Sorghum and passion fruit raw material brewing method

A passion fruit and sorghum technology, applied in the field of sorghum passion fruit raw material brewing, can solve the problems of reducing the saccharification conversion rate, consuming amylase, and reducing the yield of wine, so as to improve the degree of enzymatic hydrolysis reaction, improve the binding tightness, reduce the The effect of energy expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

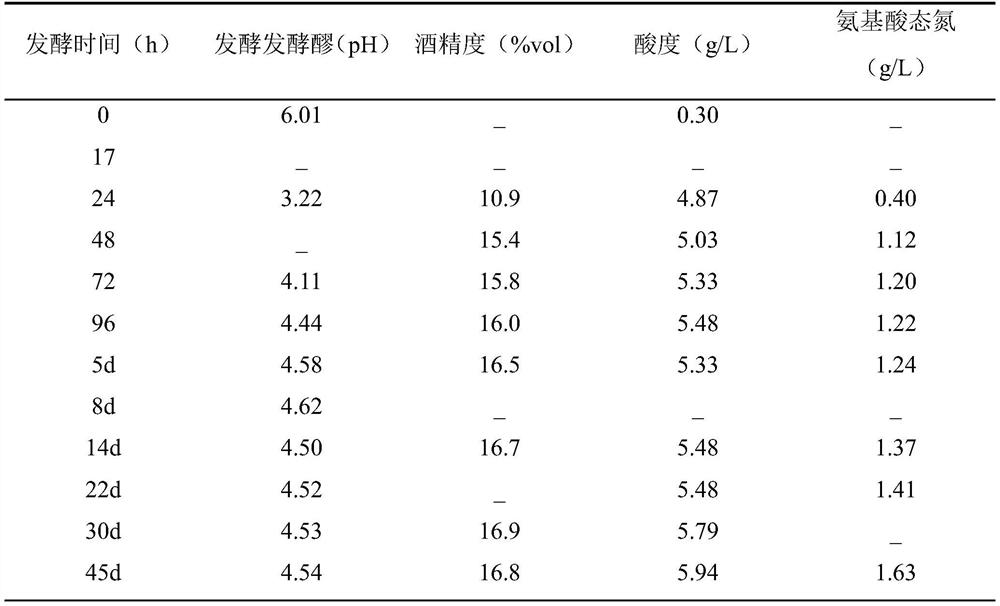

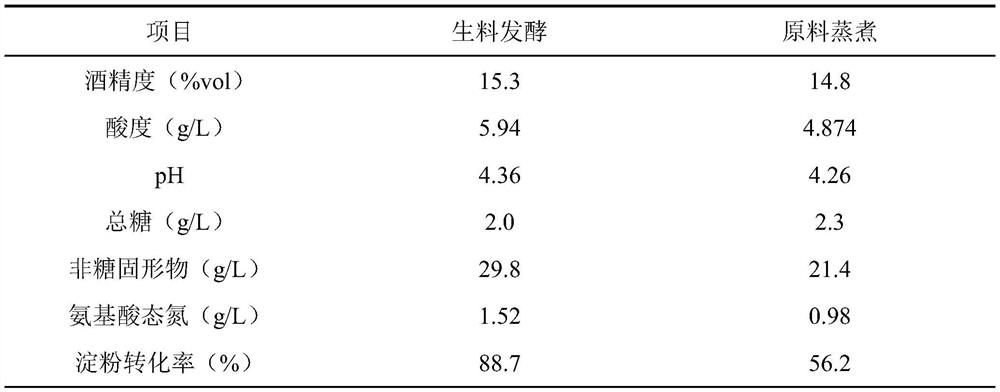

Embodiment Construction

[0053] The embodiments of the present invention will be described in detail below. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0054] The raw materials used in the present invention, unless otherwise specified, are conventional commercially available products; the methods used in the present invention, unless otherwise specified, are conventional methods in the art.

[0055] A method for brewing sorghum passion fruit raw material, the steps are as follows:

[0056] (1) Raw material preparation

[0057] Select sorghum without mildew and no insects as raw materials for winemaking; select passion fruit without insect disease and decay as raw materials for fruit winemaking; select distiller's yeast, β-sweet neral, D-mannitol, dimethyl succinate As raw material; select α-amylase, glucoamylase, pectinase as enzyme preparation raw material; select active Saccharomyces cerevisiae as ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com