Guide rail for elevator system and elevator system

A technology of elevator system and elevator guide rail, which is applied in the direction of transportation and packaging, sounding equipment, instruments, etc., can solve the problems that affect the user's riding experience, the elevator guide rail is prone to rust, and the elevator safety factor is reduced, so as to ensure stability and improve Experience, improve the effect of processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

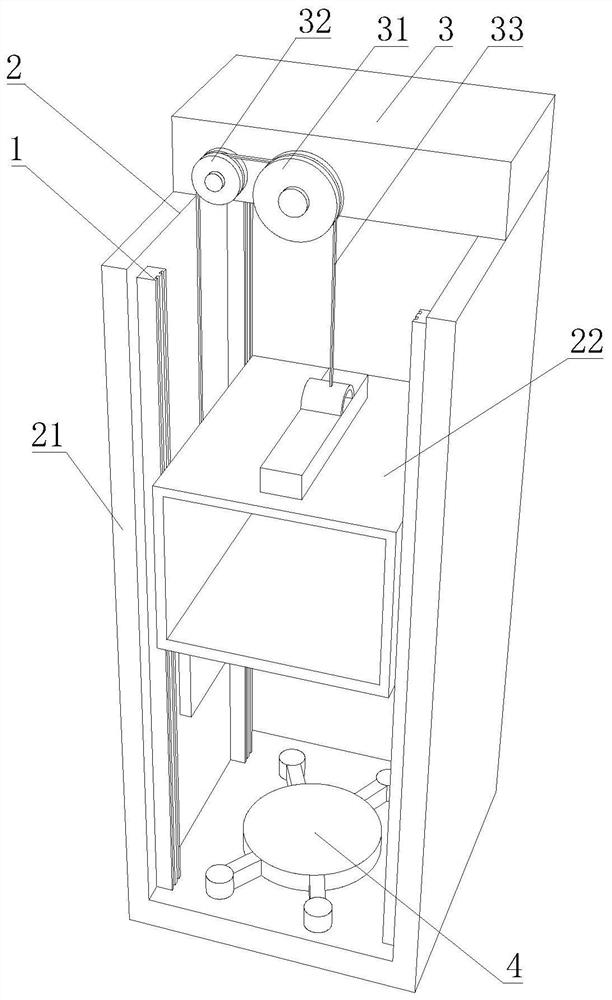

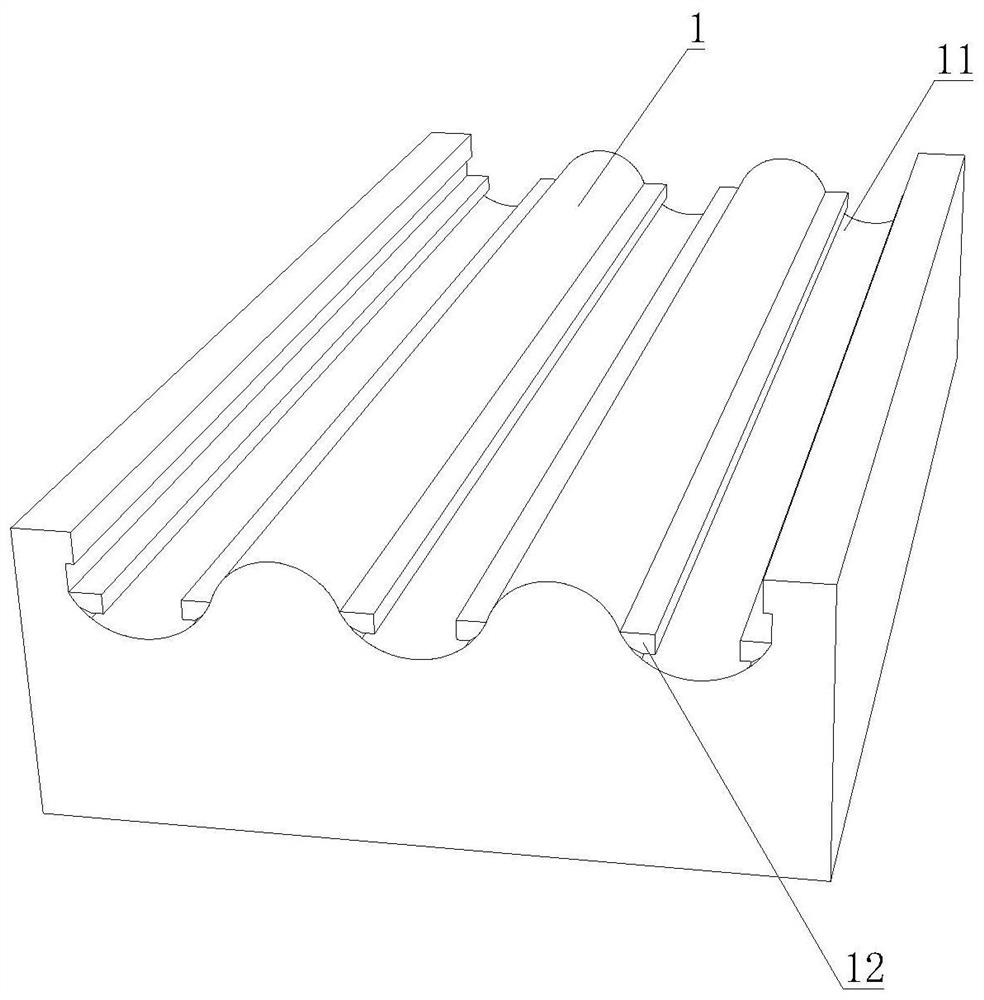

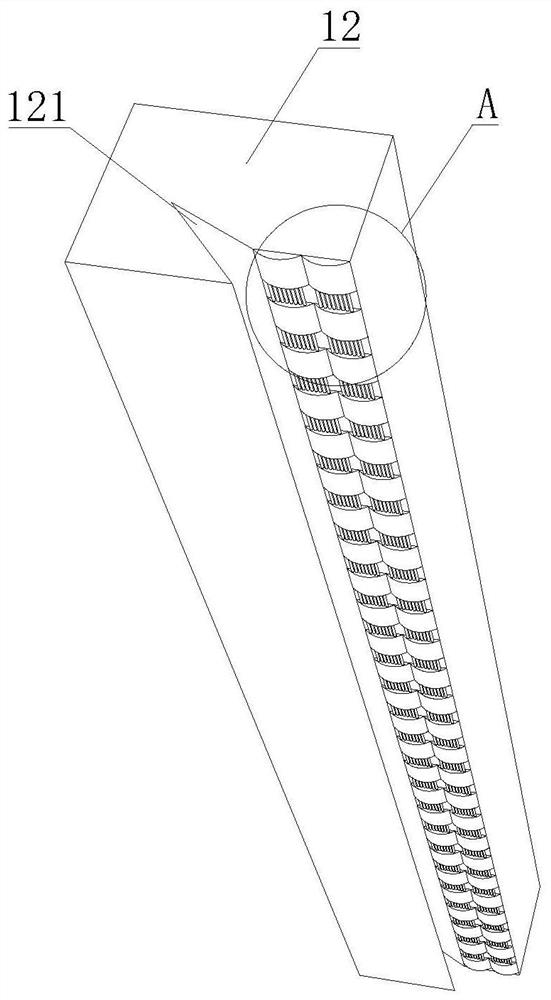

[0052] Such as Figure 1-12 As shown, the present invention provides a guide rail for an elevator system, including an elevator guide rail main body 1, a recessed part 11 is arranged on the outer surface of the elevator guide rail main body 1, and a reinforcing plate 12 is fixedly installed on the inner wall of the recessed part 11 to reinforce The inner side of the plate 12 is provided with a locking groove 121, and the inner side of the reinforcement plate 12 is provided with a self-lubricating mechanism a and a noise reduction mechanism b, the self-lubricating mechanism a includes a lubricating pocket, and the interior of the lubricating pocket is provided with a lubricating storage plate a1 , the interior of the lubricating storage plate a1 is provided with a heat conduction pipe a131 and a grease plate a132, the noise reduction mechanism b includes a noise reduction sleeve column, and a noise reflection plate b2 is arranged inside the noise reduction sleeve column, and the...

Embodiment 2

[0055] Such as Figure 1-12 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the two ends of the noise reduction sleeve are fixedly connected to the outer surface of the lubricating capsule, and the middle part of the inner cavity of the noise reduction sleeve is fixedly installed with The middle column b1, one end of the noise reflection plate b2 is fixedly connected to the outer surface of the middle column b1, the other end of the noise reflection plate b2 is fixedly connected to the inner surface of the noise reduction sleeve column, and the sound-absorbing plate b21 is evenly distributed on the noise reflection plate b2 On the outer surface of the sound-absorbing plate b21, a noise-disturbing column b22 is fixedly connected to the outer surface of the sound-absorbing plate b21, and a noise-attenuating plate b23 is fixedly installed in the middle of the outer surface of the sound-absorbing plate b21. b21 fixed connect...

Embodiment 3

[0058] Such as Figure 1-12 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a diamond-shaped noise slow-flow cavity b24 is opened on the outer surface of the noise attenuation plate b23, and the inner wall of the diamond-shaped noise slow-flow cavity b24 is fixed It is connected with a special-shaped sound-proof damping felt b241, which is evenly distributed on the inner wall of the diamond-shaped noise slow flow chamber b24, and the top of the special-shaped sound-proof damping felt b241 is provided with a sound-absorbing groove b242, and the sound-absorbing groove b242 is about the center of the special-shaped sound-proof damping felt b241 The line is symmetrically arranged, and the sound-absorbing cotton board b243 is fixedly installed inside the special-shaped sound-absorbing damping felt b241. The sound-absorbing cotton board b243 is evenly distributed on the inner surface of the special-shaped sound-absorbing dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com