plate clamping mechanism of computer to plate

A technology of intelligent manufacturing and plate making machine, applied in the direction of plate preparation, printing, etc., can solve the problems of CTP board adjustment, large restrictions, uneven force on the CTP board, etc., to achieve the effect of strong practicability and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

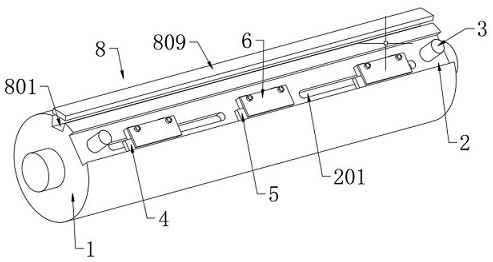

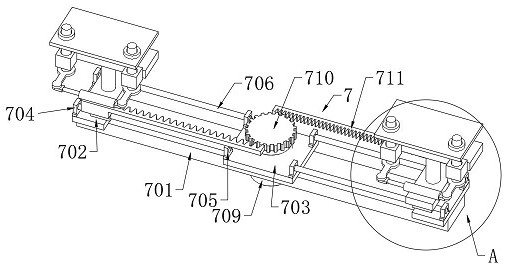

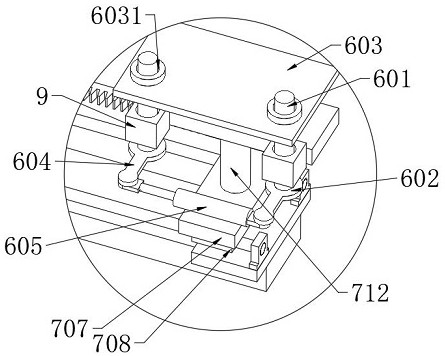

[0030] Please refer to the attached Figure 1-5 , an intelligently manufactured direct plate-making machine airbag plate clamping mechanism, including: a roller 1, a limit column 3, a pair of clamping plates 4, a fixed plate 5, a front pressing part 6, a driving device 7 and a rear pressing part 8.

[0031] Wherein, there is a front chute 2 along the length direction on the roller 1, and a pair of bar-shaped grooves 201 are opened in the front chute 2, and both sides of the front chute 2 are fixedly installed with limiting posts 3.

[0032] Further, the inside of the set roller 1 is a cavity structure, and a pair of bar-shaped grooves 201 opened in the front chute 2 are in a state of communication with the cavity structure inside the roller 1, and the set of a pair of limit posts 3 are respectively Located on both sides of the front chute 2 along the length direction, it serves as a limit function for the maximum stroke of the front pressed part 6 .

[0033] Wherein, a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com